Drilling fluid, apparatus, and method

a technology of drilling fluid and drilling fluid, which is applied in the direction of earth drilling and mining, chemistry apparatus and processes, and well accessories, etc., can solve the problems of oil-based fluids that oil-based fluids are difficult to maintain, etc., to achieve the effect of promoting the stability of the borehol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

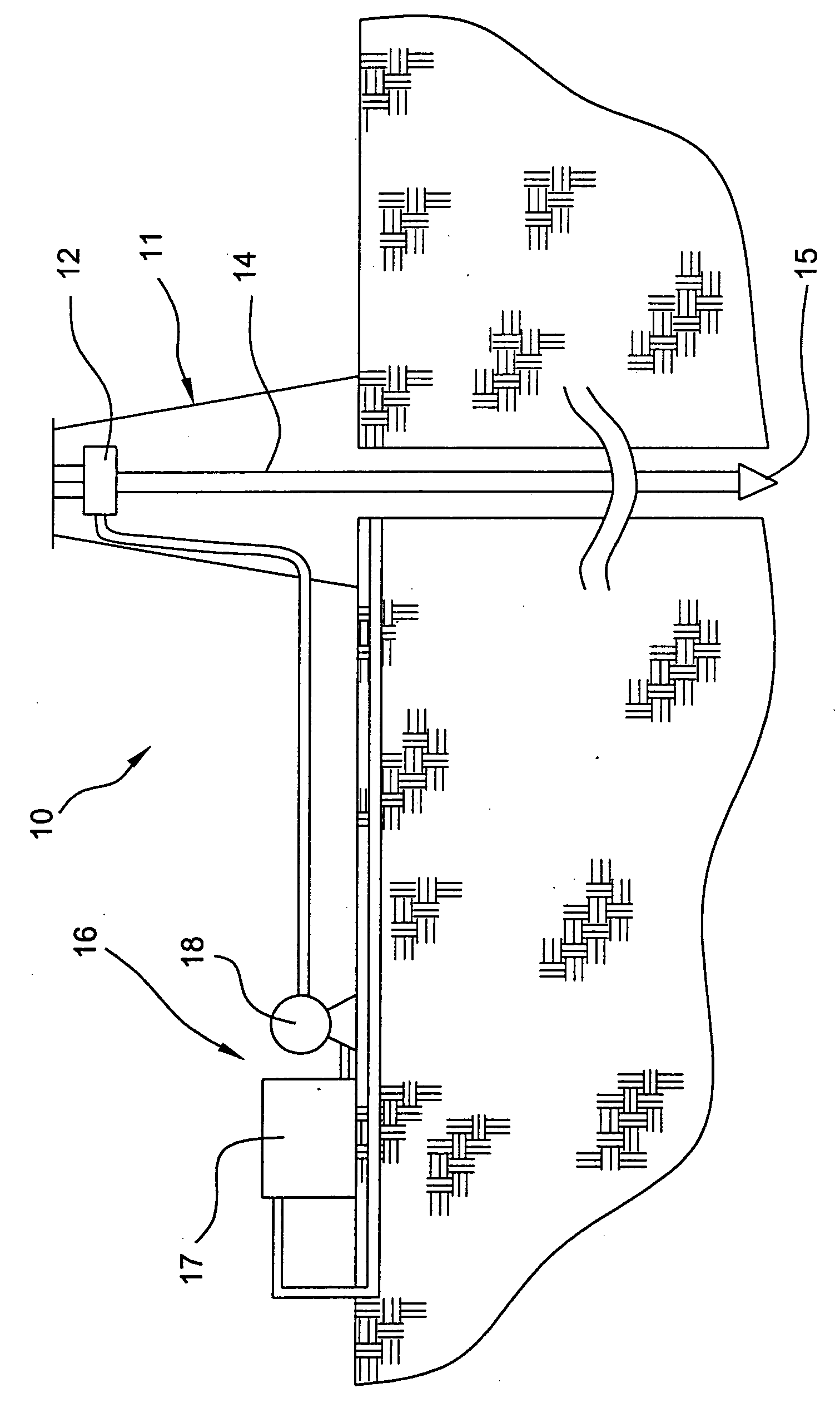

Image

Examples

example 1

MeG+Maltodextrin

[0050] Drilling fluids were prepared using methyl glucoside and maltodextrin, and the bentonite stability test was repeated for each fluid. The following results were obtained. Maltodextrin percentages in these tables express weight percent maltodextrin by dry basis of methyl glucoside.

6 Drilling Fluid 1 hr. 2 hr. 4 hr. 8 hr. 24 hr. 365 + 5% M040 1 1 1.5 1.5 2 365 + 5% M100 1 1 1.5 1.5 2.5 365 + 5% M180 1.5 1.5 2 2 4

[0051]

7 Drilling Fluid 1 hr. 2 hr. 4 hr. 20 hr. 30 hr. 365 + 1% M040 1.5 2 2.5 4 4 365 + 3% M040 1 1.5 1.5 2.5 3

[0052]

8 Drilling Fluid 1 hr. 4 hr. 8 hr. 24 hr. 365 + 0.5% M100 1.5 2 3.5 4 365 + 1% M100 1 1.5 1.5 3.5

[0053] As set forth above, the bentonite pellets generally were more stable in the drilling fluids of Example 1 than in the control drilling fluids.

example 2

MeG+Maltodextrin+NaCl

[0054] Drilling fluids were prepared using MeG, maltrodextrin, and sodium chloride. The bentonite stability test was repeated for each fluid, and the following results were obtained. Sodium chloride percentages in these tables express weight percent sodium chloride by dry basis weight of methyl glucoside.

9 Drilling Fluid 1 hr. 2 hr. 4 hr. 8 hr. 24 hr. 365 + 5% 1 1 1 1.5 2 M040 + 10% NaCl 365 + 5% 1 1 1.5 1.5 2 M100 + 10% NaCl 365 + 5% 1 1.5 1.5 2 4 M180 + 10% NaCl

[0055]

10 Drilling Fluid 1 hr. 2 hr. 4 hr. 20 hr. 30 hr. 365 + 1% 1.5 1.5 1.5 2 3 M040 + 5% NaCl 365 + 3% 1 1 1.5 2 3 M100 + 5% NaCl

[0056]

11 Drilling Fluid 1 hr. 4 hr. 8 hr. 24 hr. 365 + 0.5% M040 + 2% NaCl 1.5 1.5 2.5 3.5 365 + 1% M100 + 2% NaCl 1 1.5 1.5 3 365 + 0.5% M100 + 5% NaCl 1.5 2 2 3.5 365 + 1% M100 + 5% NaCl 1 1.5 1.5 3.5

[0057] As seen, the addition of sodium chloride to the drilling fluid rendered the fluid retention less aggressive toward the bentonite pellets.

example 3

MeG+HC

[0058] Drilling fluids were prepared using MeG and the hemicellulose fraction of alkaline treated corn hulls. The bentonite stability tests were repeated, and the following examples were obtained. Hemicellulose percentages in these tables are expressed as weight percent dry hemicellulose provided in the HC solution by dry basis MeG.

12 Drilling Fluid 1 hr. 2 hr. 4 hr. 8 hr. 365 + 0.6% hemicellulose 1 1 1 1.5 365 + 0.6% hemicellulose 2.5 3.5 4 4.5 (solution diluted to 50%)

[0059]

13 Drilling Fluid 1 hr. 2 hr. 4 hr. 20 hr. 30 hr. 365 + 1% 1 1 1 2 2.5 hemicellulose

[0060]

14 Drilling Fluid 1 hr. 2 hr. 4 hr. 8 hr. 24 hr. 48 hr. 207 + 0.5% 1 1 1 1 1.5 1.5 hemicellulose 365 + 0.6% 1 1 1 1.5 -- --hemicellulose

[0061] As seen, the bentonite pellets were substantially more stable in the drilling fluids prepared using MeG and hemicellulose than in the drilling fluids prepared using only MeG.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| v/v | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com