Custom fitted helmet and method of making the same

a custom fitted helmet and fitting technology, applied in the field of custom fitted helmets, can solve the problems of not being comfortable to wear, too loose fitting helmets can be as or nearly as catastrophic, and the fit is too tight in certain aspects or along certain locations, so as to achieve economic and comfort for wearers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] As used herein, when a range such as 5 to 25 (or 5-25) is given, this means preferably at least 5 and, separately and independently, preferably not more than 25.

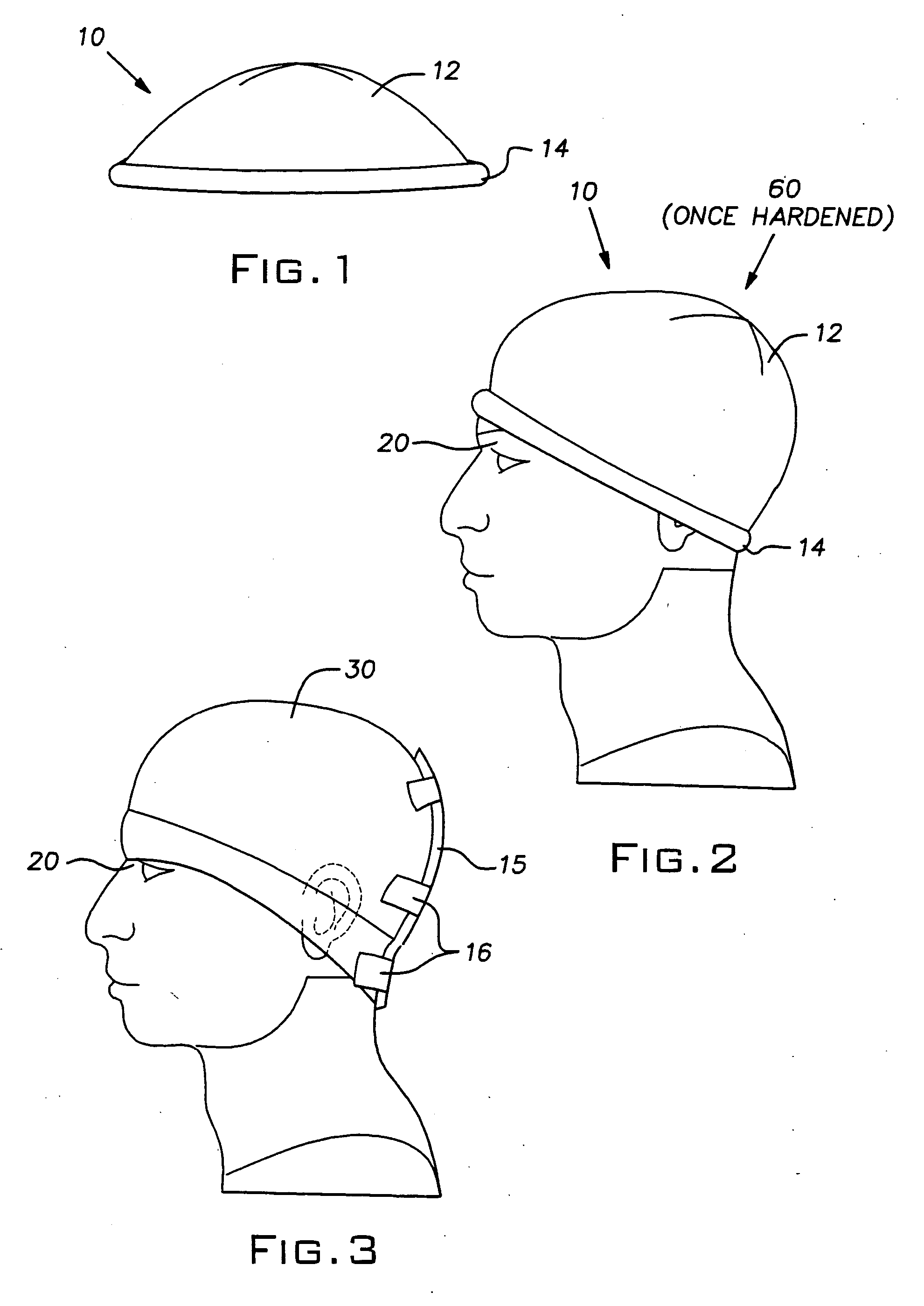

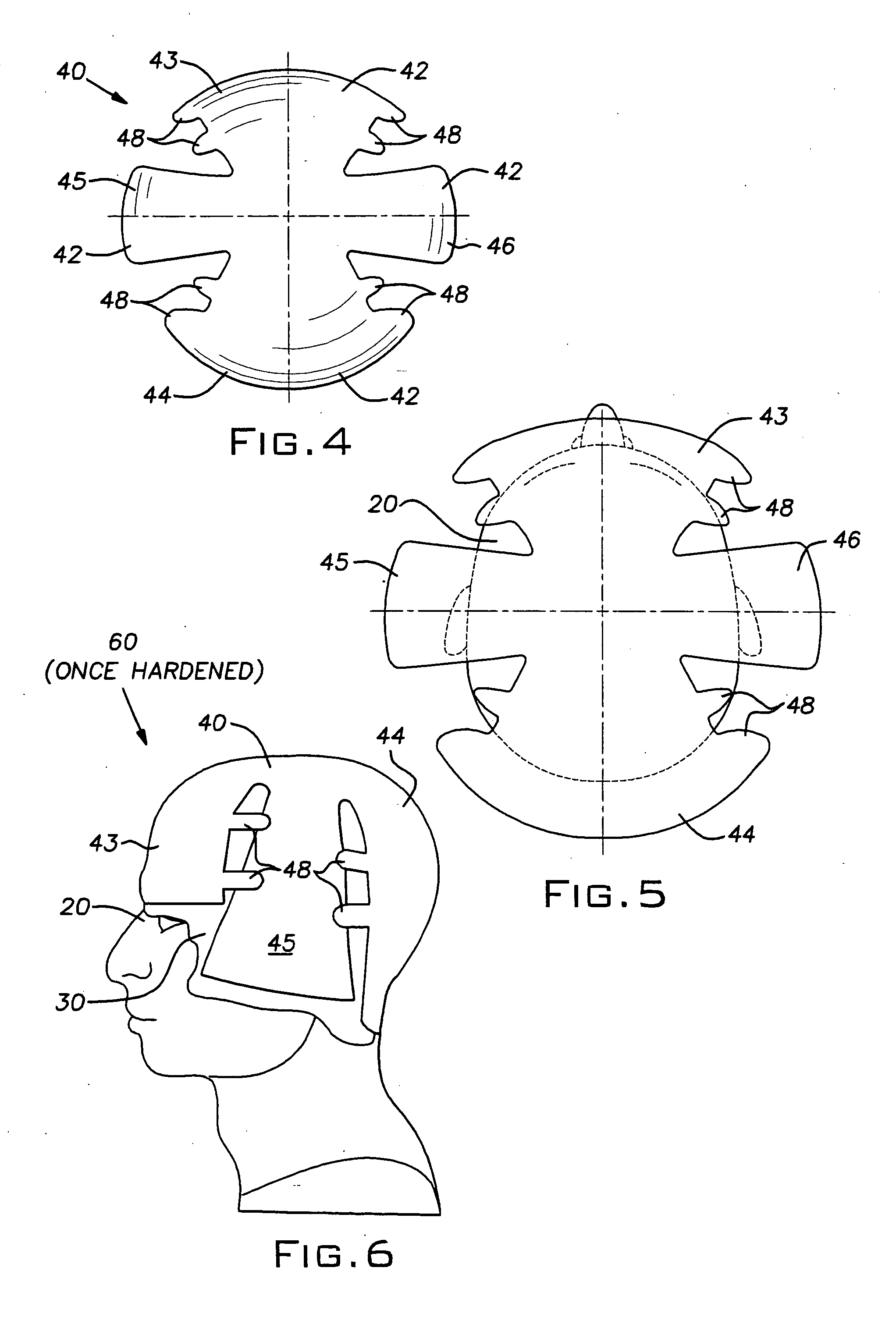

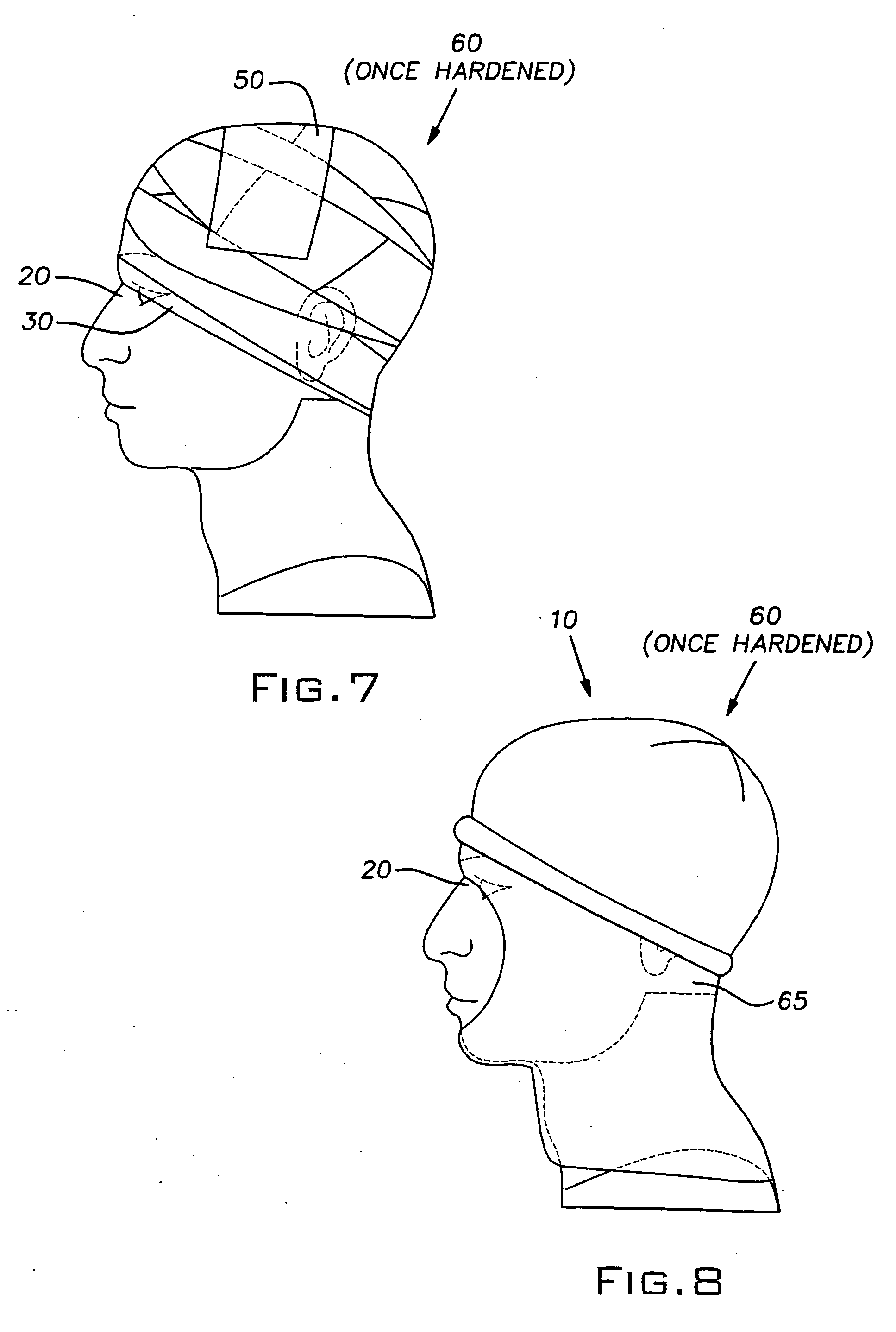

[0025] The method of the present invention includes first making a headform that conforms to the shape of the wearer's head. The headform is made by positioning or wrapping an appropriate shape-forming means over and against the wearer's head. When the shape-forming means is applied to the head, it is in a softened or flexible state such that it can bend or flex or stretch to conform to the unique contour of the individual head to which it is being applied. Once the shape-forming means has been applied and conformed snugly to the shape and contour of the individual's head, it is hardened or rigidized such that it is no longer soft or flexible, thereby yielding a hardened headform 60 that conforms or substantially conforms to the shape and contour of the wearer's head.

[0026] Once hardened, the headform is carefully r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com