Stronger catalyst using selective washcoat location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

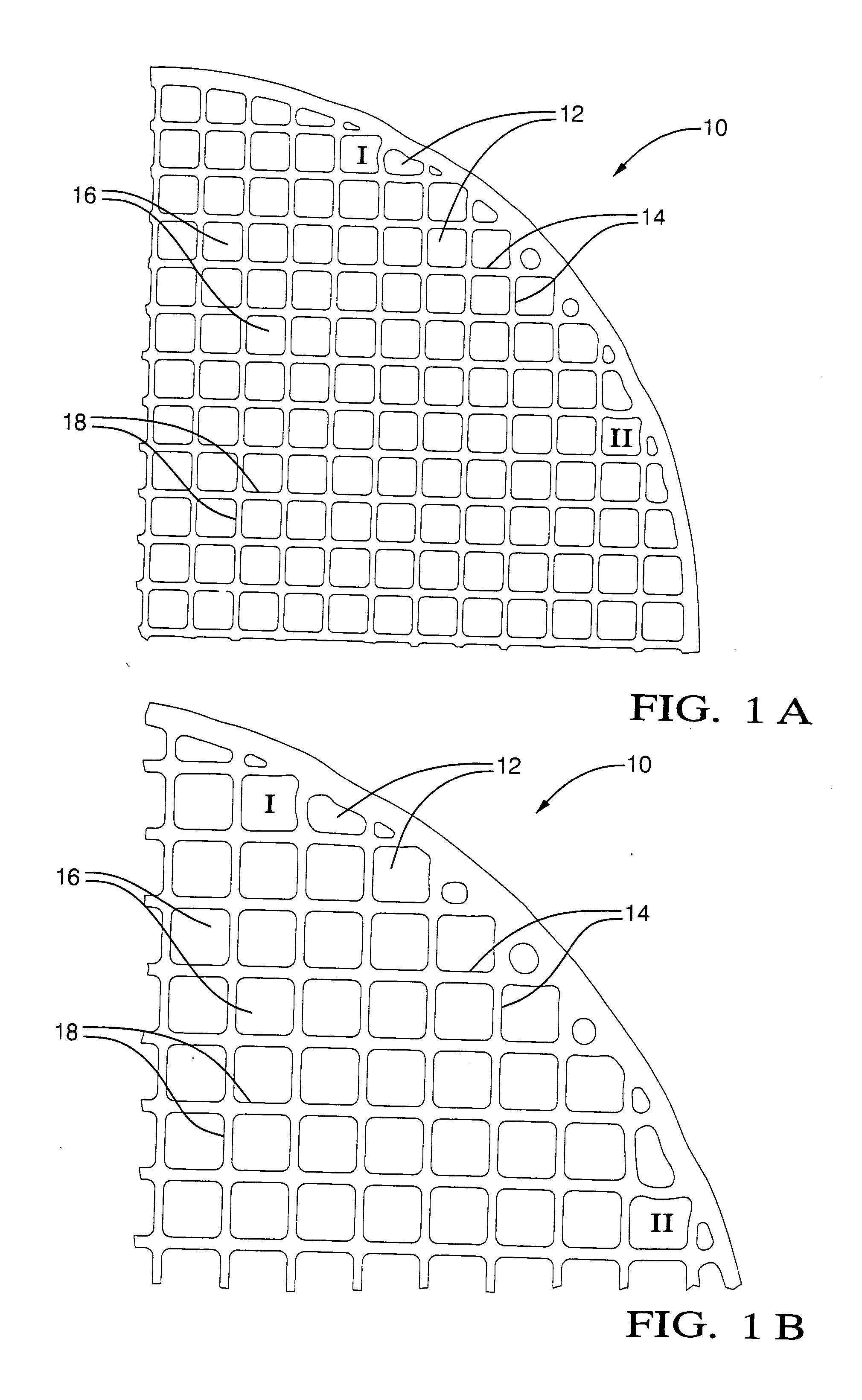

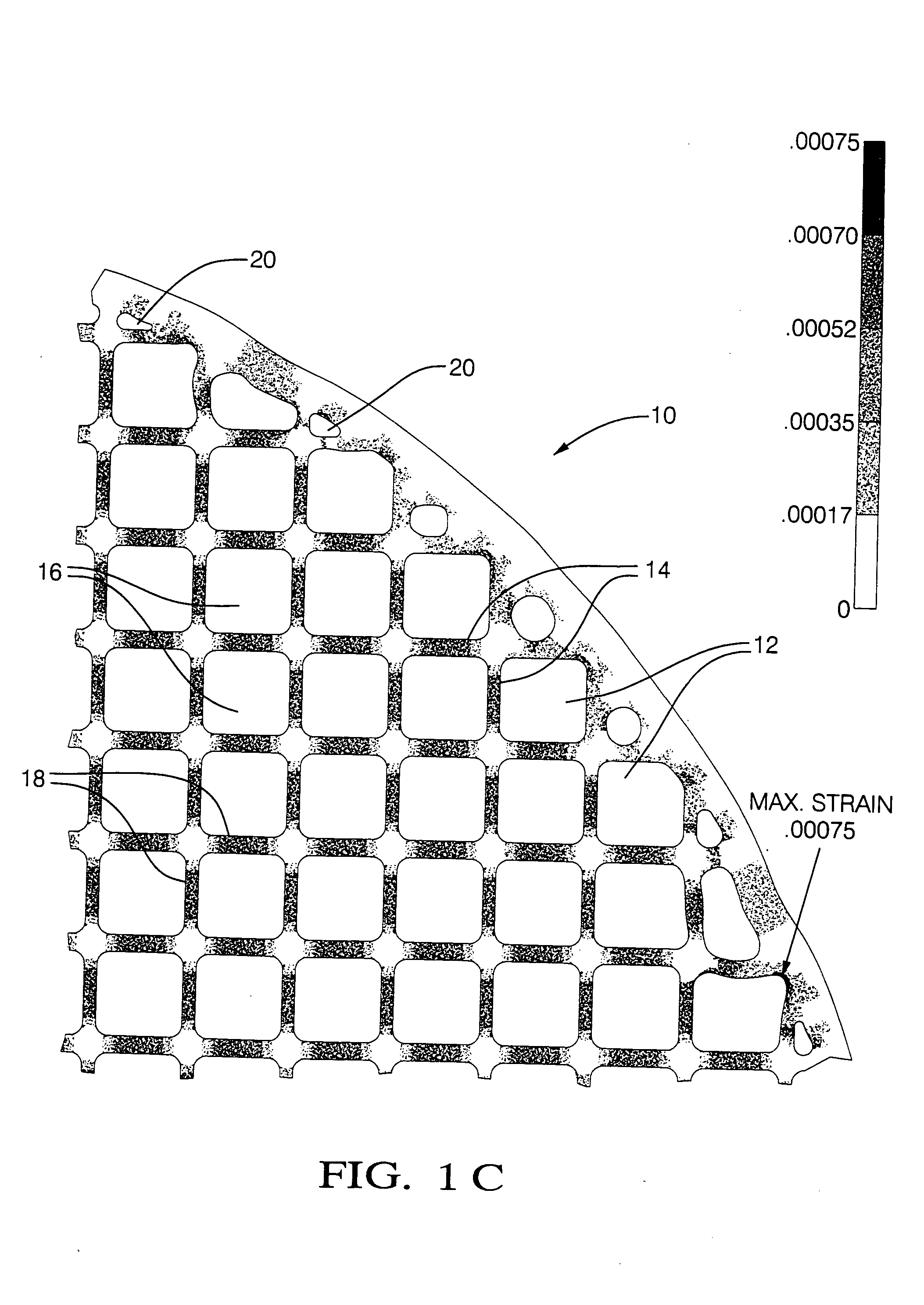

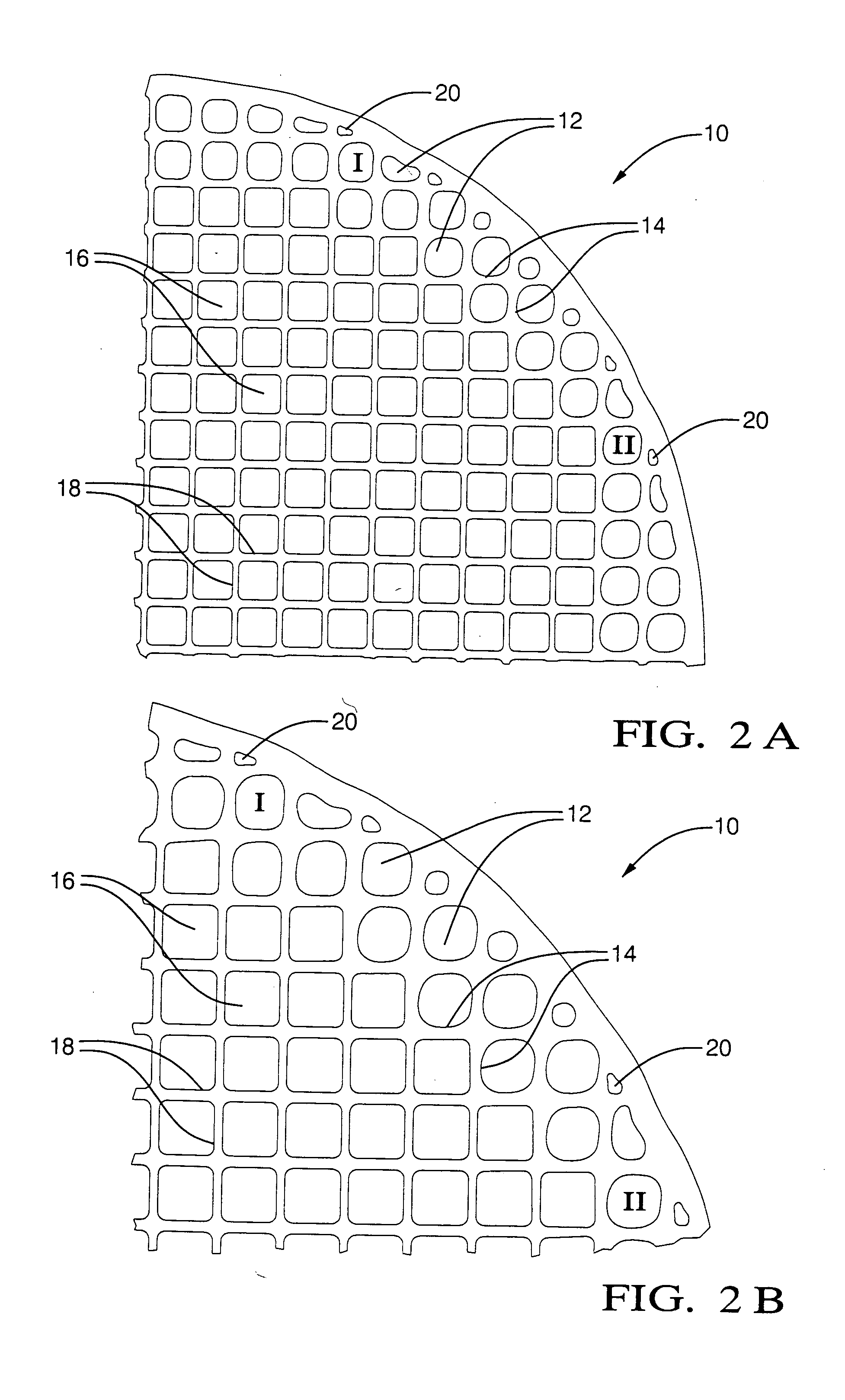

[0021] Turning now to the FIGURES, FIGS. 1A-2C show deformation and tensile strain responses to loads encountered during catalytic converter assembly based on computer modeling tests for thin-walled catalytic converter substrates having uniform washcoats (FIGS. 1A-1C, “non-invention”) and substrates having selective waschcoats in accordance with the present invention (FIGS. 2A-2C, “invention”).

[0022] In FIGS. 1A-1C (non-invention), a partial cross-section of a generally cylindrical thin-walled catalytic converter substrate 10 is shown. A uniform washcoat of about 1 mil is disposed on the substrate 10. FIGS. 2A-2C show a partial cross-section of a generally cylindrical thin-walled catalytic converter substrate 10 prepared in accordance with one possible embodiment of the present invention wherein the substrate 10 is selectively strengthened in the area of perimeter cells 12 by disposing a greater amount of waschcoat on substrate walls in the area of perimeter cells 12.

[0023] Comput...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com