Polymer processing system including compression chamber and method for using same

a technology of polymer processing and compression chamber, which is applied in the direction of sweetmeats, dough shaping, food shaping, etc., can solve the problems of reducing the value of the product, visual appearance of the mark, blemishes and the like, etc., and achieves the effect of reducing the extrusion mark, reducing production rates, and increasing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention relates to systems for processing polymeric materials.

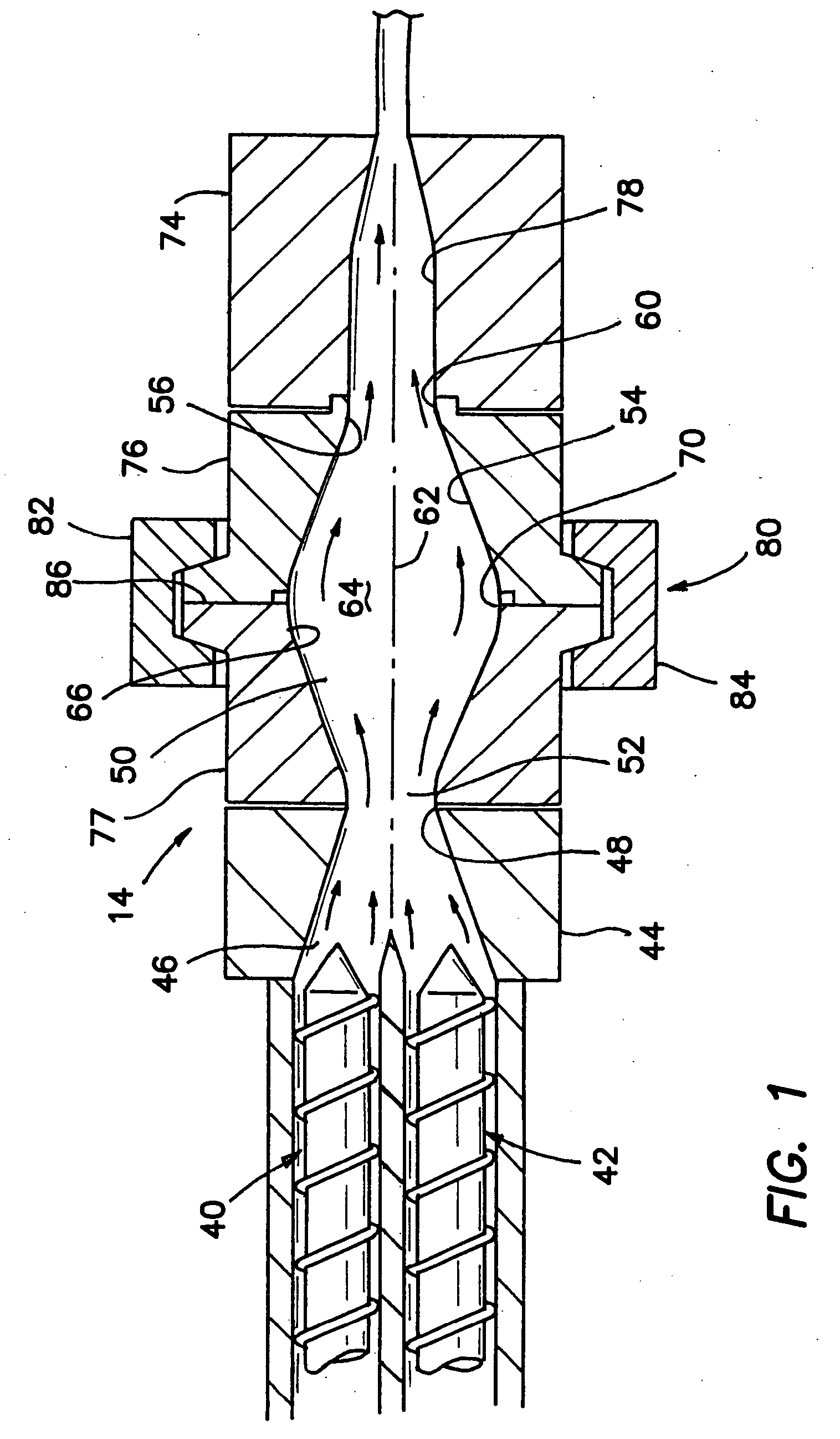

[0033] Although any suitable type of polymeric material may be processed using the present systems, advantageously thermoplastic polymeric materials effective to be die formed into products, such as sheets, films and the like shapes, are used. FIG. 1a is a schematic view showing one embodiment of such a system in accordance with the present invention. In FIG. 1A, the system 10 includes a polymer extrusion assembly 12, a decompression chamber assembly 14 and a die assembly 16. The result of processing a polymeric material through the system is a shaped polymer product 18.

[0034] The polymer extrusion assembly 12 may be any suitable polymer extrusion assembly, for example, a conventional or substantially conventional assembly, such as an extrusion assembly including one or two or more conventional or substantially conventional screw extruders. The function of polymer extrusion assembly 12 is to produce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com