Transport line with grooved microchannels for two-phase heat dissipation on devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

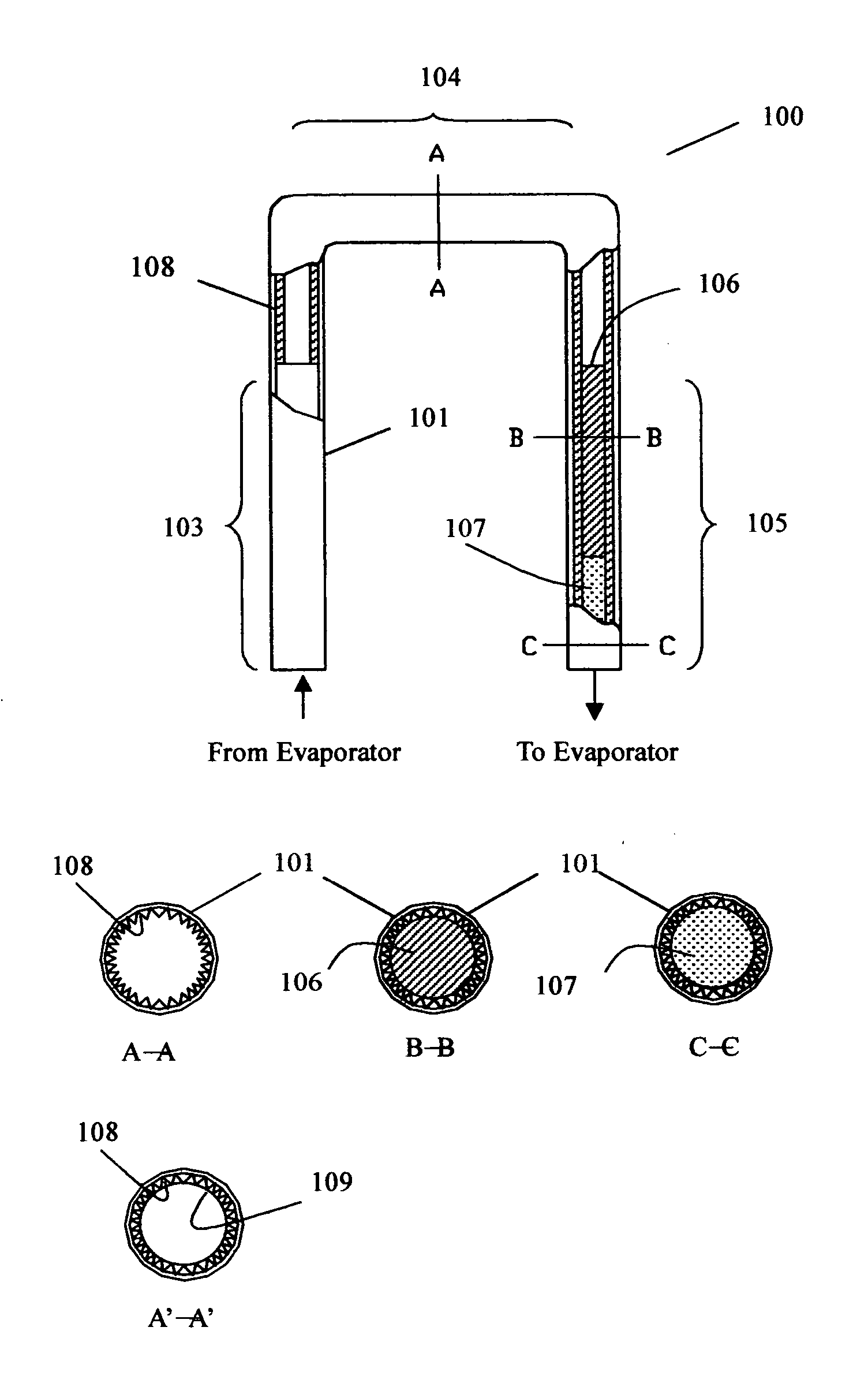

[0020]FIG. 3 shows the present invention. The flow path of the transport line 100 has sequential three sections: a vapor line 103, a condensation section 104, and a liquid line 105. The inner wall of the tubing 101 of the condensation section and liquid line is made with grooved microchannels 102, which can be made by extrusion molding during the fabrication of the tubing 101. The grooved microchannel has a hydraulic diameter smaller than the 500 μm. The cross-section of the groove can be triangular, rectangular, trapezoidal, wavy, or others. A plug 106 is inserted into the core of the liquid line 105 to reduce its effective cross-sectional area to only the groove microchannels, to enhance the pumping force. The plug 106 can be fabricated with metal, plastic or other heat resistant materials. The bottom corners of the grooved microchannels as shown in A-A section view help to collect the condensed liquid and convey it to the liquid line section. With the grooved microchannels closed...

second embodiment

[0023]FIG. 4 shows the present invention. This embodiment differs from the first embodiment in that a layer of wire mesh 109 is added to cover the grooved microchannels 102 for at least the condensation section 104, as shown in cross-section A-A, to improve the pumping ability. The material of the wire mesh can be metals or nonmetals.

third embodiment

[0024]FIG. 5 shows the present invention. The grooved microchannels are fabricated with a layer of a corrugated wire mesh to line in along the inner wall of the tubing 101 of the transport line. The vapor section 103 can be a tube only or inserted with a corrugated wire mesh as shown in the cross-section A-A, The condensation section 104 has a cross-section A-A with corrugated wire mesh lining 108. The liquid line section has a cross-section B-B with corrugated wire mesh enclosing a plug 106 which reduces the effective cross-sectional area for the liquid to flow. The wire mesh is corrugated with a cross-section shape either of triangular, rectangular, trapezoidal, wavy, or other groove shape with equivalent function. The corrugated wire mesh is basically inserted into the condensation section 104 and liquid line 105. A plug 106 is optionally inserted as a core in the liquid line 105 to reduce its effective cross-sectional area. An additional layer of wire mesh 109 can be optionally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com