Container candle

a container candle and candle body technology, applied in the field of container candles, can solve the problems of considerable heat loss, uncomfortable or possibly excessive touch, etc., and achieve the effect of efficiently heating the surface, reducing the temperature of the wall, and complete and more rapid melting of the wax

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

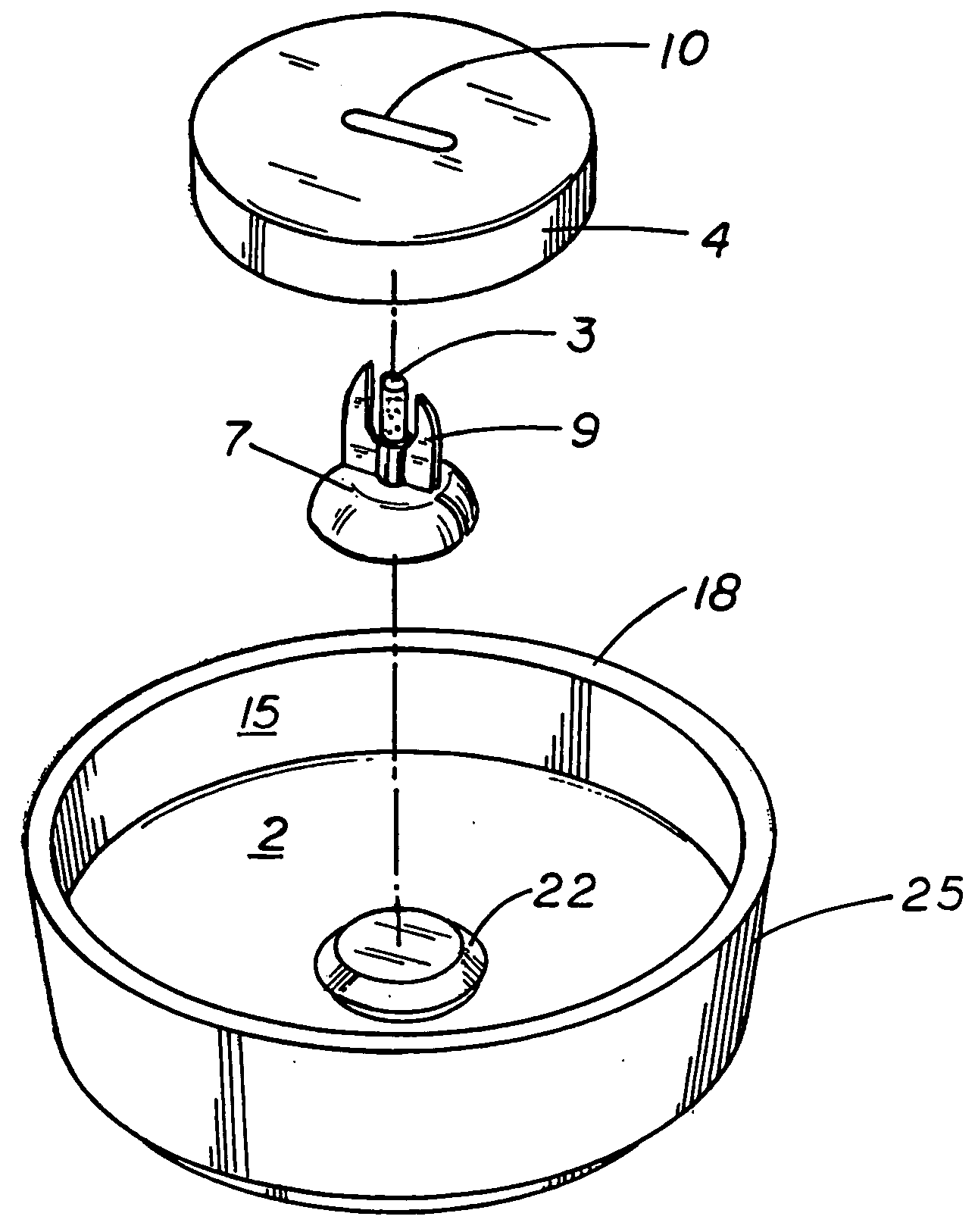

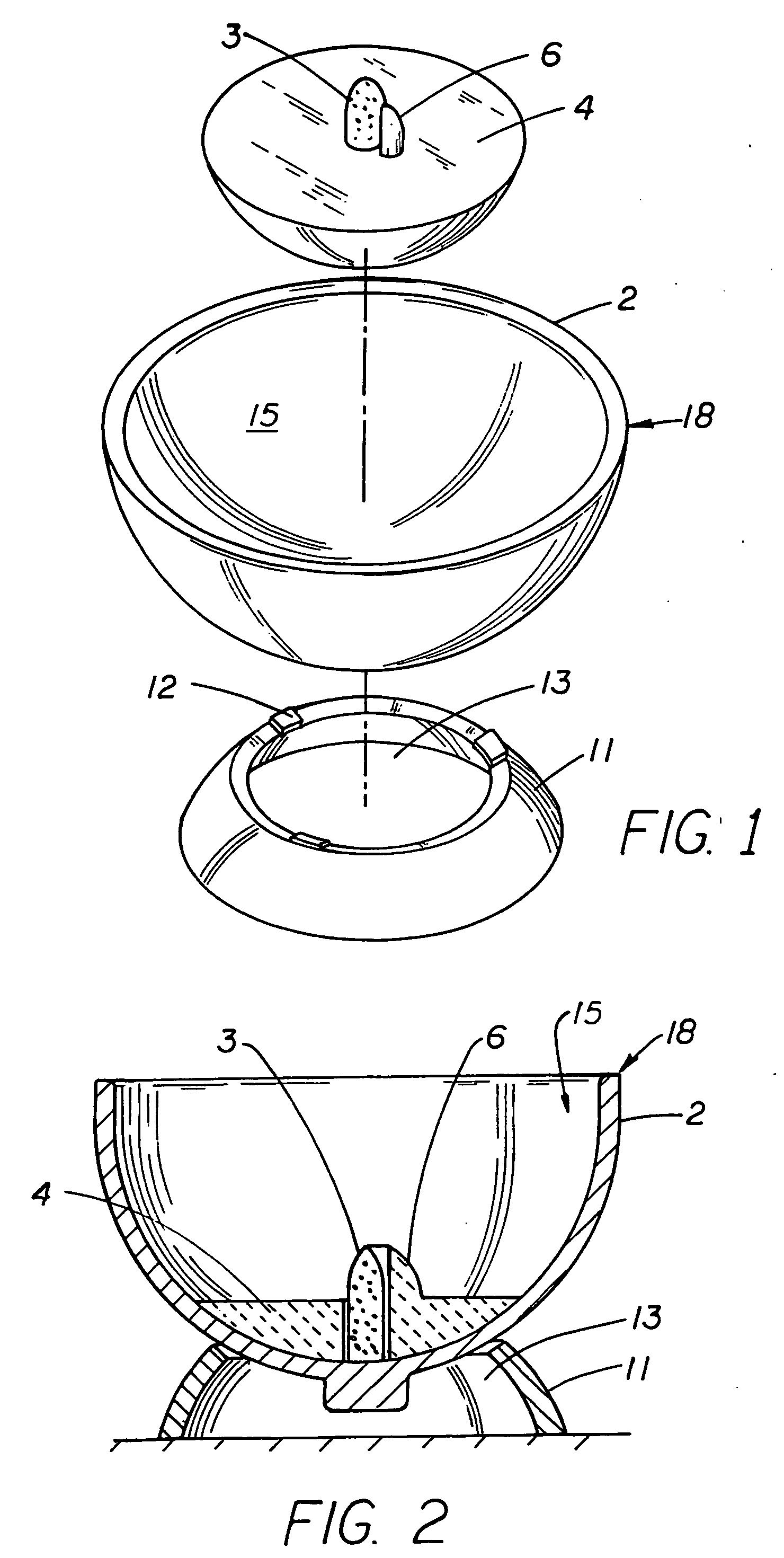

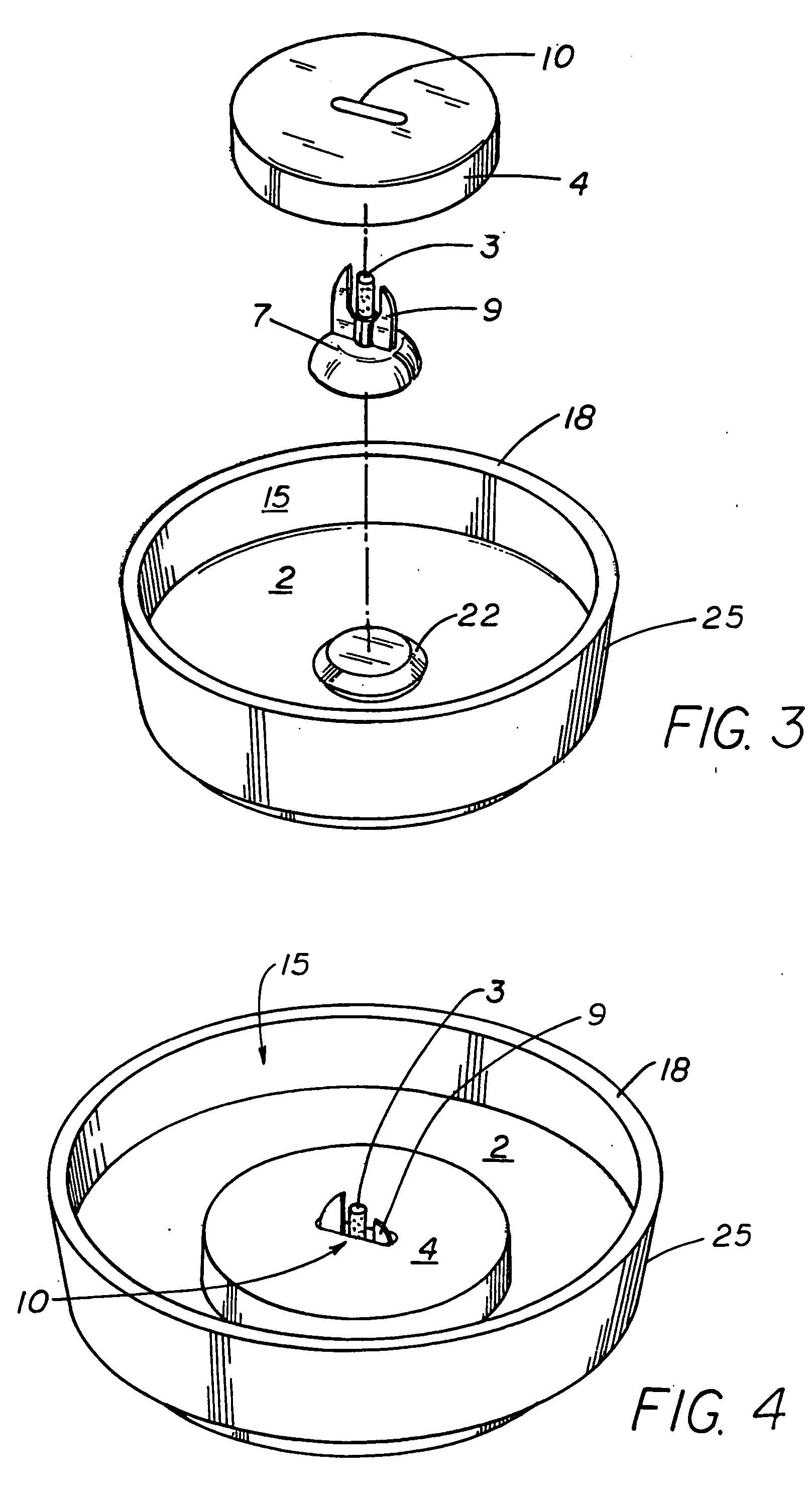

[0020] Ordinary candles comprise a vertical, self-supporting body or column of wax, with a substantially horizontal top and a central longitudinal wick which extends through and above the wax. The exposed portion of the wick above the solid wax is lighted by a flame, and the heat generated by the flame melts a small volume of the wax at the top of the candle, adjacent the wick, establishing a puddle or reservoir of molten wax to serve as fuel for the flame on the wick, and to release any volatile actives present therein. The capillary attraction of the molten wax and the wick, which is generally a structure of closely related fibers, causes the molten wax to travel through the wick to the flame, by which it is consumed. As the wax is consumed in this manner, the body of wax diminishes and the top surface thereof progressively lowers. The upper portion of the wick, extending above the lowering wax, is generally consumed by the flame. The flame in such a candle remains in the same pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com