Deformable pull plug

a pull plug and deformation technology, applied in the direction of liquid handling, application, and closure using stoppers, can solve the problems of affecting the ability of the operator, affecting the appearance of the coating part, and further affecting the ability to form a complete seal, so as to reduce the defect of the coating and improve the appearance of the coated par

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

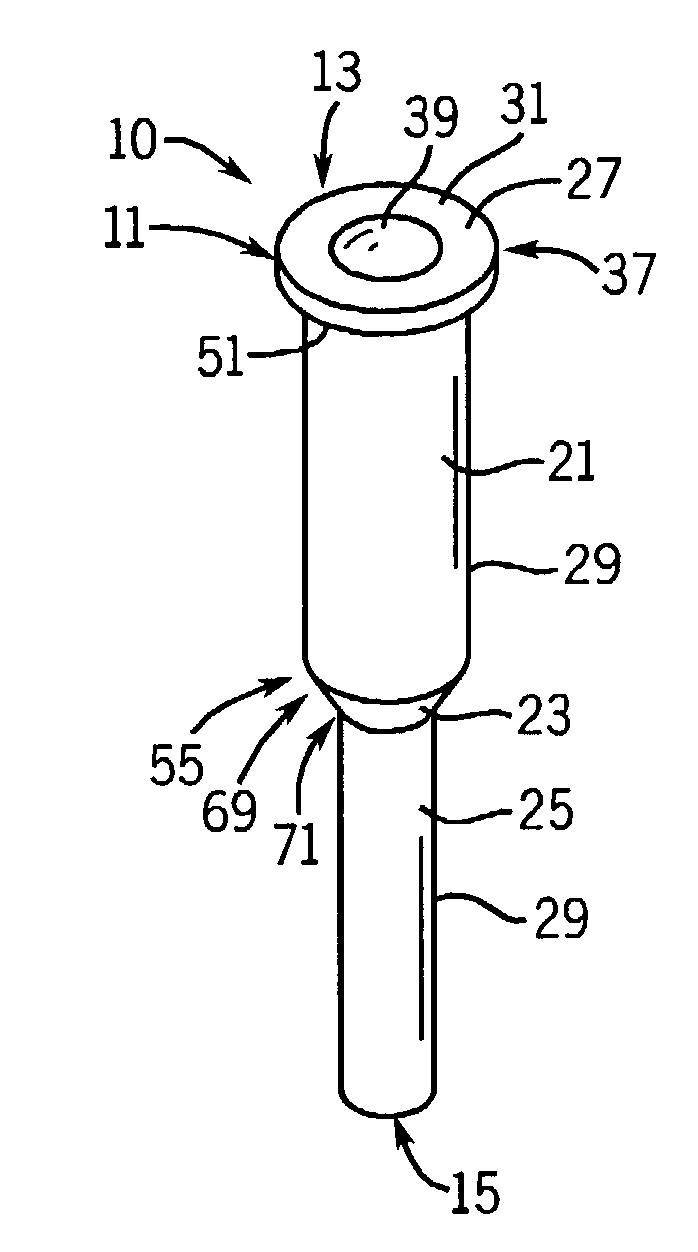

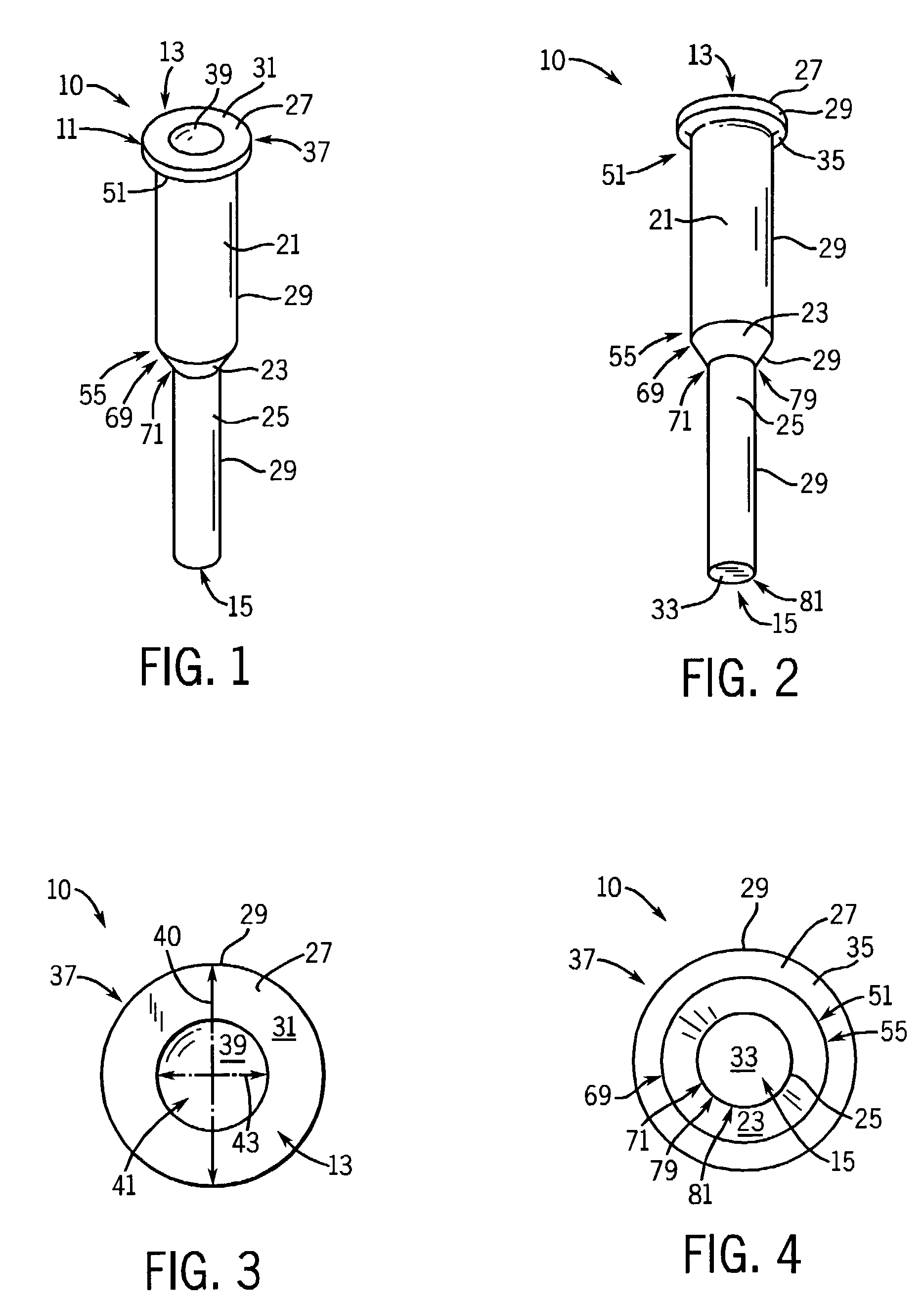

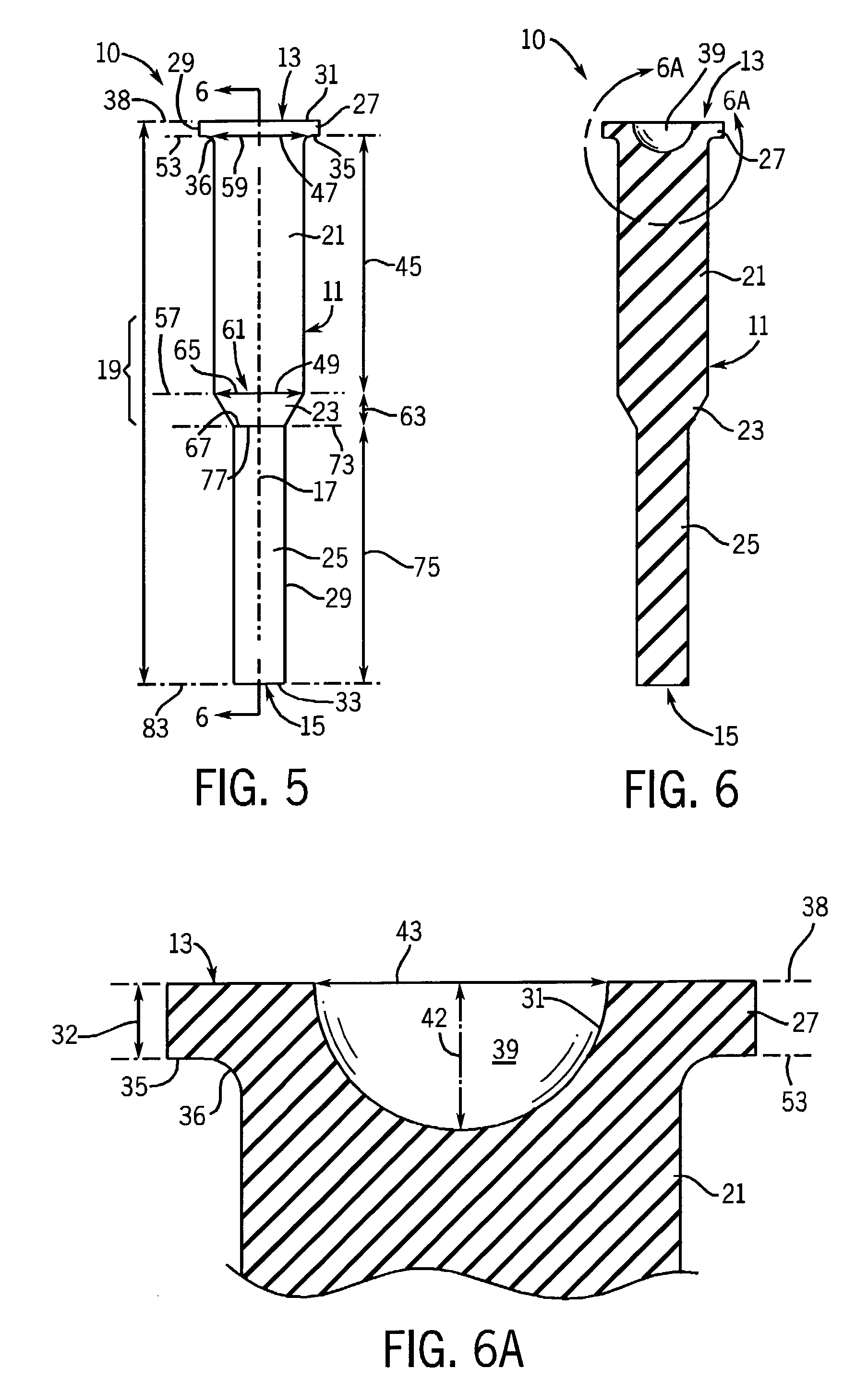

example 1

[0078] An important advantage of the inventive plug 10 is that a single pull plug 10 can be used to mask a wide range of part openings each having different opening sizes. As a result, an operator need not maintain as great an inventory of plugs for the operator's coating or other operation. Since thousands of plugs in different sizes may be needed to operate a large scale coating operation, this can result in significant savings in inventory and material for the operator. This advantageous result is possible because of the combination of (1) the void volume 39; and (2) the novel plug body 11 made of the highly deformable material having a low durometer value of 35-45 on the Shore A scale. The combination of these elements permits one plug 10 to deform to fit many smaller part openings (such as opening 85).

[0079] A comparison of prior art pull plugs and pull plugs of the invention was conducted to determine the range of part openings which could be fully masked with a single size pl...

example 2

[0082] A further important advantage of the inventive plug 10 is that a single pull plug 10 can be repeatedly reused during the course of many coating cycles. The ability to reuse the plug permits an operator to maintain a smaller inventory of plugs for the operator's coating or other operation. Again, this can result in significant savings in inventory and material for the operator.

[0083] Control and inventive pull plugs having the geometry of the plugs shown in FIGS. 1-12 were manufactured. The plugs had identical flanges 27 and plug 21, transition 23 and tail 25 segments. Both plugs were made of virgin silicone. The plugs differed only in that the control plug lacked a void volume 39 and had a durometer of 55+ / -5 on the Shore A scale while the inventive plug included a hemispherical void volume 39 as shown in FIGS. 1-12 and had a durometer of 40+ / -5 on the Shore A scale.

[0084] The pull plugs were inserted into a 1 / 4-20 threaded opening in a template and were pulled completely thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com