Inhaler

a technology of inhaler and powder, which is applied in the field of dry powder inhaler, can solve the problems of uncontrollable shearing force, unacceptable, and unsuitable parts of the dose, and achieve the effect of reducing retention and high air speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

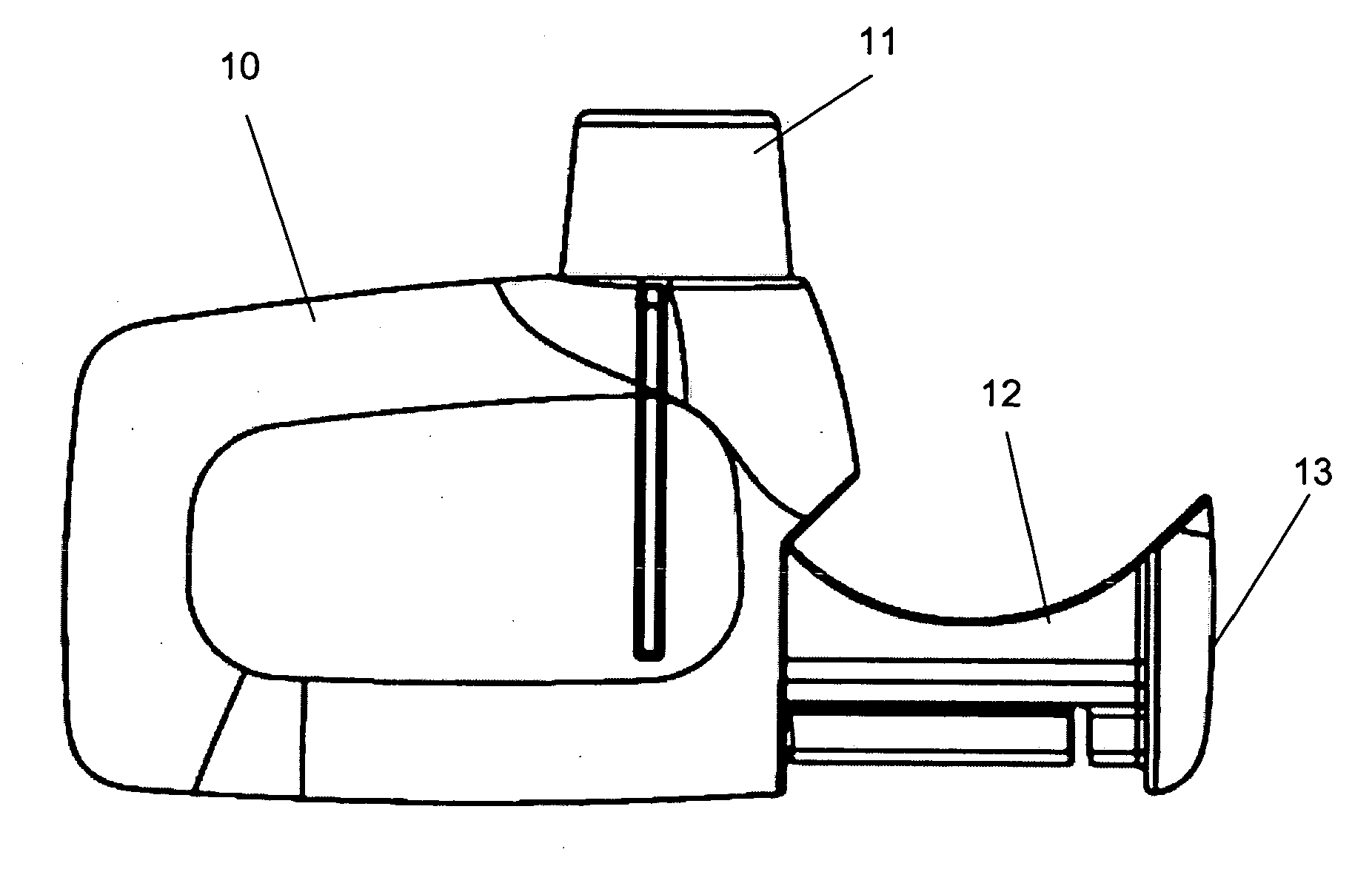

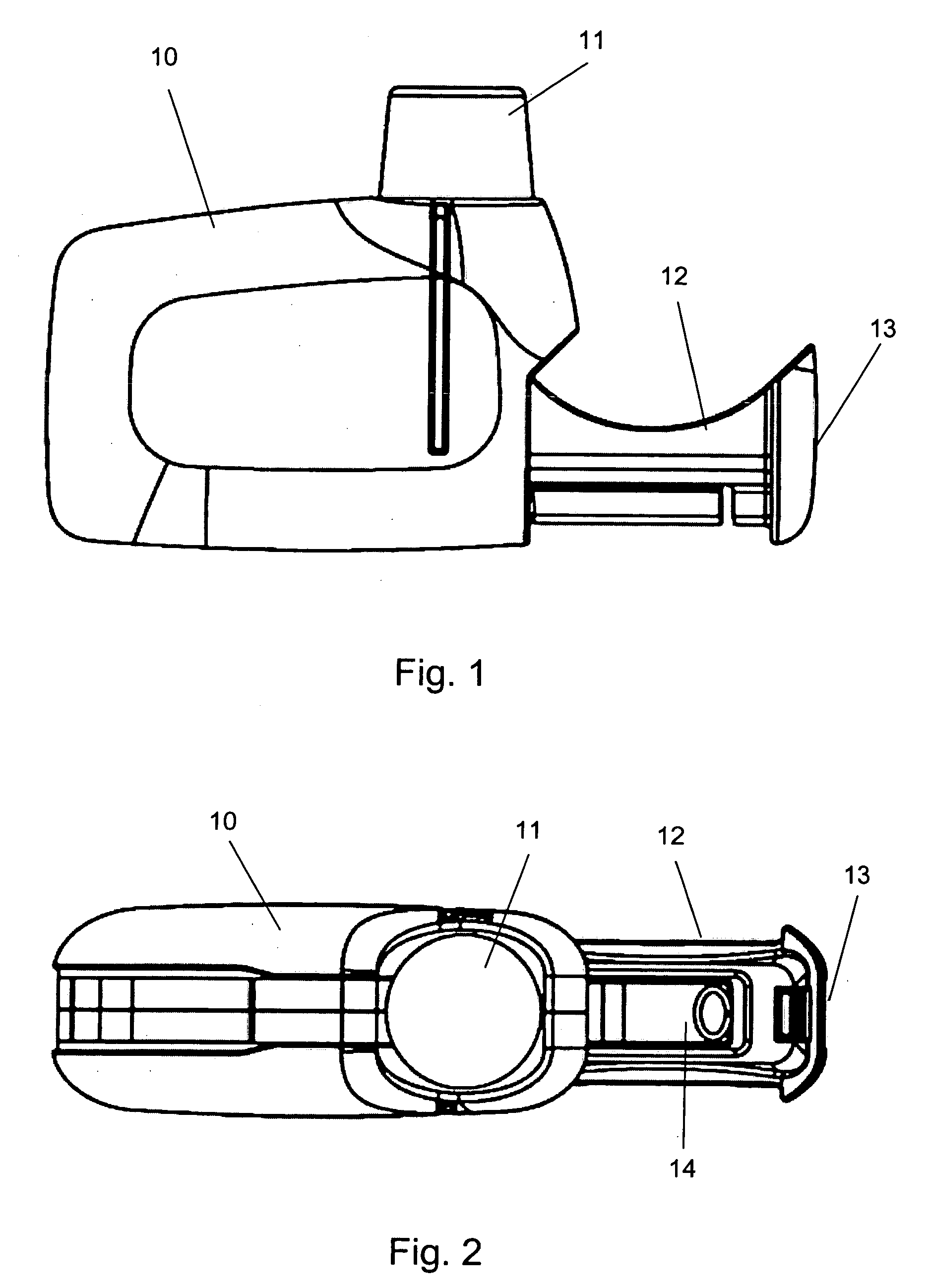

[0029] The present invention discloses a novel type of manually operated, dry powder inhaler device (DPI) adapted for accepting a dose container enclosing a metered dry powder dose. The disclosed inhaler device is preferably a single dose inhaler relying on the power of a user for delivering dry powder doses of medicaments. The inhaler device can have a movable slide, which is intended to be loaded with a replaceable dose container by a user. The user inserts the dose container into the inhaler body, for example by pushing the slide into the body by hand force. When the dose in the dose container has been delivered by the DPI, the slide is brought out of the inhaler body, at any convenient point in time. The user then can remove the spent container and can, if desired, push the now empty slide again into the inhaler body or, for example, load a new dose container into the slide in preparation of a new dose delivery. In this manner a new container with a new dose may be administered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com