Liquid crystal display device

a liquid crystal display and display device technology, applied in the direction of optics, instruments, printed circuit aspects, etc., can solve the problems of large power consumption, large drive circuit, and longitudinal smear (crosstalk) that is produced in a direction along the drain line, and achieves low aperture efficiency, high aperture efficiency, and aperture efficiency over 50%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

>

[0044] Hereinafter, an embodiment where the present invention is applied to an active matrix system color liquid crystal display device will be explained. In the drawings, elements which have the same function are indicated by the same symbols and a repeated explanation thereof is omitted.

>

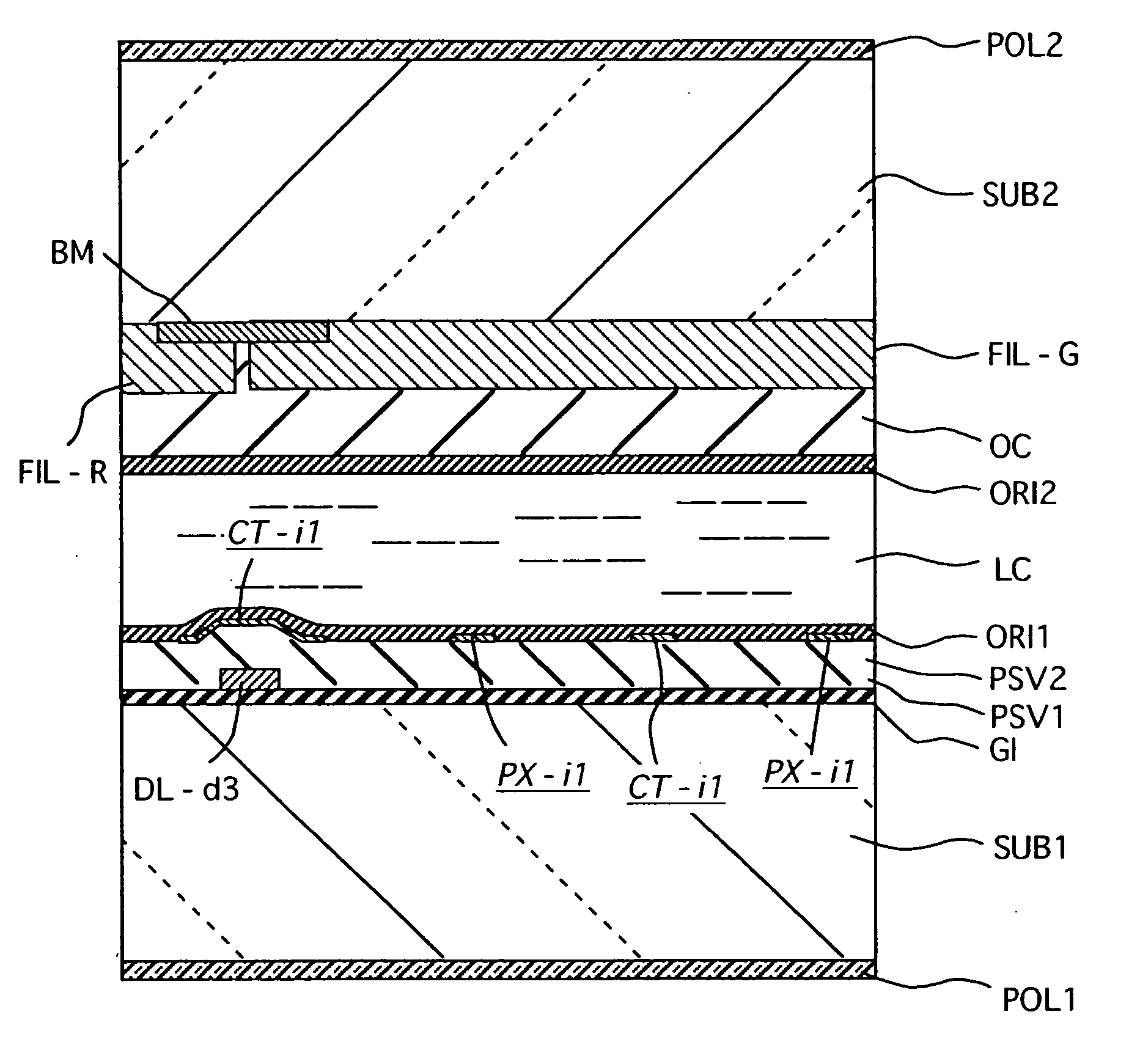

[0045]FIG. 1 is a plan view showing one pixel and its periphery of the active matrix system color liquid crystal display device of the present invention.

[0046] As shown in FIG. 1, each pixel is disposed in an intersect region (region enclosed by four signal lines) defined by a gate line (scanning signal line or a horizontal signal line) GL, a counter line (counter voltage signal line) CL, and two neighboring drain lines (image signal lines or vertical signal lines) DL. Each pixel includes a thin film transistor TFT, a storage capacitance Cstg, a pixel electrode PX (called a pixel electrode in this embodiment and acts as a display electrode) and a counter electrode CT (called a counter electrode...

embodiment 2

[0146] The present embodiment is the same as the embodiment 1 except for the following conditions. FIG. 20 is a plan view of the pixel and FIG. 21, is a cross-sectional view of a comb-shaped electrode portion.

>

[0147] In this embodiment, the pixel electrode PX is comprised of a source electrode SD1, a drain electrode SD2 and a conductive film d3 on the same layer as the drain electrode SD2. Furthermore, the pixel electrode PX is integrally formed with the source electrode SD1.

[0148] According to this embodiment, in addition to the effects of the first embodiment, a contact failure with the pixel electrode PX can be avoided, although the transmissivity is sacrificed. Furthermore, since the pixel electrode PX is covered with an insulating film (the passivation layer PSV1), when an orientation failure occurs, the possibility that a direct current will flow through the liquid crystal is lowered, thus eliminating a deterioration and the like of the liquid crystal, so that the reliabilit...

embodiment 3

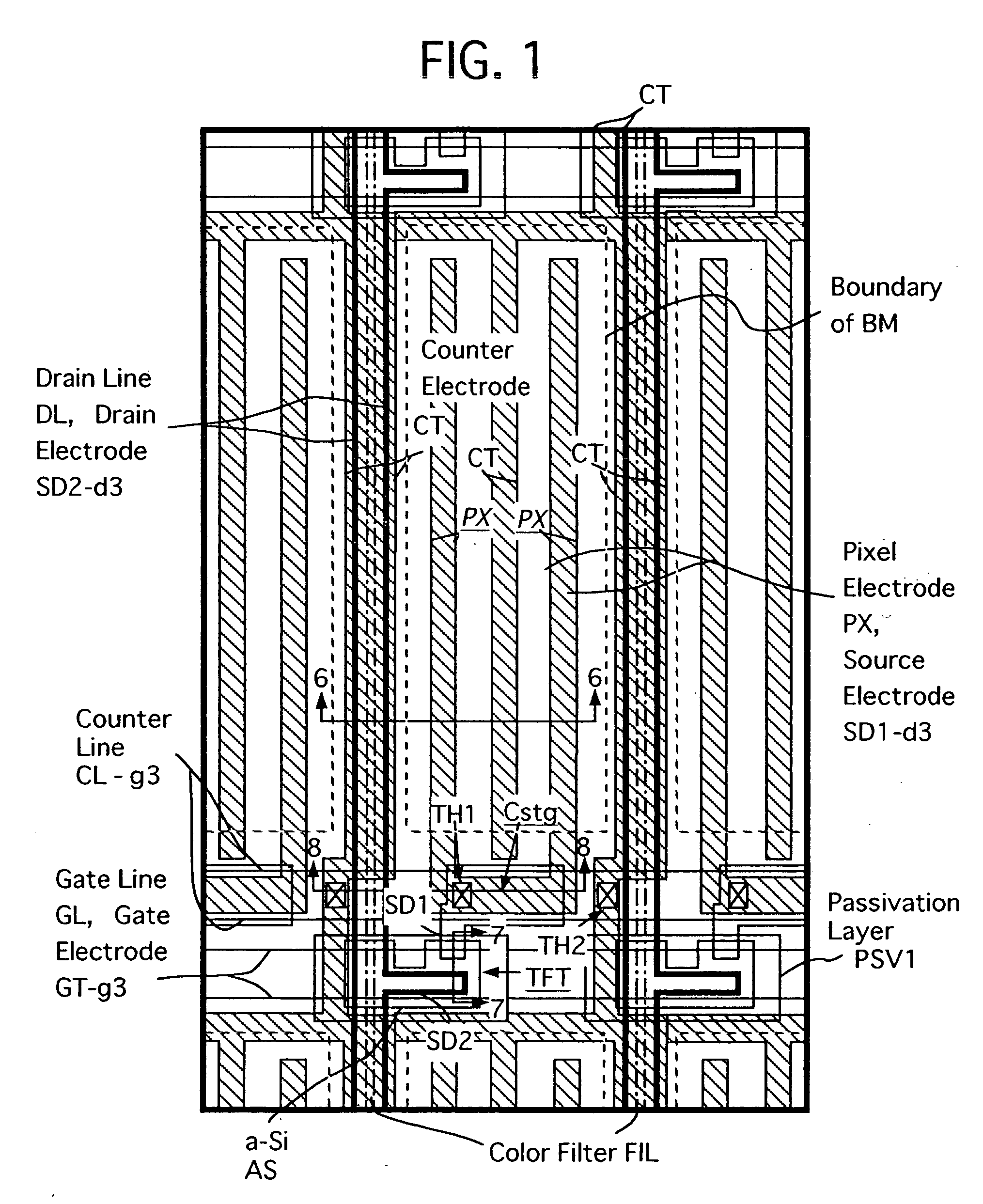

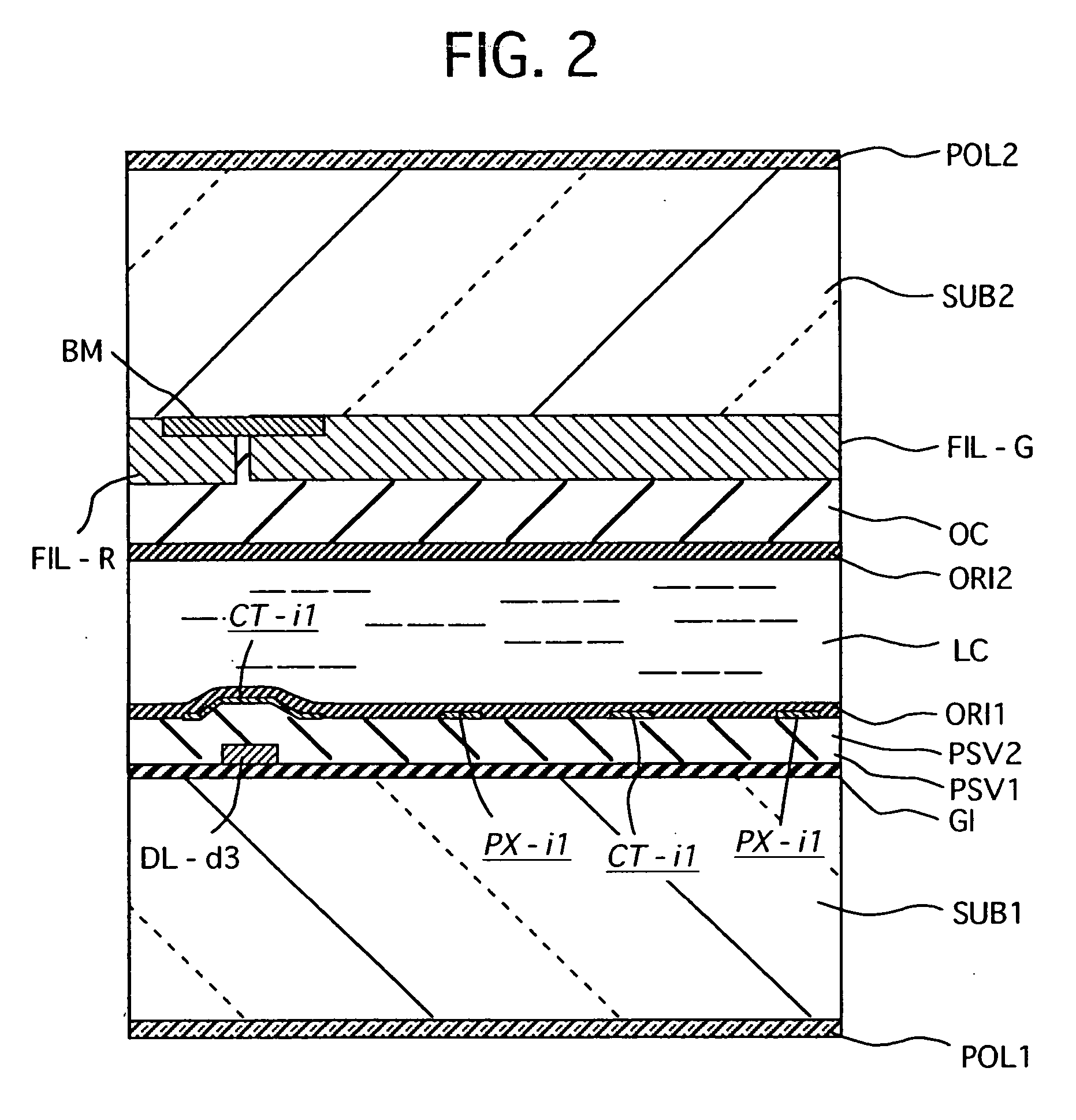

[0149] The present embodiment is the same as the embodiment 1 except for the following conditions. FIG. 22 is a cross-sectional view of the pixel of this embodiment.

[0150]1, Organic Passivation Layer PSV2>>

[0151] In this embodiment, the passivation layer PSV1 and the organic passivation layer PSV2 are collectively removed, such that the external connecting terminals DTM, GTM are exposed. Accordingly, in contrast to the embodiment 1, the passivation layer PSV1 is formed on most of the pixel. Furthermore, in the pixel portion, for assuring an electric connection between the counter line CL and the counter electrode CT, which will be explained later, and an electric connection between the source electrode SD2 and the pixel electrode PX, through holes TH2 and TH1 are formed. At the through hole TH2, the organic passivation layer PSV2, the passivation layer PSV1 and the insulating film GI are collectively subjected to working and a hole which reaches the layer g3 is formed, while at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific dielectric constant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com