Liquid crystal display device manufacturing method and liquid crystal display device manufacturing system

a liquid crystal display device and manufacturing method technology, applied in the direction of ceramic shaping apparatus, instruments, optics, etc., can solve the problems of lowering the discharge precision of liquid crystal under such conditions, trouble on the display, and lowering the precision of liquid crystal discharge. , to achieve the effect of reducing the error of liquid crystal amount in the excellent display of liquid crystal display device, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0028] (First Embodiment)

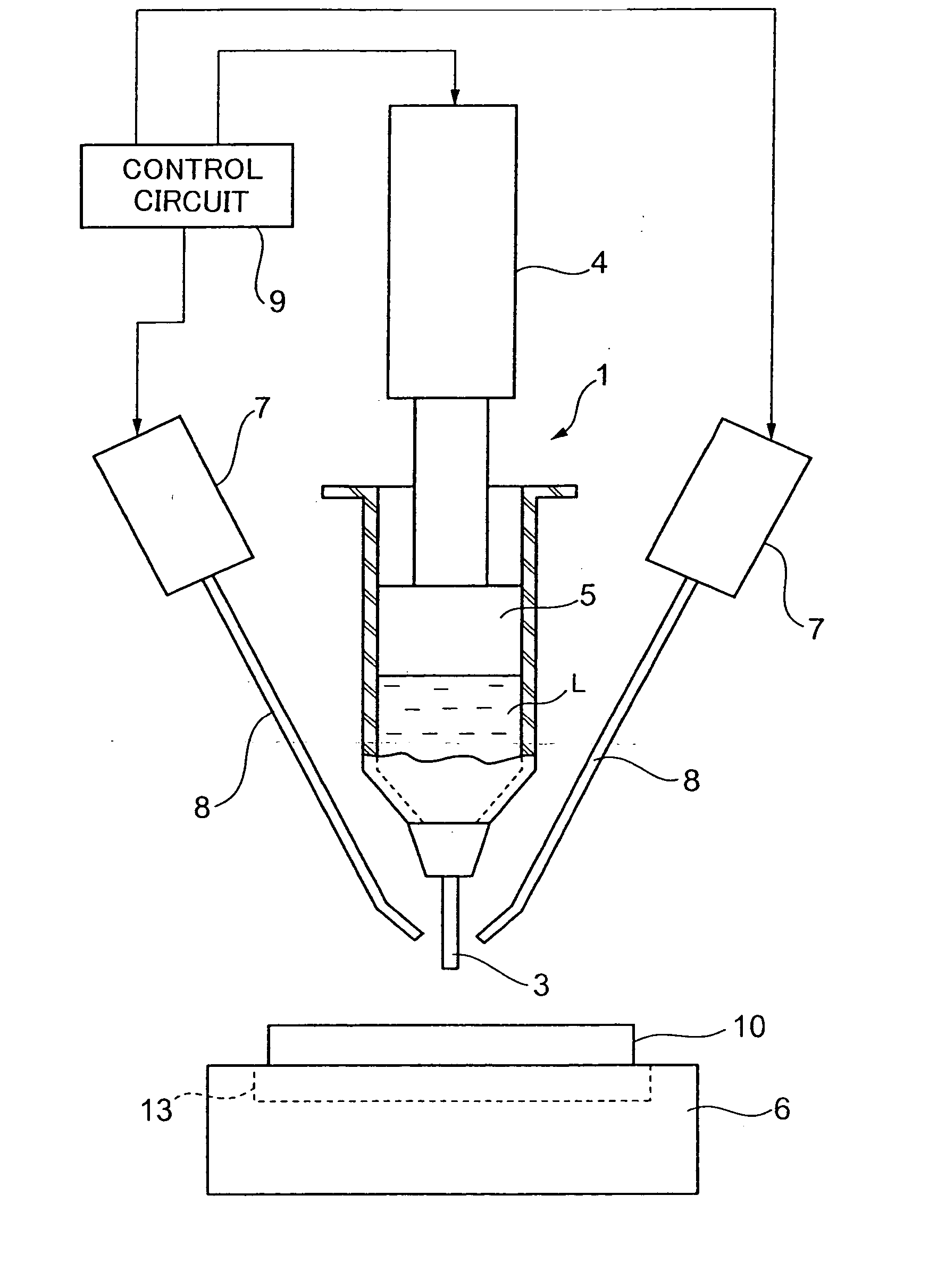

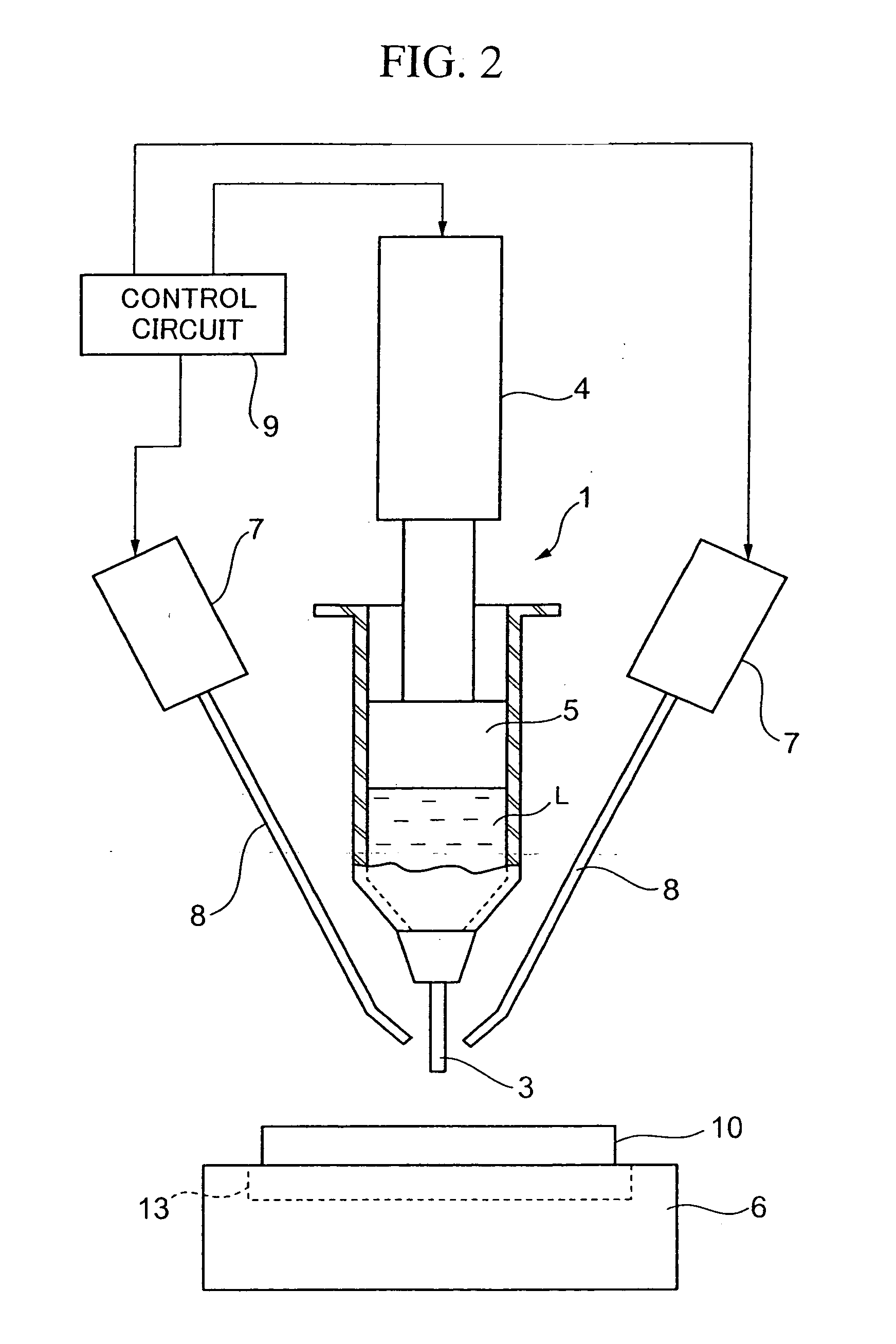

[0029]FIG. 2 is a view showing a configuration of a liquid crystal supplying equipment employed to manufacture a liquid crystal display device according to a first embodiment of the present invention.

[0030] In FIG. 2, a hollow liquid crystal supply needle 3 is provided to the bottom end of a liquid crystal supply syringe 1 to drop down the liquid crystal L in the syringe 1 on a first substrate 10. A plunger 5 that is connected to a driving source 4 is inserted into the inside of the syringe 1, and the liquid crystal L is pushed out from the top end of the liquid crystal supply needle 3 by descending the plunger 5. The plunger 5 is mechanically moved vertically by the driving source 4.

[0031] A loading table 6 on which the first substrate 10 is loaded is arranged movably under the syringe 1. Also, the syringe 1 is arranged at a height, that provides an interval of 10 to 20 mm, for example, between the loading table 6 and the liquid crystal supply needle 3, s...

second embodiment

[0056] (Second Embodiment)

[0057] The plunger system syringe is employed as the liquid crystal supplying equipment shown in FIG. 2, but an air system syringe 15 shown in FIG. 6 may be employed. In the case of this air system syringe, the air supply needles 8 may also be arranged around the liquid crystal supply needle. In this air system syringe 15, the liquid crystal can be dropped down from a liquid crystal supply needle 17 provided to the top end of the syringe 15 by pressuring the liquid crystal filled in the syringe 15 from the upper side by the air pressure.

[0058] According to the air system plunger, even if the same air pressure is applied to the inside of the syringe 15, a total amount of the liquid crystal dropped onto the first substrate 10 is varied because of a residual amount of the liquid crystal in the syringe 15, as shown in Table 3. Table 3 shows the cases where an amount of the liquid crystal in the syringe 15 is set to 15 g (large), 7 g (middle), and 2.5 g (small)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| specific gravity | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com