Semiconductor device having porous structure

a technology of semiconductor devices and porous structures, which is applied in the direction of semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of difficult to achieve, difficult to achieve, and difficult to achieve, and achieve excellent mechanical properties. , the effect of excellent applicability to the dual damascene process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] As described above, in an aspect, the present invention provides a method for manufacturing a semiconductor device, which method can be performed using any suitable plasma CVD chambers which can be operated as one operation system. This is an advantage of the present invention. However, chambers specifically designed for respective steps can be used. The method is suitable for any Damascene process, especially the Dual Damascene process which is described in U.S. Pat. No. 6,440,838 or U.S. Pat. No. 6,440,861, for example, the disclosure of which is incorporated herein by reference in its entirety.

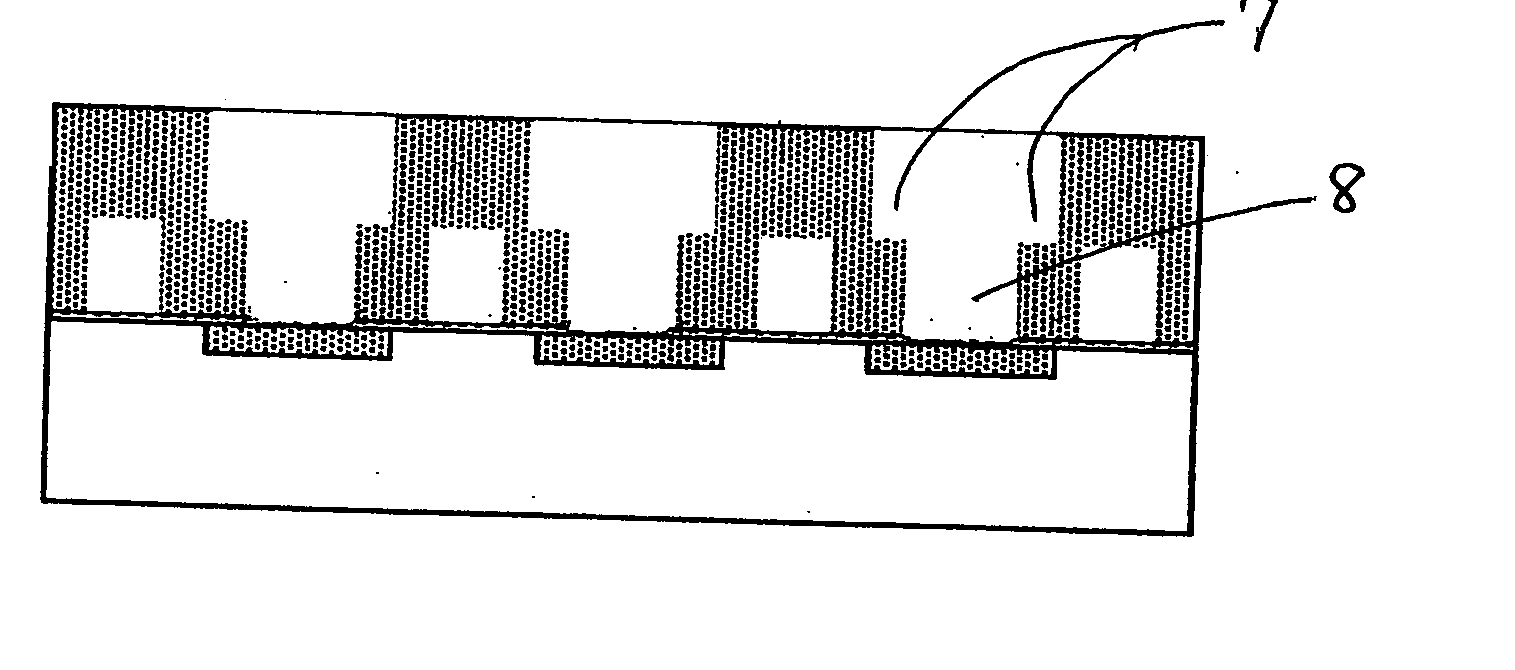

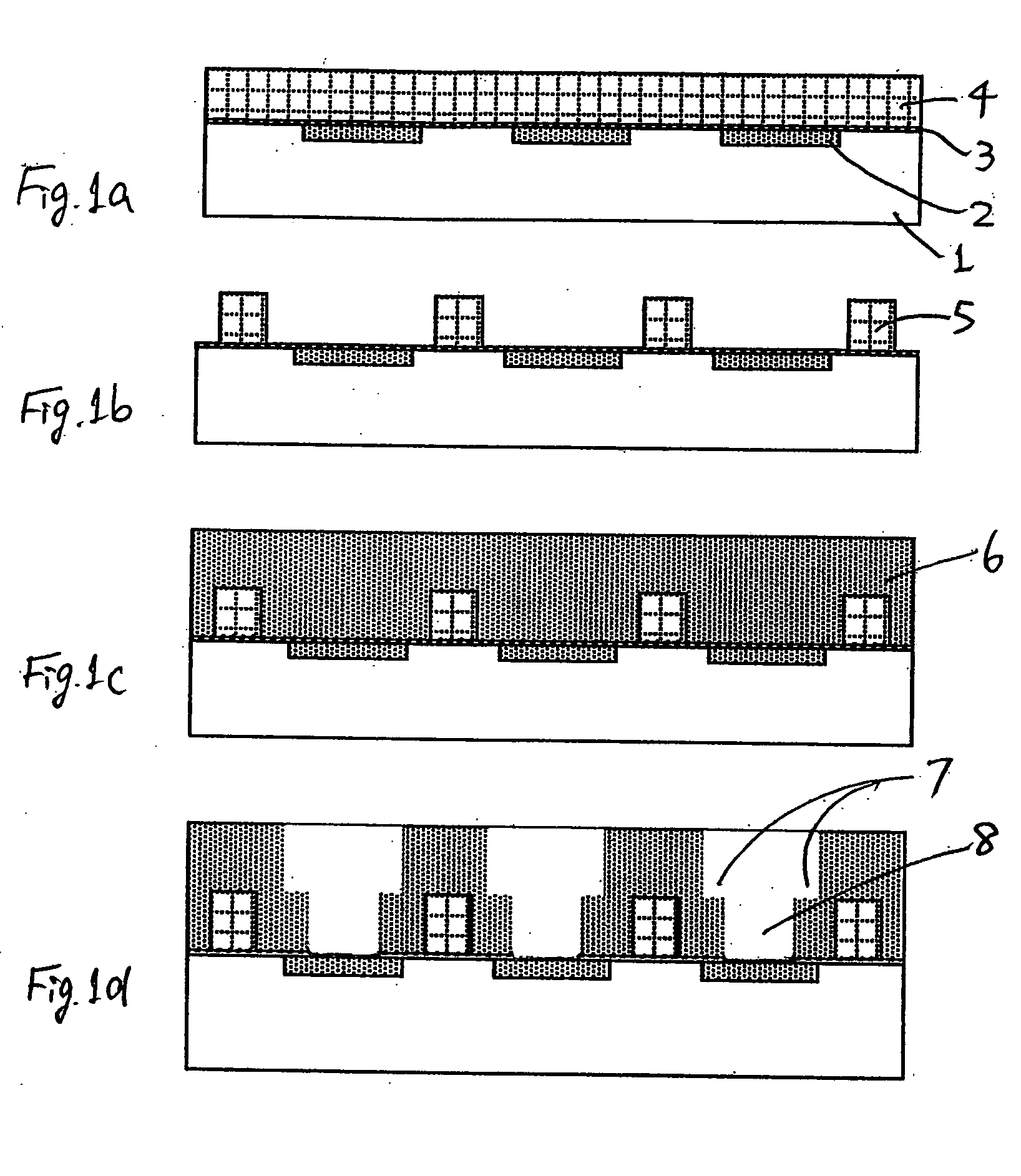

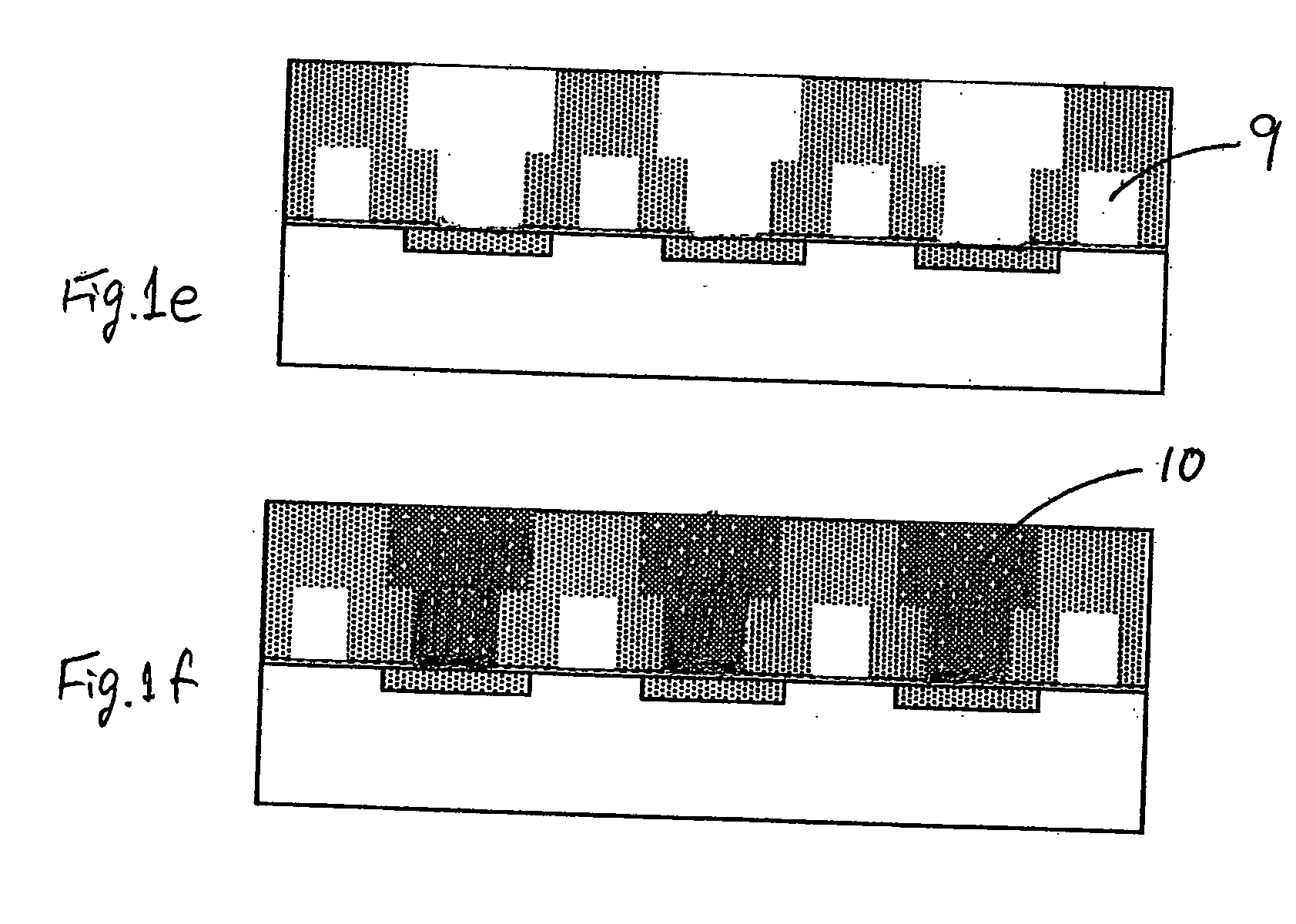

[0028] An embodiment comprises the steps of: (i) depositing a sacrificial layer on a substrate having a circuit formed thereon; (ii) etching the sacrificial layer except for a portion where air gaps are to be formed; (Add the comment written above for etch stop layer option) (iii) depositing a low-dielectric layer over the substrate until the portion for air gaps is entirely enclose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com