Flow-path constituting body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

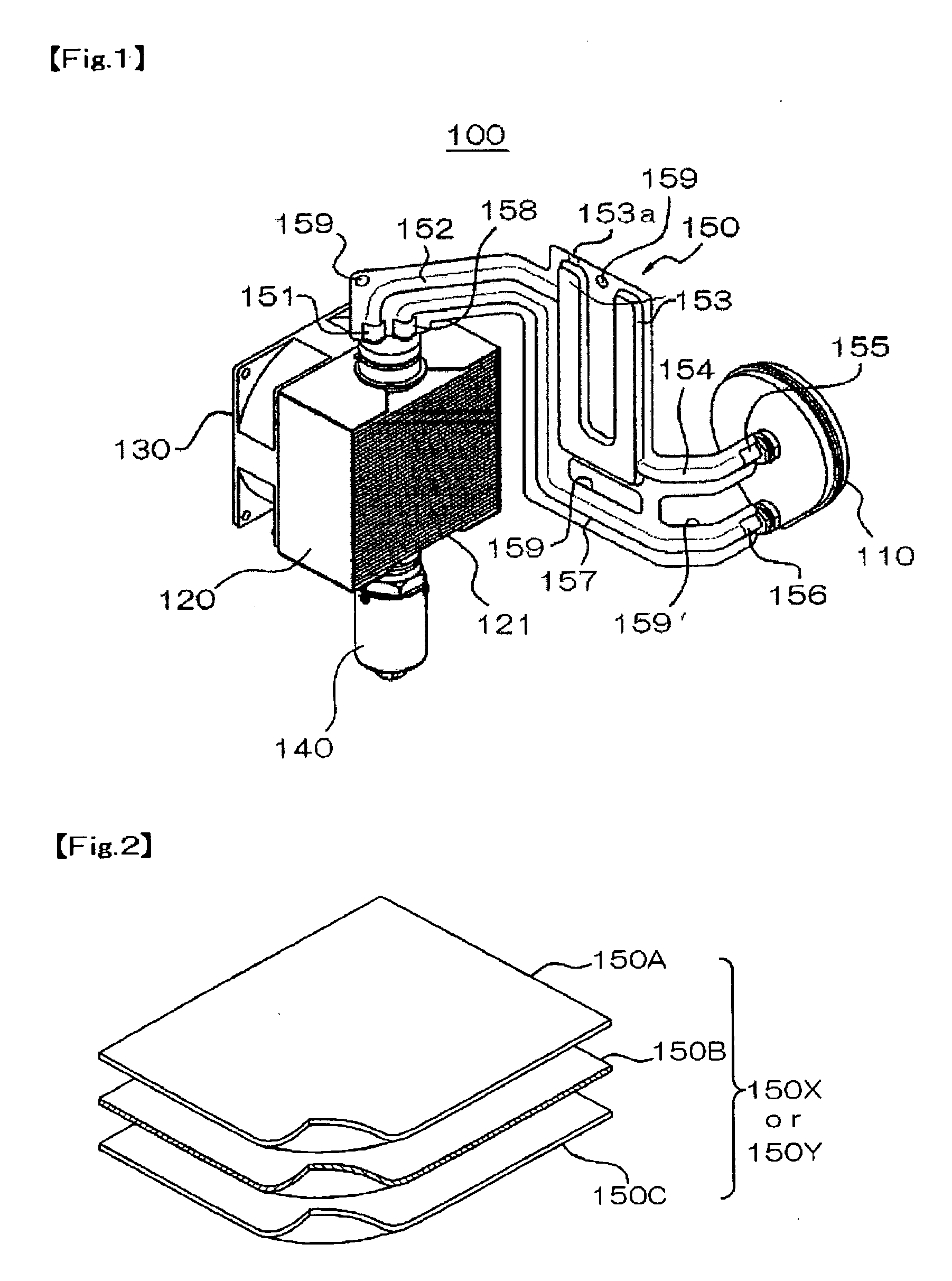

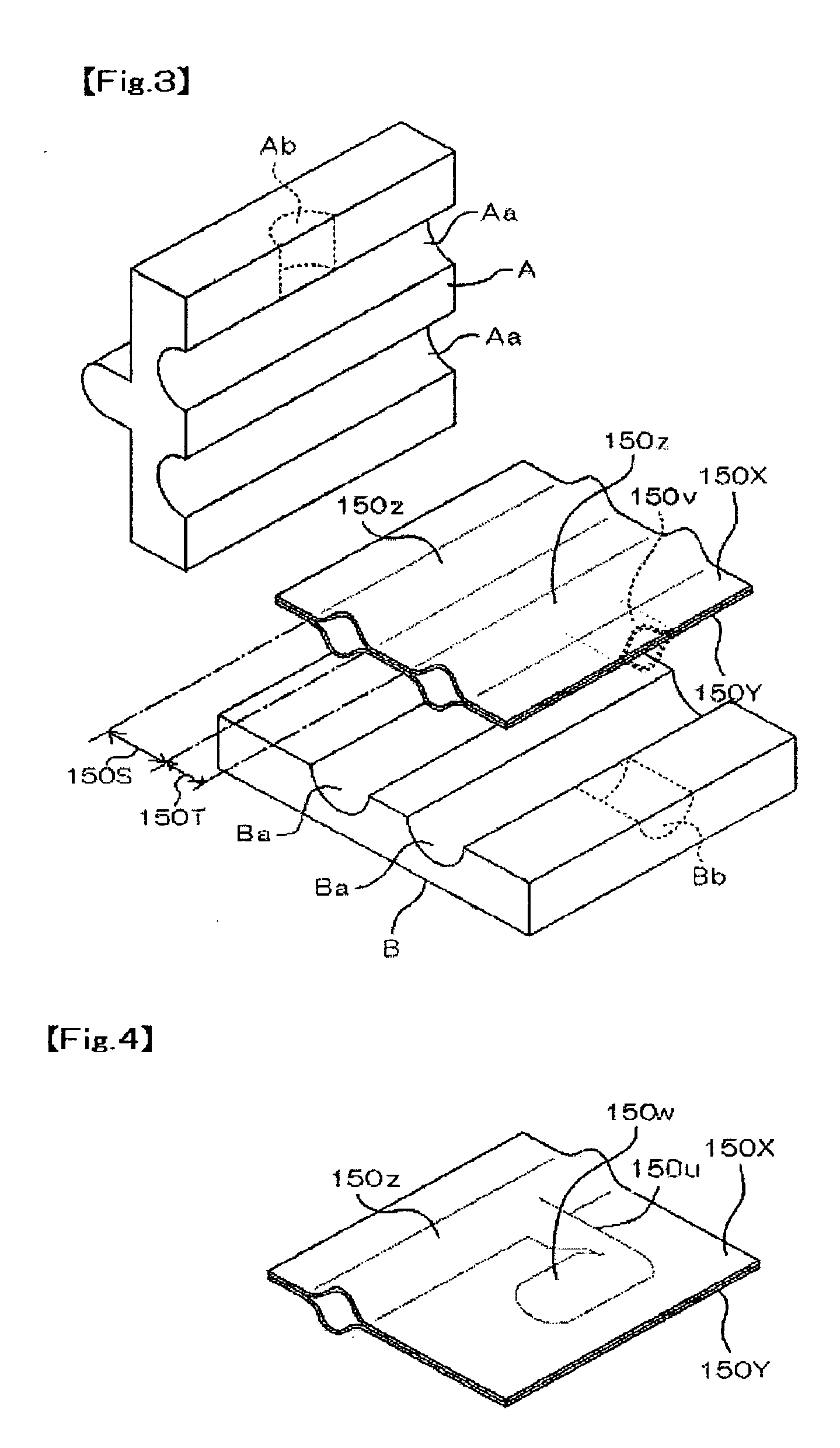

[0033] Embodiments of the present invention will be described below with reference to the accompanying drawings. Each of the embodiments described below is a flow-path constituting body which is used in a heat exchanging system including a heat receiving part, a heat radiation part and a fluid propulsion means. However, the flow-path constituting body in accordance with the present invention is not limited to the application described above. The flow-path constituting body can be widely applied to a constituting body for constructing a flow path which is arranged as a part of various systems.

[0034]FIG. 1 is a schematic construction perspective view showing an overview of a heat exchanging system 100 into which a flow-path constituting body in accordance with an embodiment of the present invention is integrated. The heat exchanging system 100 includes a heat receiving part (cooling jacket) 110, a heat radiation part (radiator) 120, a cooling fan 130 for blowing airflow to a heat rad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com