Medical long object and method for producing the same

a technology of long objects and medical devices, applied in the field of medical long objects, can solve the problems of difficult to provide a lubricating coat, difficult to conduct marking on a curved surface, difficult to provide a desired position mark, etc., and achieve the effect of easy to see and excellent solvent resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0110] First, 0.2 g of Mica composition 1 and 3 g of a blue pigment were added to 99.8 g of polyurethane resin (ether type), and the mixture thus obtained was kneaded so that Mica composition 1 and the blue pigment were uniformly dispersed in the polyurethane resin.

[0111] Then, a core wire (made of a Ni—Ti alloy, having a diameter of 0.6 mm) was coated with the resultant resin containing a laser color developing agent by extrusion molding so as to have an outer diameter of 0.8 mm, whereby a guide wire was obtained.

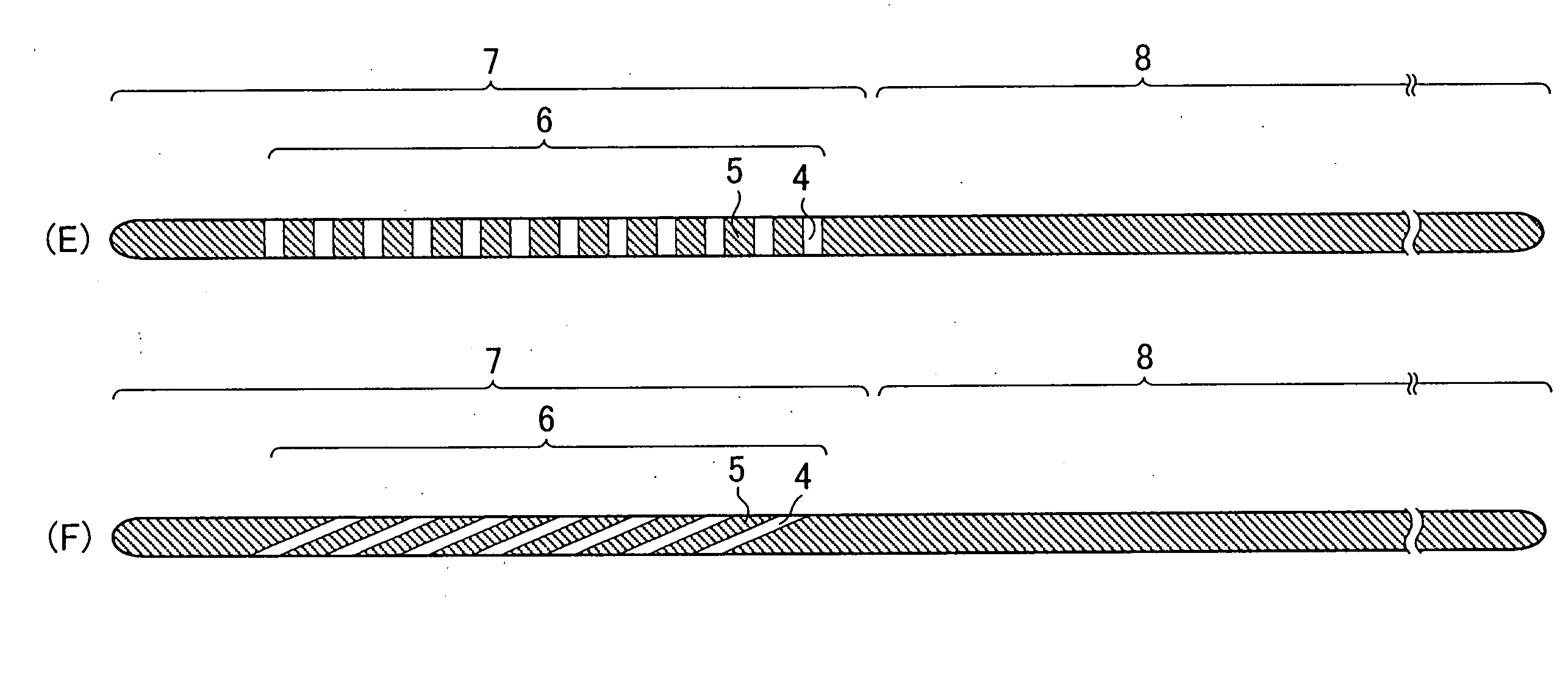

[0112] Thereafter, the surface formed of the resin containing a laser color developing agent was irradiated with YAG laser light by a laser light irradiation method shown in FIG. 1, whereby a mark was formed. The movement speed of the guide wire was 300 mm / min., and the energy output of an irradiation origin was 1800 W.

[0113] Furthermore, the surface was coated with a maleic anhydride ethyl ester copolymer by dipping, followed by being dried. Thus, a medical long object...

example 2

[0114] A medical long object (guide wire) of the present invention was obtained by the same method as that of Example 1, except that irradiation with laser light was conducted after coating of a maleic anhydride ethyl ester copolymer in place of conducting coating of a maleic anhydride ethyl ester copolymer after irradiation with laser light.

example 3

[0115] First, 0 to 1 g of Iriodin (laser color developing agent), 30 to 70 g of tungsten, and 0 to 10 g of fluorine powder were added to 30 to 70 g of polyurethane resin respectively, and the mixture thus obtained was kneaded so that these components were uniformly dispersed.

[0116] Then, core wires (made of a Ni—Ti alloy) previously tapered were coated with the resultant resin containing a laser color developing agent by extrusion molding so as to have outer diameters respectively shown in Table 1.

[0117] Each core wire thus obtained was cut in predetermined length and the core wire was coated (hydrophilic polymer coat portion) with a hydrophilic polymer (a maleic anhydride ester copolymer) to a length shown in Table 1 from a tip end portion by dipping. Thereafter, the surface formed of the resin containing a laser color developing agent was irradiated with YAG laser light by the laser light irradiation method shown in FIG. 1, whereby a mark was formed (visual marker portion). The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com