Cracking tube having helical fins

a technology of helical fins and cracking tubes, which is applied in the direction of indirect heat exchangers, furnaces, lighting and heating apparatus, etc., can solve the problems of reducing the coefficient of heat transfer, reducing the fraction of hydrocarbons produced in excess, and reducing the pressure loss of fluids, so as to achieve the effect of high efficiency and minimal fluid pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0051] Test Tubes T1 to T5 were prepared and checked for film heat transfer coefficient h (W / m2 / K) and pressure loss dP (Pa).

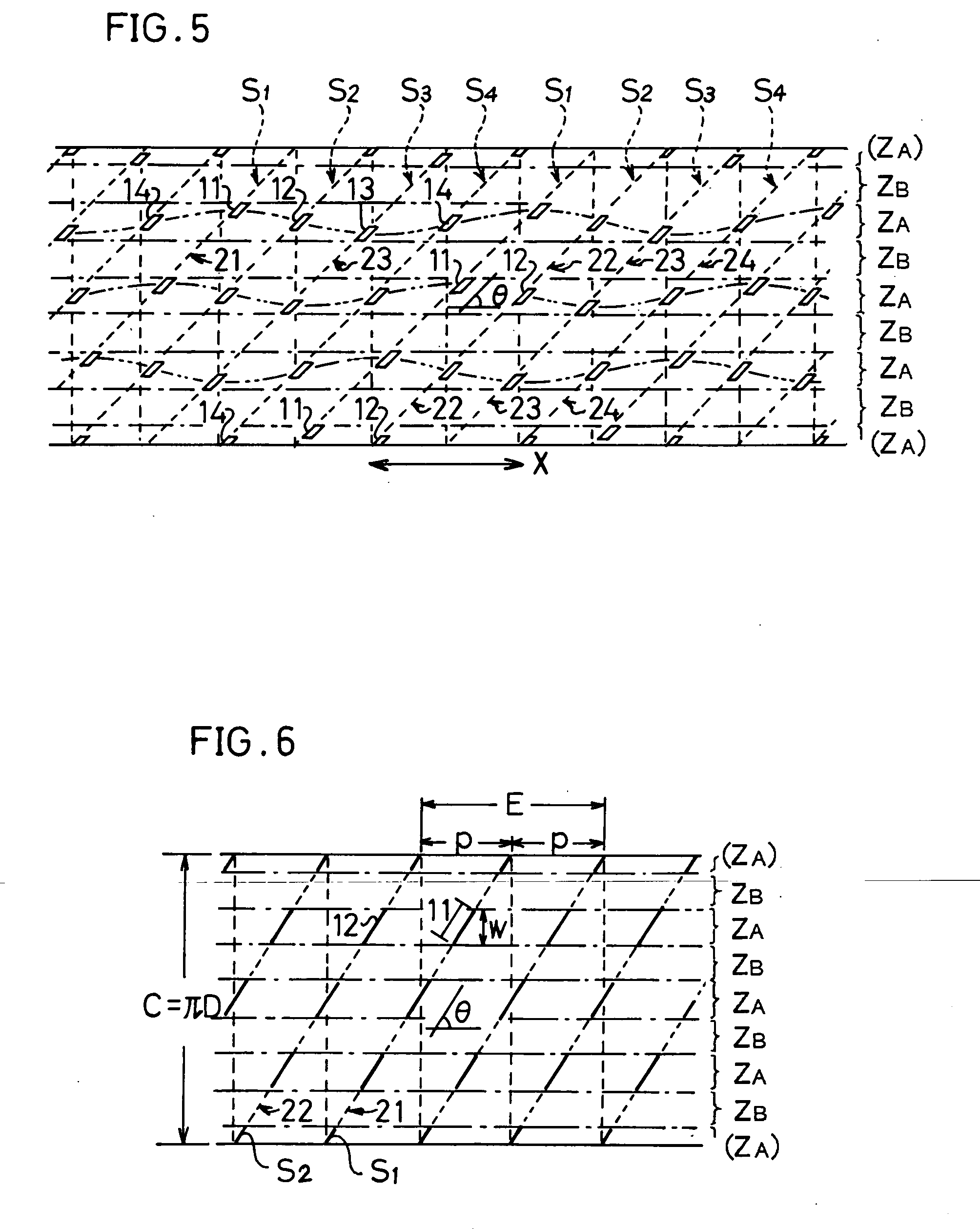

[0052] T1 is according to the invention, and T2 to T5 are comparative examples. Table 1 shows the particulars about these test tubes.

TABLE 1Test TubesFin SpecificationsCircum-CircularNumberferentialarcNumberof rowsAnglelengthlengthNumberperin circum-ofLengthof innerDraw-Thick-as pro-ofturn offerentialincli-ratioNo.I.D.surfaceingShapeHeightnessjectedhelixeshelixdirectionnationPitchR *NoteT142 mm132 mmFIG.Dis-2.2 mm8 mm16.5 mm14—60 deg76 mm0.5Inven-1crete,tionhelicalT242 mm132 mmFIG.Con-2.2 mm8 mm18.9 mm1——60 deg76 mm1.0Comp.12tinuous,ex.helicalT342 mm132 mmFIG.Dis-2.2 mm8 mm18.9 mm14 and 3—60 deg76 mm1.0Comp.13crete,alter-ex.helicalnating(stag-gered)T442 mm132 mmFIG.Paral-2.2 mm8 mm18.9 mm——8——0.5Comp.14lel to**ex.tubeaxisT542 mm132 mmNoneNo fin—————————Comp.ex.

(Note)

* Circular arc length ratio R = (sum of circular arc lengths of fins along every turn of he...

example 2

[0064] Next, a thermal fluid analysis was conducted using a W-shaped coil shown in FIG. 11 and simulating the conditions under which reactors are used for producing ethylene to determine pressure loss of the fluid inside the coil and yields of ethylene and propylene.

[0065] The coil shown in FIG. 11 includes tubes (straight tubular portions) which are 63.5 mm in inside diameter, 6.4 mm in wall thickness and 9.6 m in length and which provide a first pass, second pass, third pass and fourth pass, respectively, as arranged in this order from the upstream side downstream. Table 2 shows the construction of Test Tubes T6 to T9.

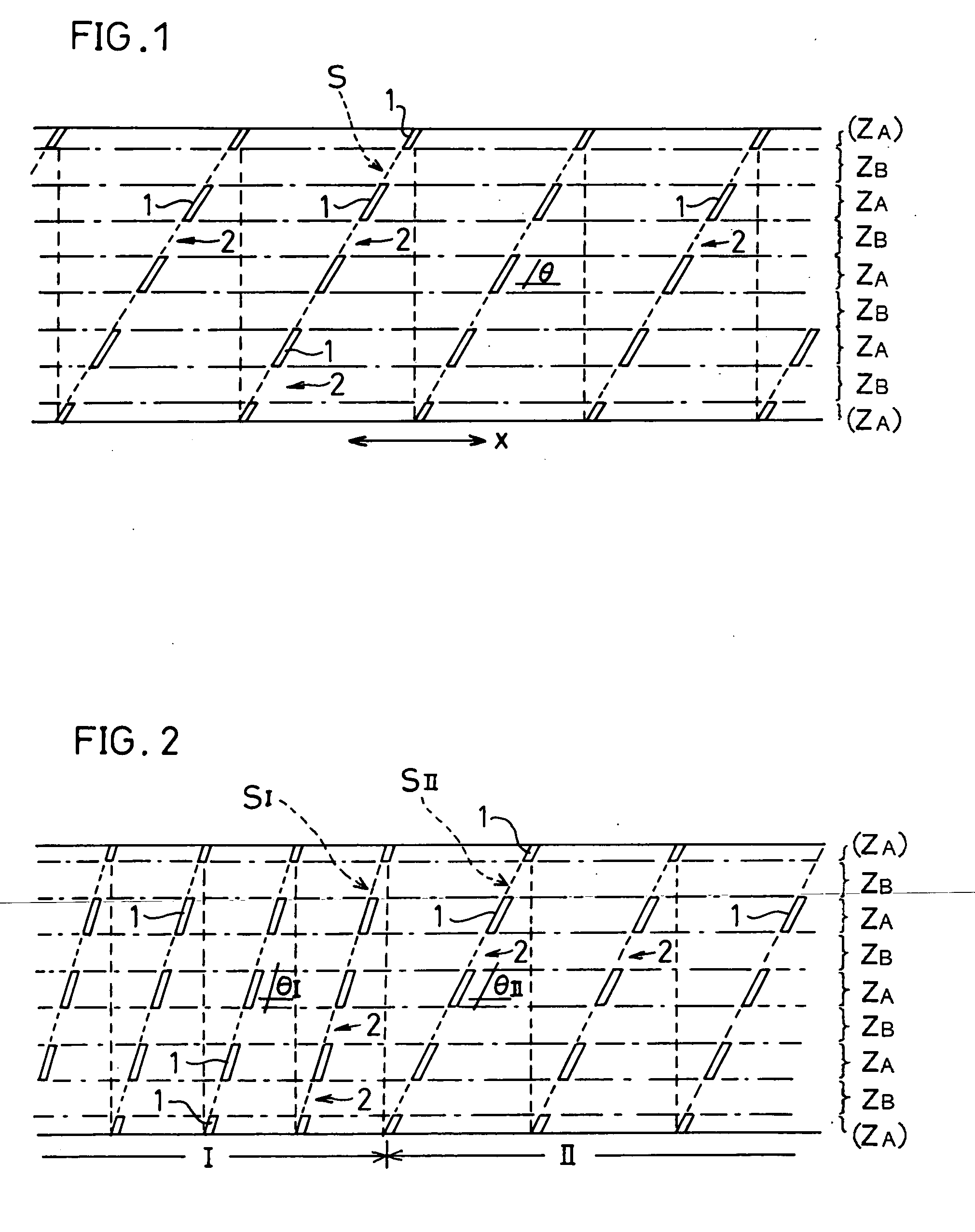

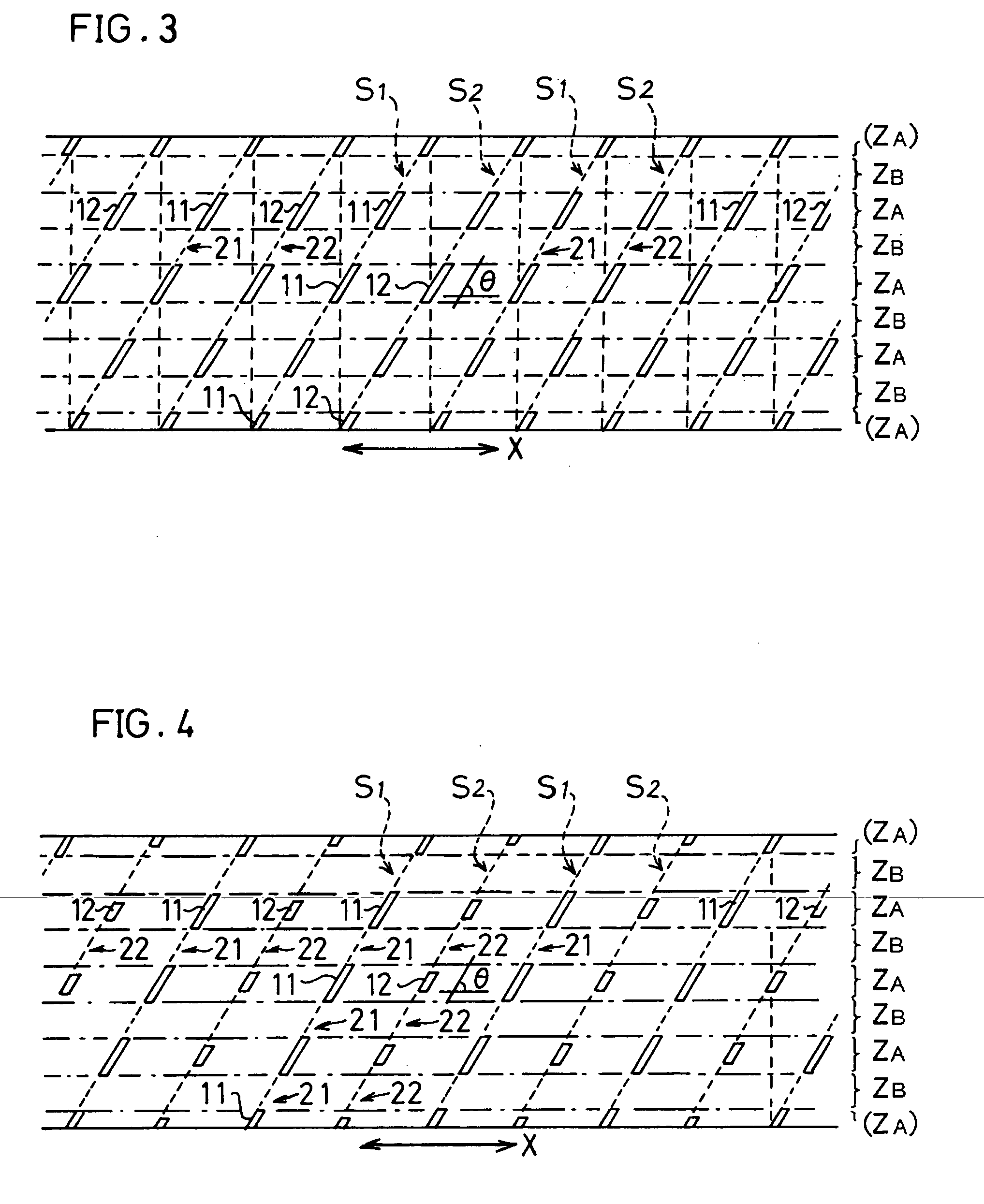

[0066] Test Tube T6 is according to the invention, and Test Tubes T7 to T9 are comparative examples. As to the arrangement of fins on the tube (straight tubular portion), Test Tube T6 is the same as is shown in FIG. 1, T7 as is shown in FIG. 13, and T8 as is shown in FIG. 12. T9 is an example which has no fins.

TABLE 2Test TubesStructure ofT 6T 7T 8T 9passes(Inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of inclination | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com