Laser cutting of stents and other medical devices

a technology of stents and cutting blades, applied in the direction of manufacturing tools, blood vessels, other domestic objects, etc., can solve the problem of not being able to cut as effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] While this invention may be embodied in many different forms, there are shown in the drawings and described in detail herein specific embodiments of the invention. The present disclosure is an exemplification of the principles of the invention and is not intended to limit the invention to the particular embodiments illustrated.

[0033] For the purposes of this disclosure, like reference numerals in the figures shall refer to like features unless otherwise indicated.

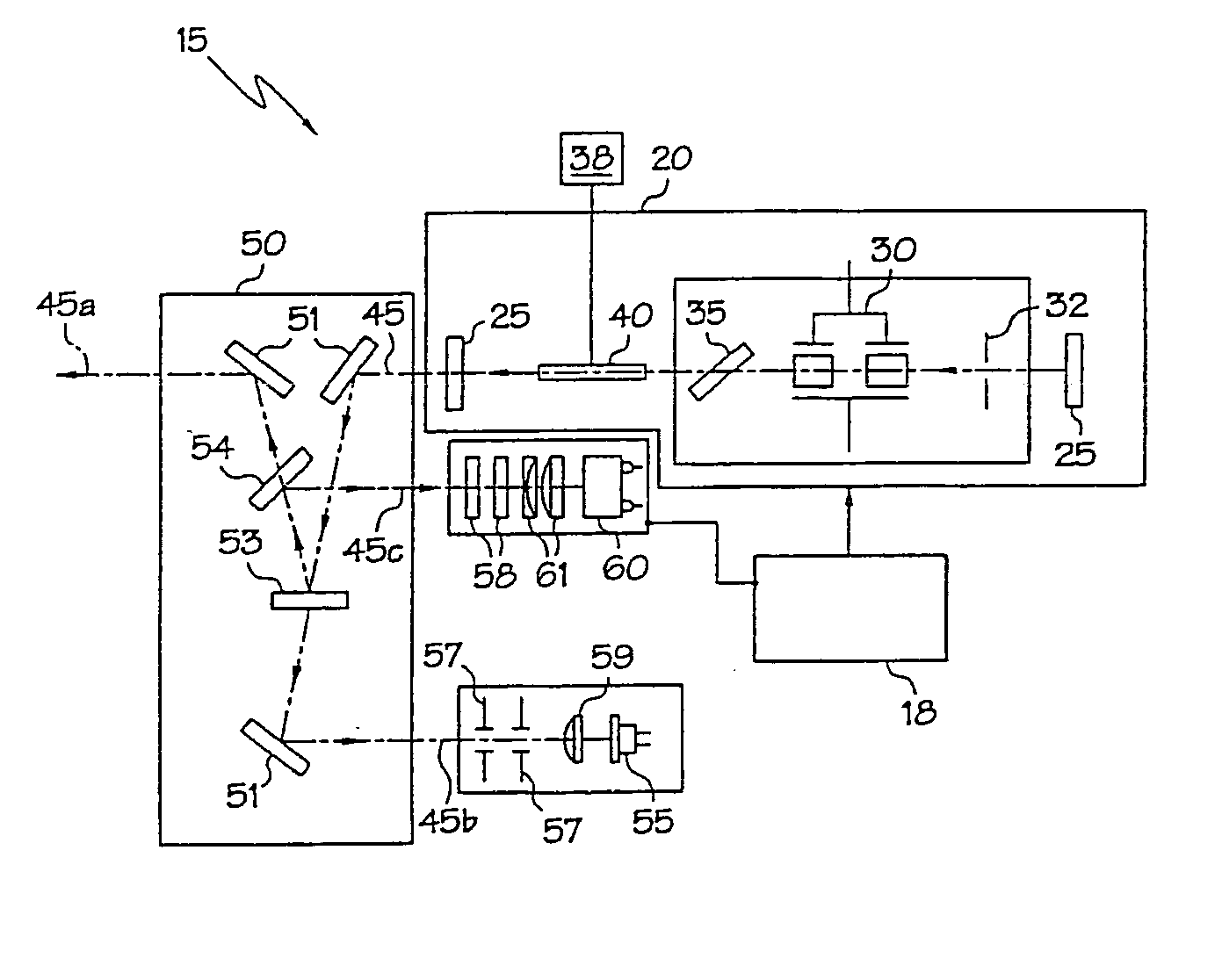

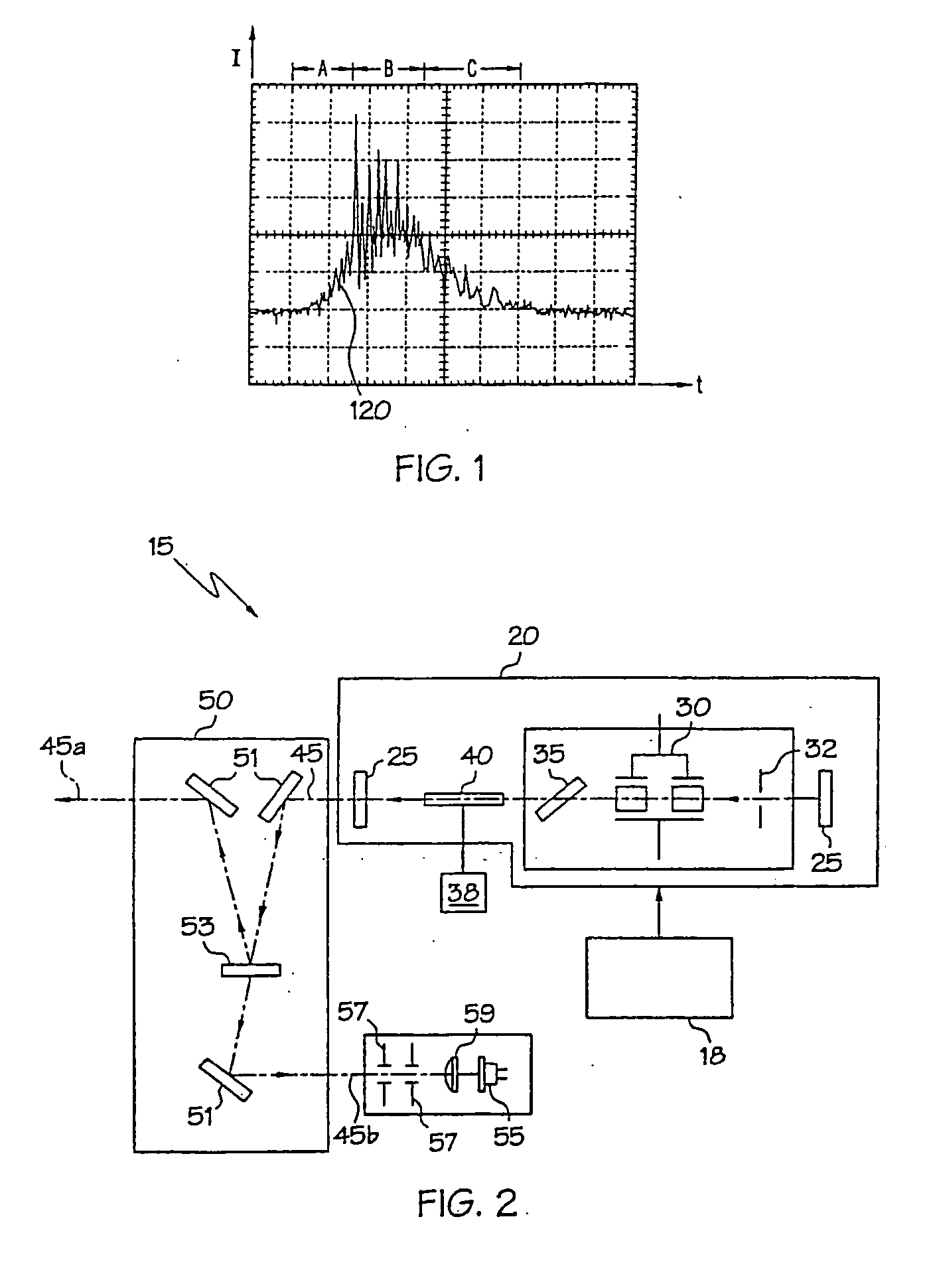

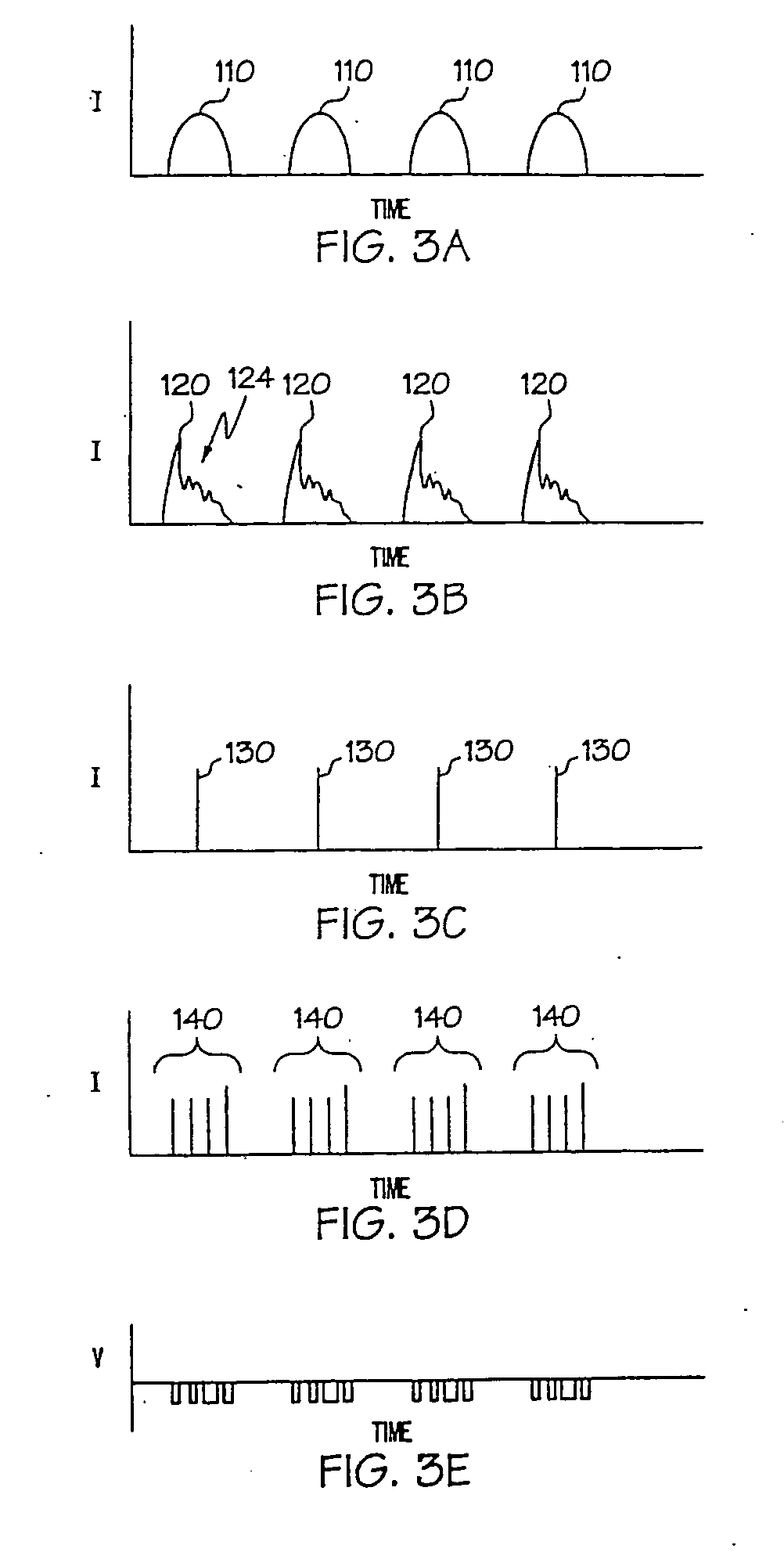

[0034] The present invention, in some of its embodiments, provides methods for manipulating laser beams for cutting stent preforms, stents and other workpieces. The invention also provides for laser systems for generating the laser beams used in the practice of the inventive methods.

[0035] In one embodiment, the present invention is directed to a method of processing a stent preform using a laser beam. The stent preform may be in the form of a tube, a sheet or any other shape of material into which a stent design ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength range | aaaaa | aaaaa |

| wavelength range | aaaaa | aaaaa |

| polymeric | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com