Treatment of iron contaminated liquids with an activated iron solids (AIS) process

a technology of activated iron solids and liquid treatment, which is applied in the direction of biological water/sewage treatment, quarries, separation processes, etc., can solve the problems of high cost of mine drainage treatment, and impact on social, recreational and commercial use. , to achieve the effect of high ferrous oxidation reaction ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

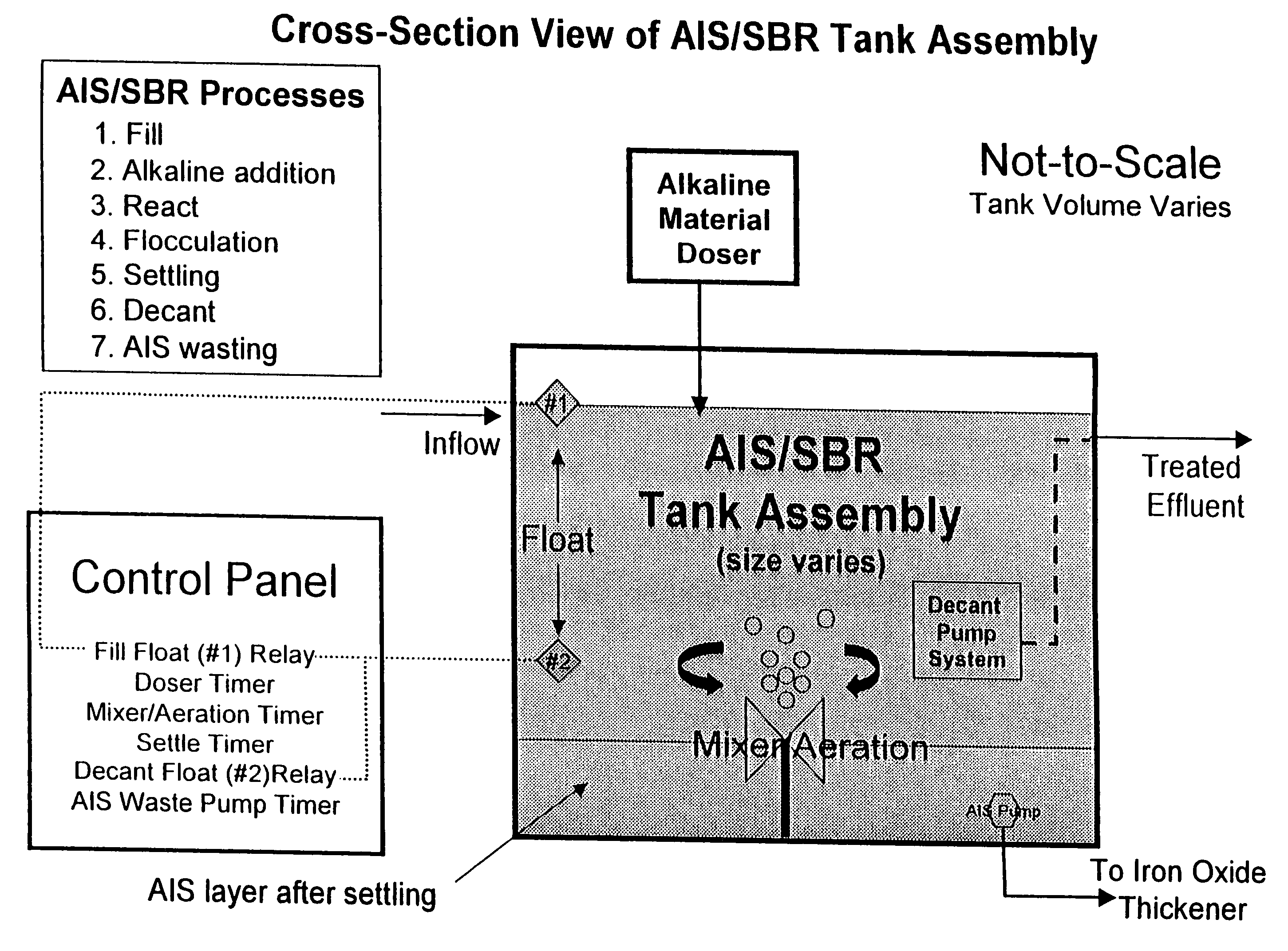

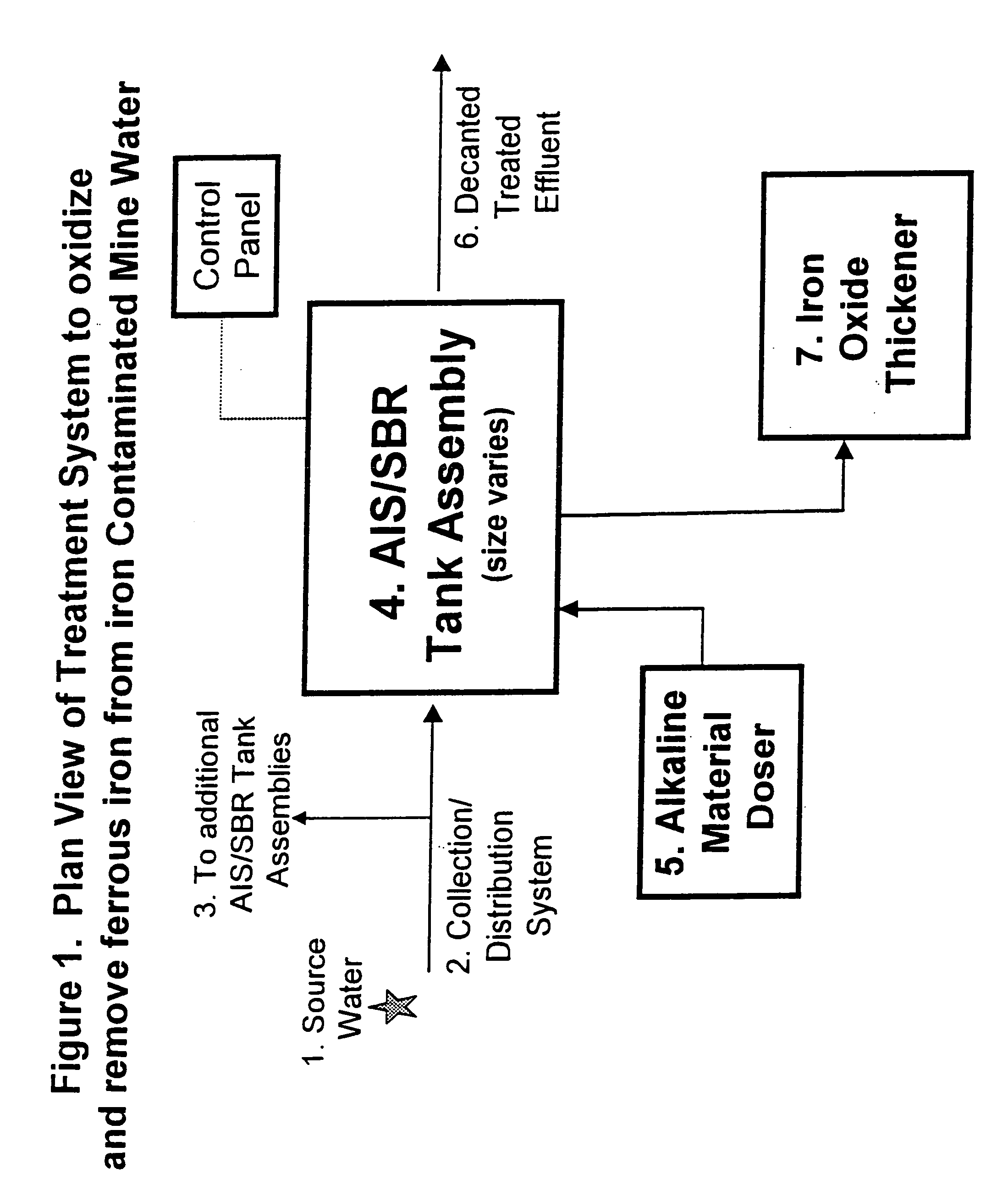

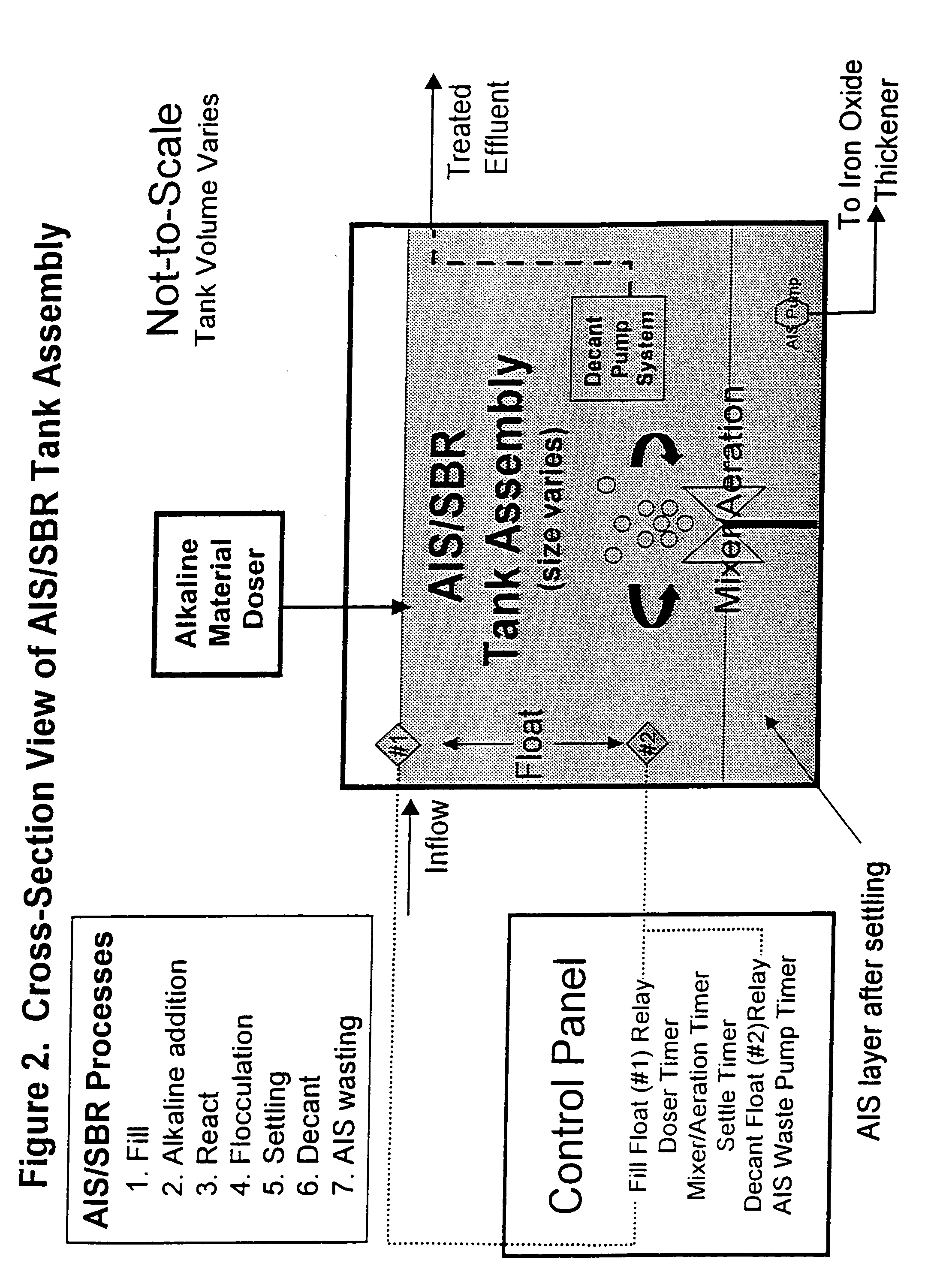

[0020]FIG. 1 is a plan view of the treatment system. An iron-contaminated water source (1) is directed into a least one AIS container assembly (4) or more preferably a plurality of AIS container assemblies. The means of directing the iron-contaminated water into at least one AIS container assembly may be by gravitational force or by pumping the iron-contaminated liquid into the AIS container assembly. When a plurality of AIS container assemblies are used in the treatment of iron-contaminated water, a means for collecting and distributing the iron-contaminated water, such as a header system or distribution tank assembly, precedes the AIS / container assembly (3).

[0021] The source of iron-contaminated fluid is directed through a first conduit (2) that is engaged with the inlet of the AIS container assembly (4) or a plurality of AIS container assemblies. Each AIS container assembly in a plurality of AIS container assemblies is identical as shown in FIGS. 2a and 2b, a cross-section view ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com