Semiconductor processor control systems, semiconductor processor systems, and systems configured to provide a semiconductor workpiece process fluid

a technology of semiconductor workpieces and control systems, applied in the direction of grinding machine components, manufacturing tools, lapping machines, etc., can solve the problems of stray particles produced by polishing and adverse effects of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] This disclosure of the invention is submitted in furtherance of the constitutional purposes of the U.S. Patent Laws “to promote the progress of science and useful arts” (Article 1, Section 8).

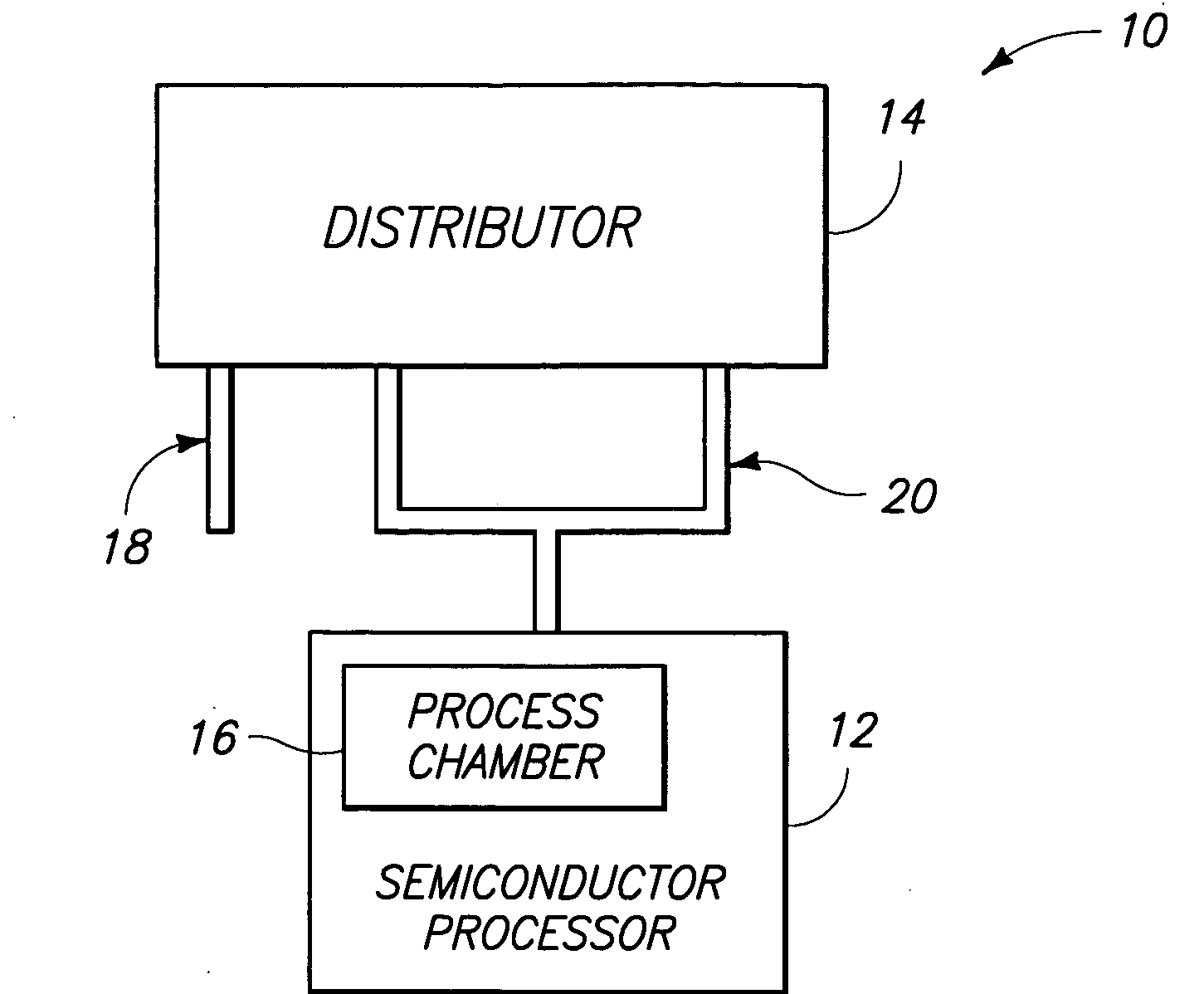

[0045] Referring to FIG. 1, a semiconductor processing system 10 is illustrated. The depicted semiconductor processing system 10 includes a semiconductor processor 12 coupled with a distributor 14. Semiconductor processor 12 includes a process chamber 16 configured to receive a semiconductor workpiece, such as a silicon wafer. In an exemplary configuration, semiconductor processor 12 is implemented as a chemical-mechanical polishing processing tool.

[0046] Distributor 14 is configured to supply a subject material for use in semiconductor workpiece processing operations. For example, distributor 14 can supply a subject material comprising a slurry to semiconductor processor 12 for chemical-mechanical polishing applications.

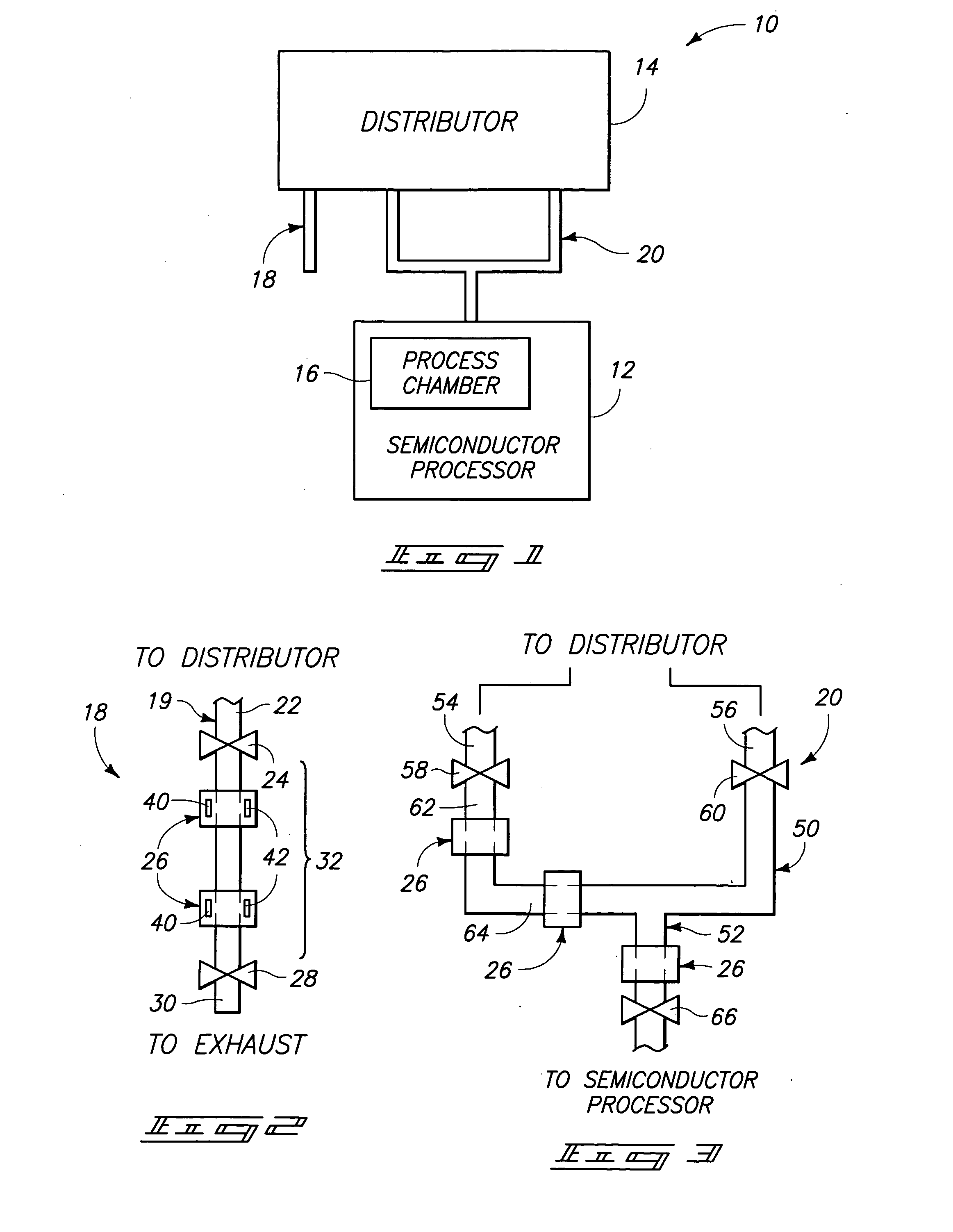

[0047] Exemplary conduits or piping of semiconductor processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com