[0018] According to the present invention, the affinity for the liquid of the first surface area including the optical element disposed at the tip of the projection optical system is made higher than that of the second surface area disposed therearound. Accordingly, the liquid is stably arranged on the

optical path for the exposure

light beam owing to the first surface area. Further, the liquid is not spread with the

wetting to the surroundings owing to the second surface area, and thus does not outflow to the outside. Therefore, the liquid can be stably arranged on the

optical path for the exposure

light beam even in the case of the

full field exposure in which the substrate stands still with respect to the exposure

light beam during the exposure as well as in the case of the scanning type exposure in which the substrate is moved with respect to the exposure light beam during the exposure.

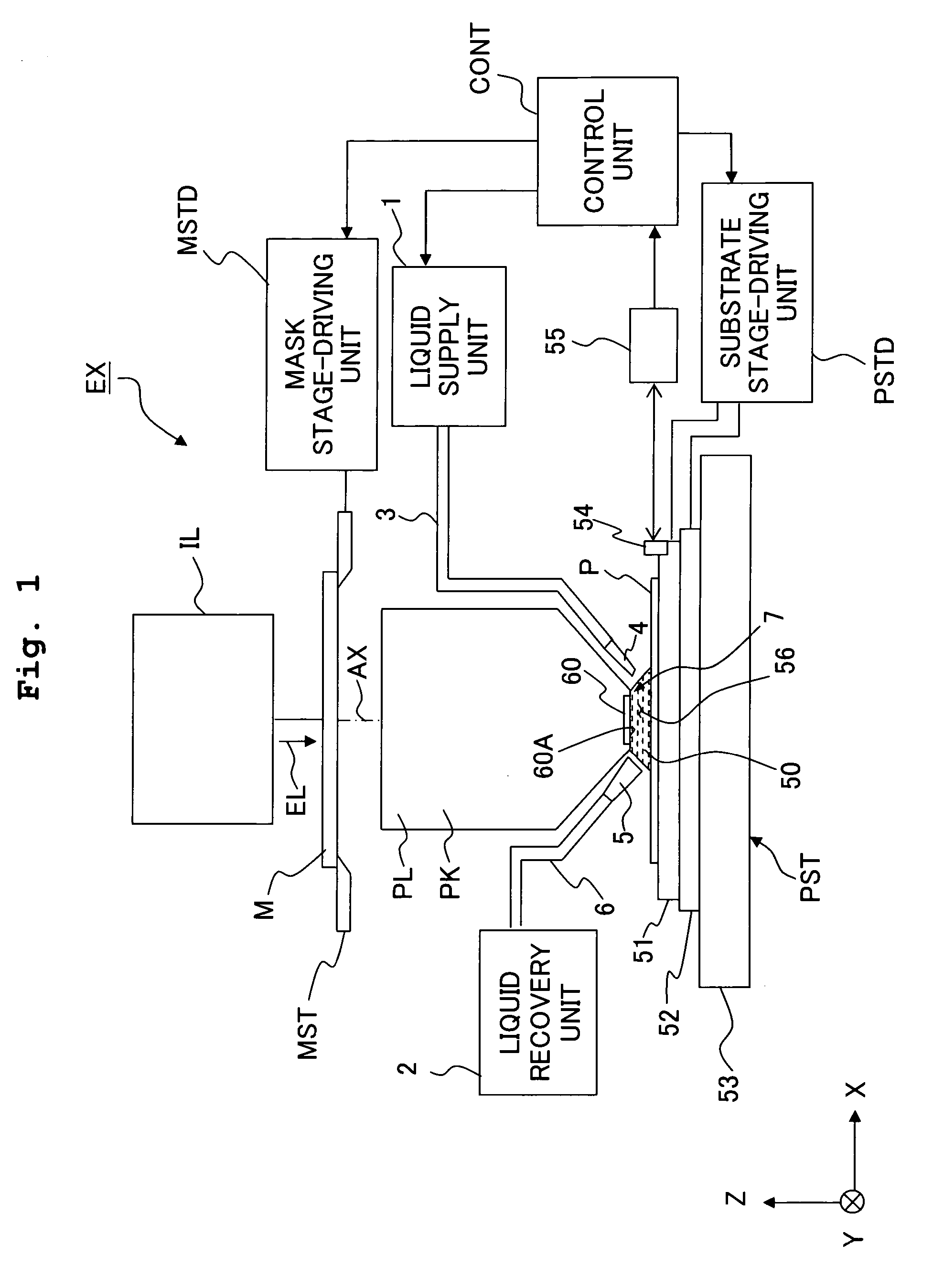

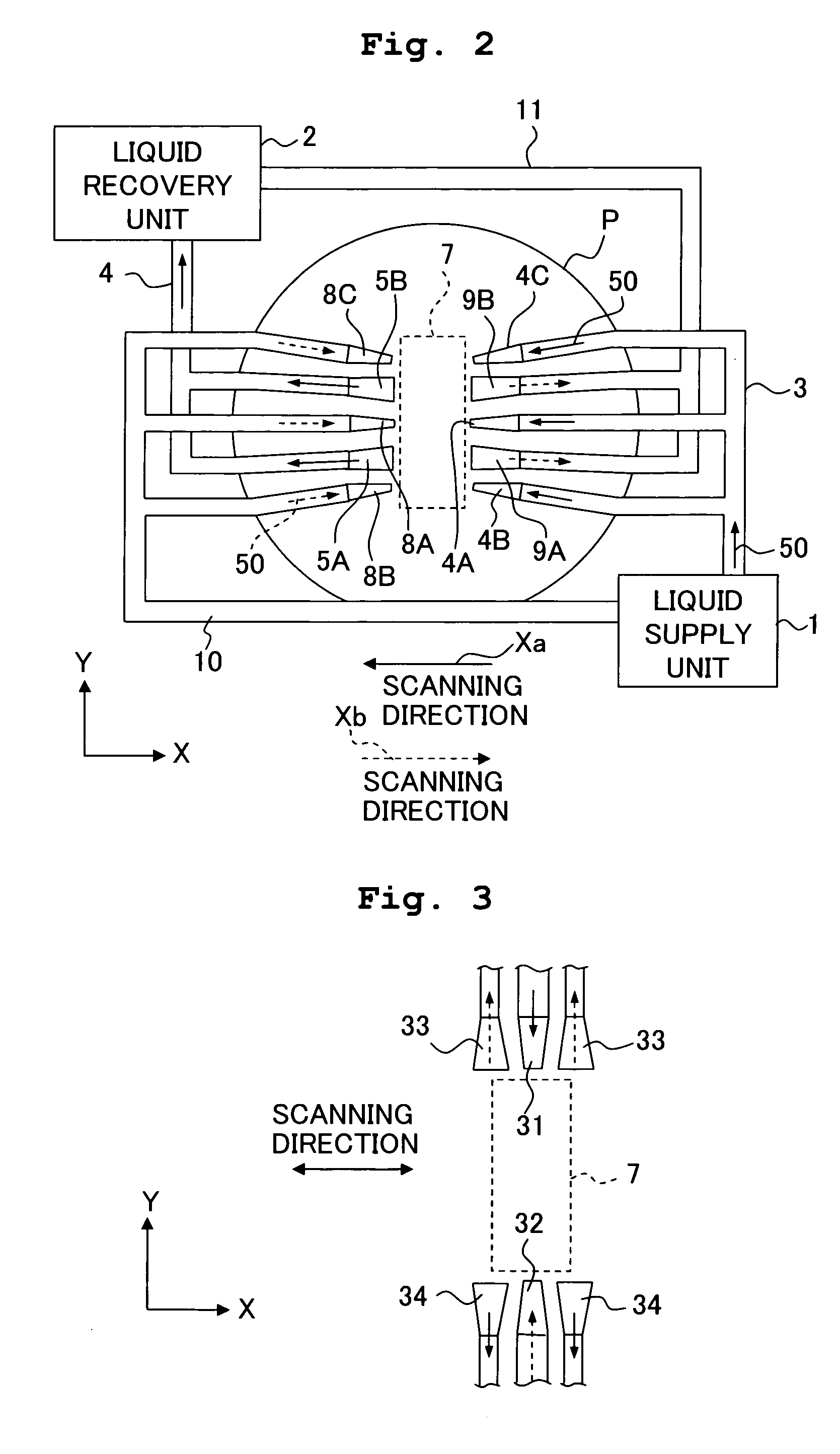

[0023] According to the present invention, the condition, under which the liquid is maintained in at least the part of the space between the projection optical system (PL) and the substrate (P), is set so that the

conditional expression described above is satisfied. Accordingly, no turbulence arises in the liquid. Therefore, it is possible to suppress any inconvenience which would be otherwise caused, for example, such that the pattern image to be projected onto the substrate is deteriorated due to the turbulence of the liquid.

[0028] According to the present invention, the liquid immersion state is controlled by various methods, and thus the liquid flows while forming the laminar flow in parallel to the scanning direction of the substrate during the exposure. Therefore, it is possible to avoid the deterioration of the pattern image to be projected onto the substrate. Further, no unnecessary vibration is generated, for example, in the projection optical system which makes contact with the liquid as well as in the

wafer and the substrate stage which holds the

wafer. The flow of the liquid can be made into the laminar flow, for example, by controlling the amount of supply (

recovery) of the liquid by the liquid immersion unit, adjusting the structure of the liquid supply

nozzle of the liquid immersion unit, and / or adjusting the velocity when the substrate is moved during the exposure.

[0034] According to the present invention, the liquid immersion unit is controlled such that the liquid is not supplied during the exposure for the substrate. Accordingly, the photosensitive material, which has been applied onto the substrate, is not damaged. It is possible to avoid the deterioration of the pattern to be formed on the substrate. Further, the positional relationship between the projection optical system and the substrate can be stably maintained in a desired state.

[0039] According to the present invention, the surface treatment is applied to the surface of the substrate depending on the affinity for the liquid before performing the liquid immersion exposure. Accordingly, the liquid can be maintained on the substrate in a state preferable for the liquid immersion exposure. For example, if the affinity for the liquid is too low, any inconvenience arises, for example, such that the liquid is exfoliated from the surface of the substrate, and / or any bubble is generated. On the other hand, if the affinity for the liquid is too high, any inconvenience arises in some cases, for example, such that the liquid is spread excessively while causing

wetting on the substrate. On the contrary, when the appropriate surface treatment is applied to the

substrate surface in consideration of the affinity for the liquid as in the exposure method of the present invention, then the liquid can be maintained in a desired state on the substrate, and it is possible to appropriately perform the

recovery and the removal of the liquid on the substrate.

Login to View More

Login to View More