Light emitting device with an omnidirectional photonic crystal

a light emitting device and photonic crystal technology, applied in the direction of solid-state devices, lasers, semiconductor lasers, etc., can solve the problems of significant increase in manufacturing costs and significant decrease in production yield, and achieve the effect of enhancing radiation extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

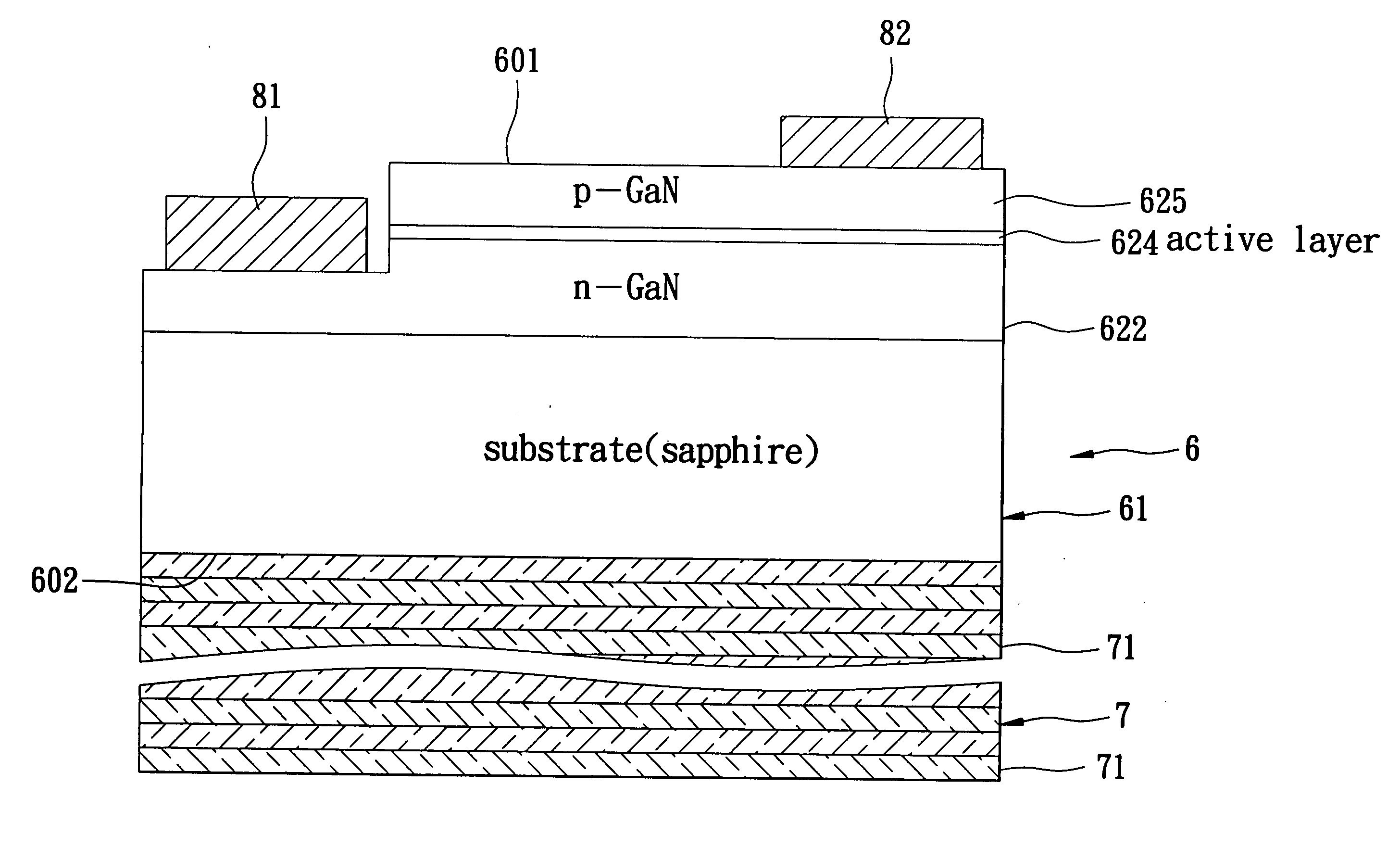

[0041] In this Example, the first and second semiconductor layers 622, 625 of the light emitting diode 6 are made from GaN material. The substrate 61 is made from sapphire. The light emitting diode 6 is capable of emitting a UV light radiation having a wavelength range ranging from 300 nm to 420 nm. The omnidirectional photonic crystal 7 is formed on the outer surface of the substrate 61 through e-beam evaporation techniques, and includes fourteen dielectric units 71, each of which includes the first and second dielectric layers 711, 712 which are respectively made from TiO2 and SiO2 and which respectively have refractive indices of 2.6 and 1.8, i.e., a refractive index difference of 1.12. The lattice constant a is equal to 110 nm. The thickness (d1) of the first dielectric layer 711 is equal to 0.42a.

[0042]FIG. 6 shows the presence of an omnidirectional photonic band gap in a frequency range between two dash lines in FIG. 6, i.e., between 0.273c / a and 0.3c / a, in the dispersion rel...

example 2

[0047] The light emitting device of this Example differs from the previous Example in that the light emitting diode 6 is capable of emitting a blue light radiation having a wavelength range ranging from 420 nm to 480 nm, that the thickness (d1) of the first dielectric layer 711 is equal to 0.42a, and that the first and second dielectric layers 711, 712 respectively have refractive indices of 2.42 and 1.47, i.e., a refractive index difference of 0.95. The lattice constant a is equal to 134 nm.

[0048]FIG. 11 shows the presence of an omnidirectional photonic band gap in a frequency range between two dash lines in FIG. 11, i.e., between 0.291c / a and 0.305c / a, in the dispersion relation of guided modes in a photonic band structure of the omnidirectional photonic crystal 7 of the light emitting device of Example 2.

[0049]FIGS. 12a and 12b illustrate variation of the band gap size of the omnidirectional photonic band gap as a function of the thickness (d1) of the first dielectric layer 711...

example 3

[0053] The light emitting device of this Example differs from the first Example in that the light emitting diode 6 is capable of emitting a green light radiation having a wavelength range ranging from 480 nm to 550 nm, that the thickness (d1) of the first dielectric layer 711 is equal to 0.45a, and that the first and second dielectric layers 711, 712 respectively have refractive indices of 2.36 and 1.46, i.e., a refractive index difference of 0.9. The lattice constant a is equal to 151 nm.

[0054]FIG. 16 shows the presence of an omnidirectional photonic band gap in a frequency range between two dash lines in FIG. 16, i.e., between 0.297c / a and 0.308c / a, in the dispersion relation of guided modes in a photonic band structure of the omnidirectional photonic crystal 7 of the light emitting device of Example 3.

[0055]FIGS. 17a and 17b illustrate variation of the band gap size of the omnidirectional photonic band gap as a function of the thickness (d1) of the first dielectric layer 711 (T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com