Magnetic oscillator, magnetic head, and magnetic recording and reproducing apparatus

a technology of magnetic oscillator and magnetic head, which is applied in the field of magnetic oscillator, magnetic head, and magnetic recording and reproducing apparatus, can solve the problems of not only the noise component, but also the pure signal component, and the noise is large, so as to achieve the effect of suppressing magnetic white nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

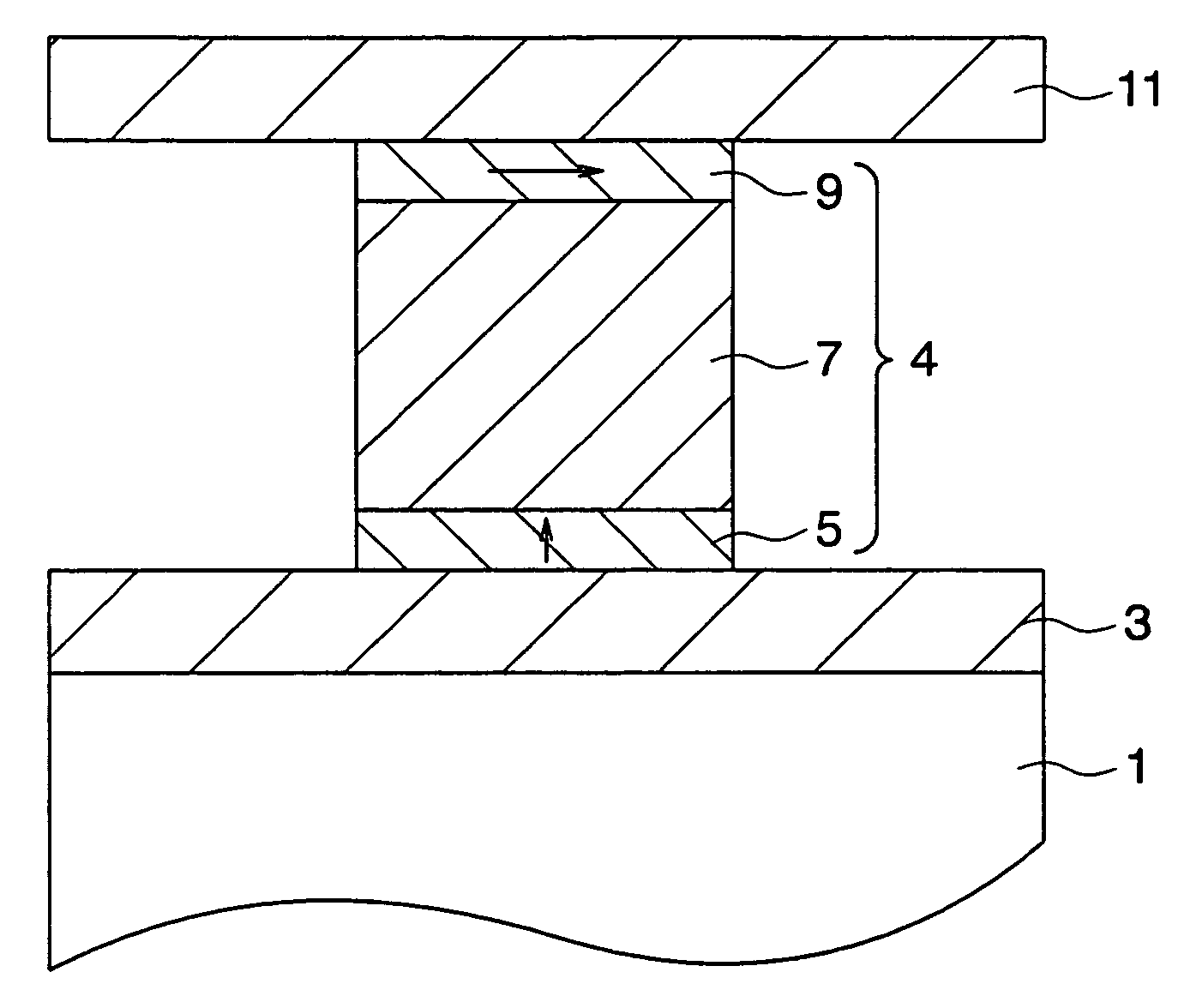

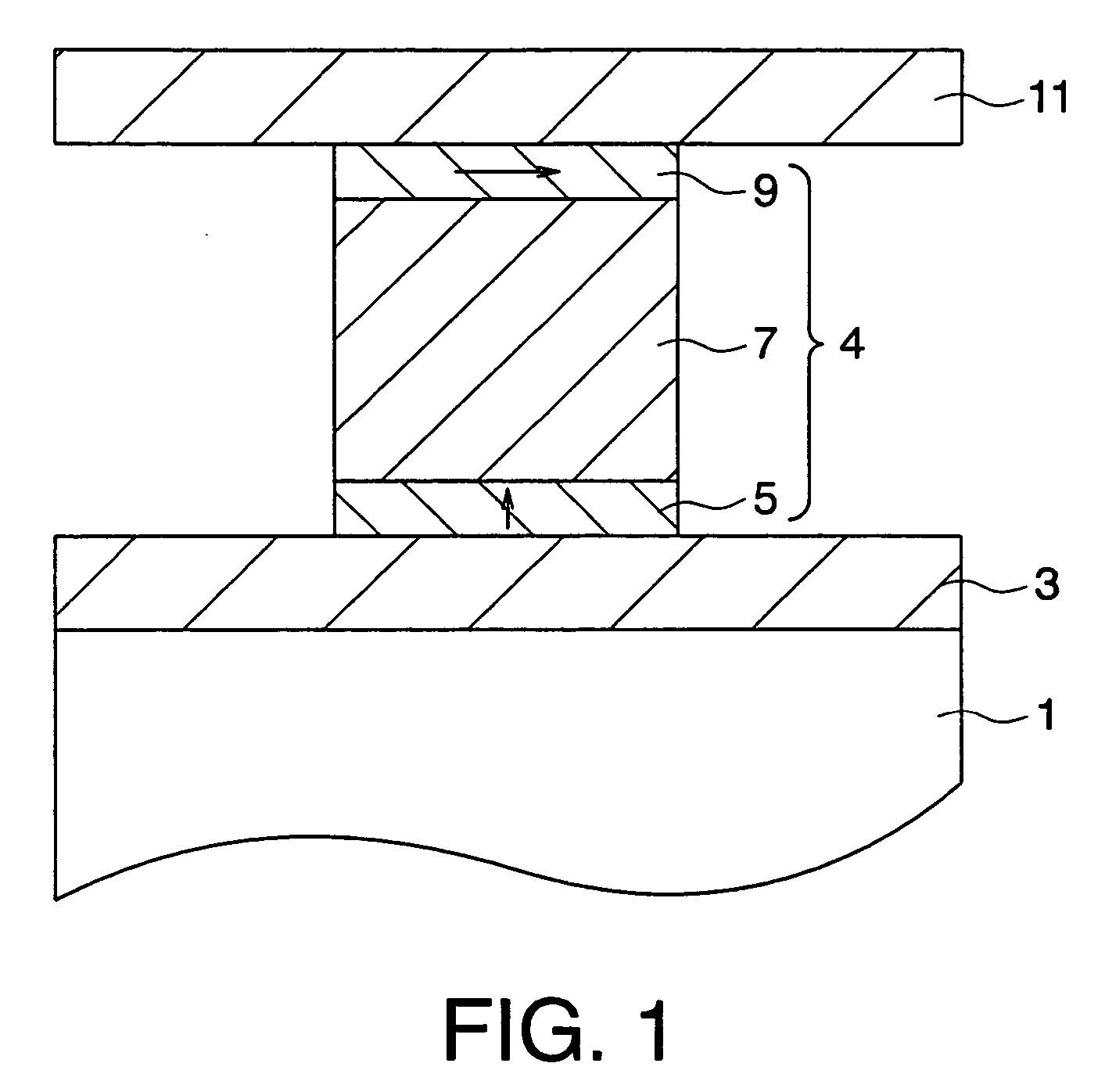

[0032] A resonant magneto-resistance effect element according to a first embodiment of the present invention is shown in FIG. 1. FIG. 1 is a sectional view showing the resonant magneto-resistance effect element according to the embodiment. The resonant magneto-resistance effect element according to the embodiment is provided on a substrate 1 with a lower electrode 3 also serving as a magnetic shield, a ferromagnetic layer 5 which is provided on the lower electrode 3 and whose magnetization direction is substantially perpendicular to a film plane, a non-magnetic layer 7 which is provided on the ferromagnetic layer 5, a ferromagnetic layer 9 which is provided on the non-magnetic layer 7 and whose magnetization direction is substantially perpendicular to the film plane, and an upper layer 11 which is provided on the ferromagnetic layer 9 and also serves as a magnetic shield. The ferromagnetic layer 5, the non-magnetic layer 7, and the ferromagnetic layer 9 have the same plan shape to c...

second embodiment

[0060] The first embodiment is directed to the resonant magneto-resistance effect element where the ferromagnetic layer 9 and the ferromagnetic layer 5 whose magnetization direction is substantially perpendicular to a film plane are each provided as a single layer, and the stacked film 4 formed via the non-magnetic layer is provided as a single piece.

[0061] A resonant magneto-resistance effect element according to the second embodiment has a plurality of the stacked films 4 according to the first embodiment which have been stacked. By stacking a plurality of the stacked films according to the first embodiment, spin fluctuation generated by the ferromagnetic layers whose magnetization directions are substantially parallel to the film planes sequentially induce resonances in the ferromagnetic layers whose magnetization directions are substantially perpendicular to the film plane, so that a further larger output voltage ΔV can be obtained. As shown in FIG. 4A, it is preferable that th...

third embodiment

[0063] Next, a resonant magneto-resistance effect element according to a third embodiment of the invention will be explained with reference to FIG. 9. A resonant magneto-resistance effect element of the embodiment has a constitution that a perpendicularly magnetizing bias film 22 is provided between the ferromagnetic layer 9 and the upper electrode 11 in the resonant magneto-resistance effect element according to the first or second embodiment.

[0064] In the first and second embodiments, change of external magnetic field applied within a plane of the ferromagnetic layer 5 is detected as change of a resonant frequency of the ferromagnetic layer 5 shown by Equation (7), but it is detected as change of a resonant frequency of the ferromagnetic layer 9 in the third embodiment. The smaller a difference between a shape anisotropy magnetic field 4πM and a crystalline anisotropy magnetic field HA perpendicular to the film plane, the larger change of a magnetic field frequency of a resonant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle of inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com