Aluminum phosphate or polyphosphate particles for use as pigments in paints and method of making same

a technology of aluminum phosphate and polyphosphate, which is applied in the direction of phosphates, phosphorus oxyacids, phosphates, etc., can solve the problems of high cost of titanium dioxide pigment manufacturing, difficult to obtain refraction indices of its two forms, anatase and rutile, and limited options for pigment or paint manufacturing processes that result in a film containing “pores” in the internal part of the particle or between the particle and the resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example no.1

EXAMPLE NO. 1

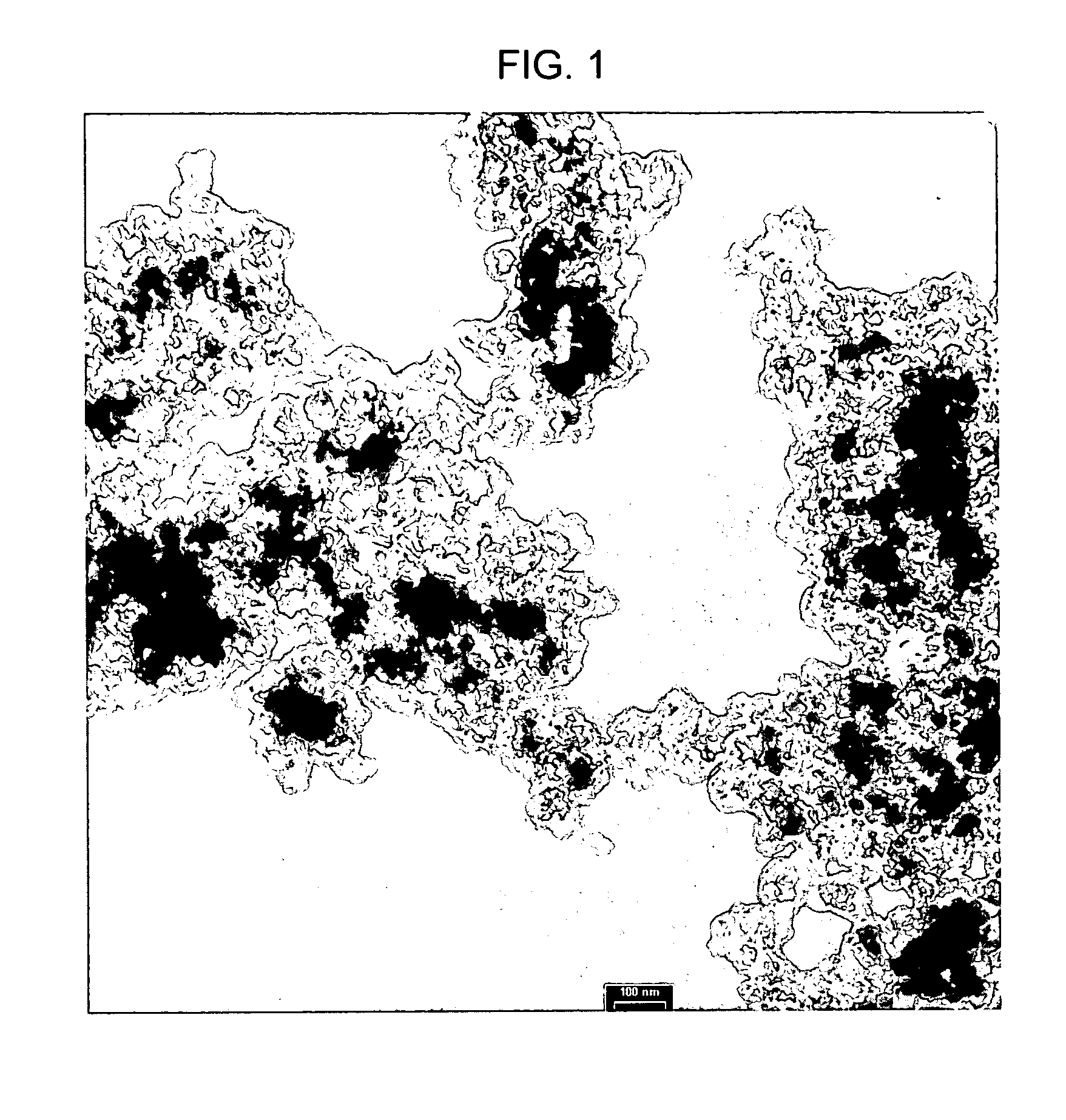

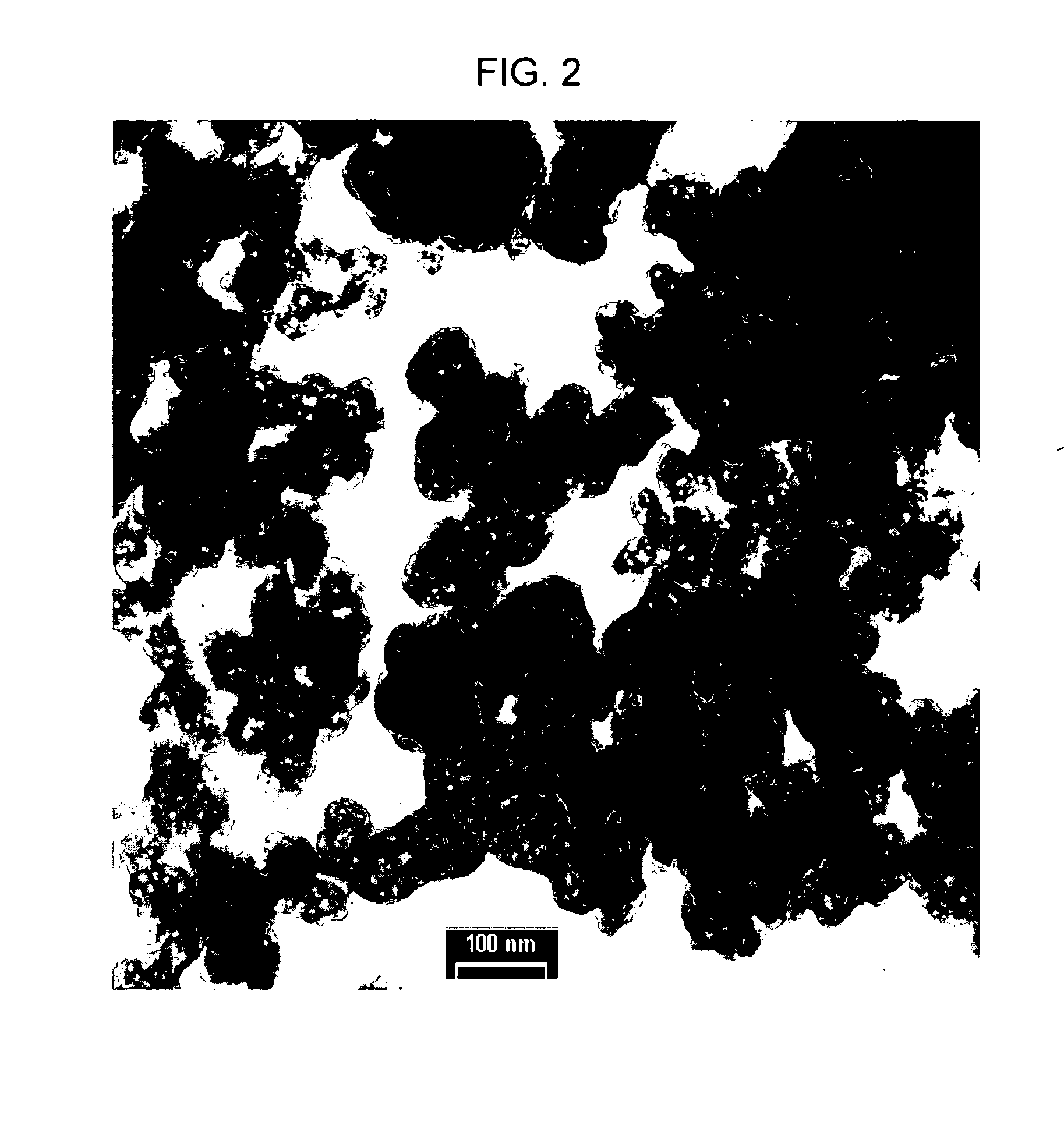

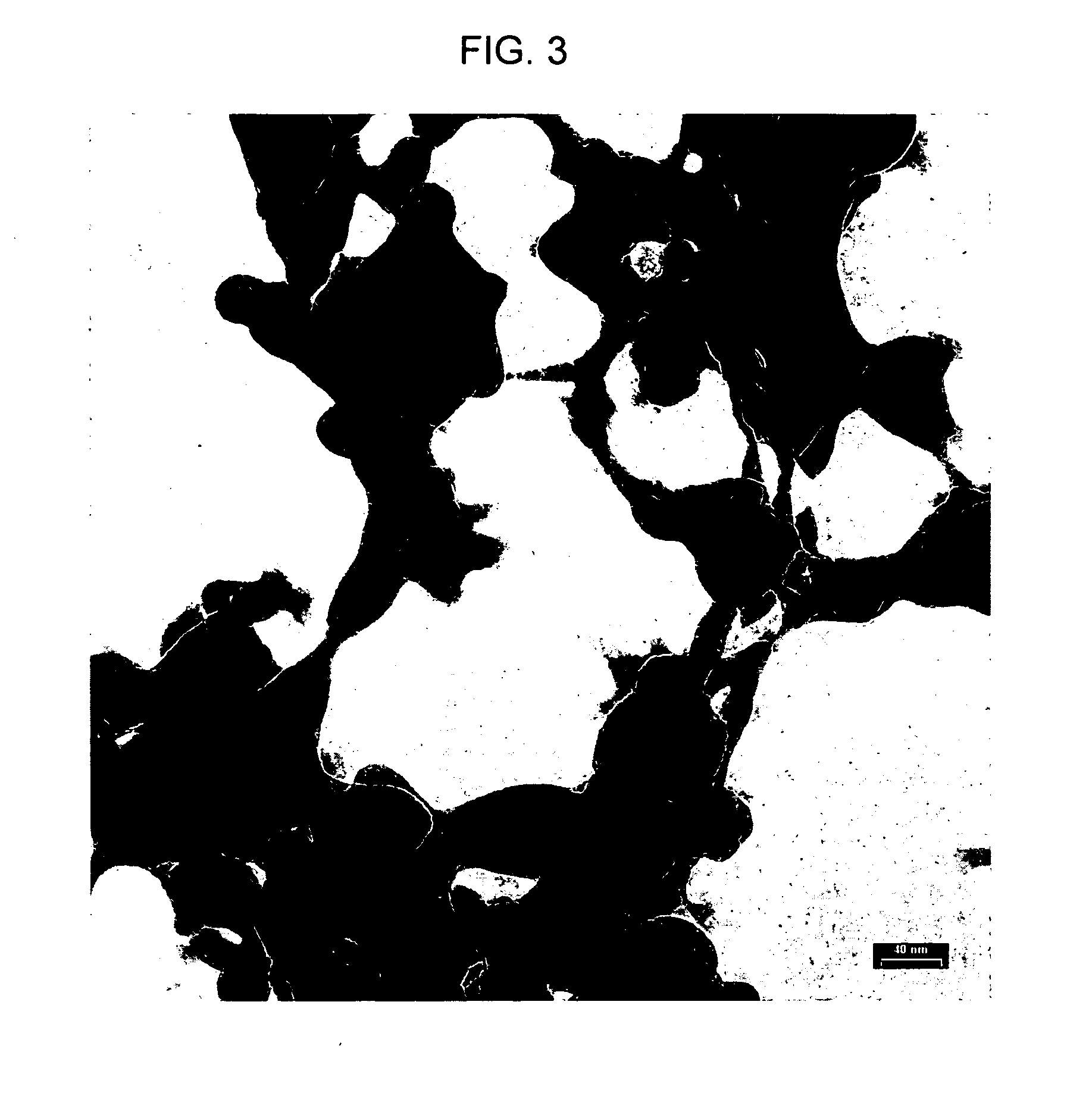

[0063] In this example, 535.0 kg of aluminum phosphate was prepared. The wet product was dried in a “turbo-dryer” and presented characteristics of hollow particles with 15% humidity and P:Al (phosphorus:aluminum) ratio of 1:1.50.

[0064] 940.0 kg of fertilizer phosphoric acid containing 55.0% of P2O5 was prepared. In the initial preparation phase, the acid discoloration was carried out, which lasted approximately thirty minutes, at a temperature of 85° C. For this phase, a solution with 8.70 kg of hydrogen peroxide containing around 50% of H2O2 was added to the acid. Then, the acid was diluted with 975.0 kg of process water, cooled to a temperature of 40° C. and then stored at the concentration of 27.0% of P2O5.

[0065] The aluminum source employed in this application was a commercial aluminum sulfate solution containing 28% of Al2O3. The solution was filtered and diluted with process water. Specifically, 884.30 kg of aluminum sulfate solution and 1,776.31 kg of process w...

example no.2

EXAMPLE NO. 2

[0070] From the results of Example No. 1, around 200 kg of dried and micronized aluminum phosphate was used. The sample was used for the manufacturing of a home paint sample. Initially, 900 liters of opaque white acrylic paint was prepared. Such paint was applied and the performance was evaluated in comparison with one of a commercially available paint. The basic composition of the paint based on an original formulation containing around 18% of titanium dioxide was as follows: aluminum phosphate was approximately 14.20%; titanium oxide was approximately 8.34%; kaolin was approximately 7.10%; algamatolite was approximately 10.36%; diatomite was approximately 0.84%; acrylic resin was approximately 12.25%, and PVC was approximately 47.45%. The characteristics of the paint prepared with aluminum phosphate, after the application of it in painting, was the as follows: a) wet coverage similar to the reference paint coverage; b) dry coverage was better than the coverage with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com