Device for the heating of a liquid

a liquid heating and liquid technology, applied in the field of liquid heating devices, can solve the problems of low thermal capacity and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

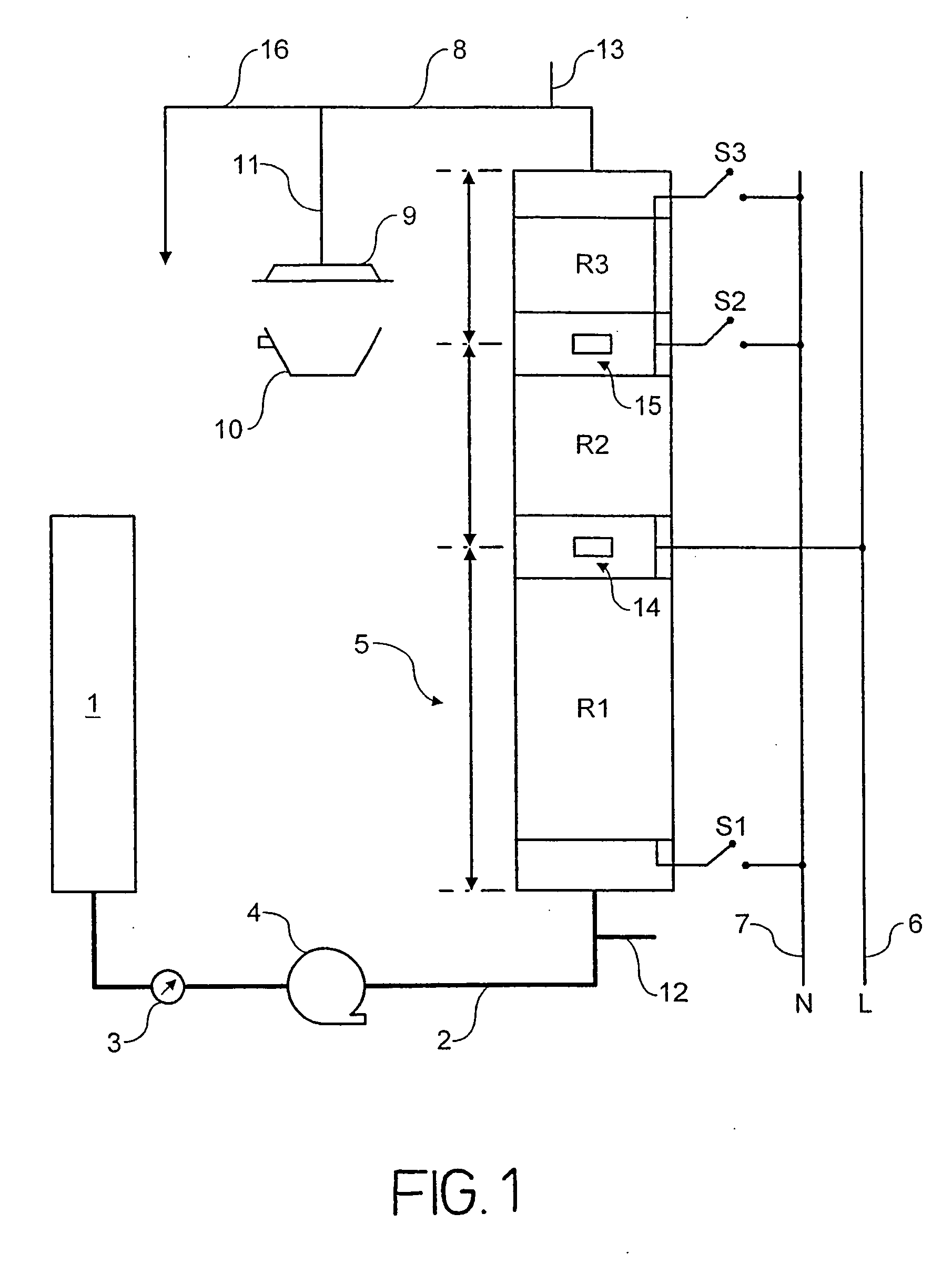

[0043] According to FIG. 1, the coffee machine comprises a cold water tank (1) connected through a pipe (2) to a flow-meter (3) and a pump (4) delivering the cold water to the device (5) for the heating of the water. The device (5) is in 3 parts: a first resistor R1 alone and both resistors R2 and R3, which are linked in serial. The connection of these resistors to the power occurs through (6, 7). At the exit of the device (5), the hot water flows through a conduit (8) and arrives through (11) on a cartridge (9) containing roast and ground coffee. This cartridge is a sealed cartridge opening under pressure according to the EP patent No. 512'468. The ready to drink coffee flows in a cup (10). The coffee machine comprises further a cold water temperature sensor (12), a hot water temperature sensor (13) and also sensors (14) and (15) disposed between R1, R2 respectively R2, R3. It is also possible according to the invention to have at the exit of the heating device a conduit (16) for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com