Method for manufacturong heat exchanger

a heat exchanger and manufacturing method technology, applied in the direction of manufacturing tools, soldering devices, light and heating equipment, etc., can solve the problems of increasing material costs and weight, increasing the weight of the fin, and the total joining area of the portions to be joined is very small, so as to avoid the effect of zn erosion protection, low melting point, and smooth diffusion of zn for sacrifi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 8

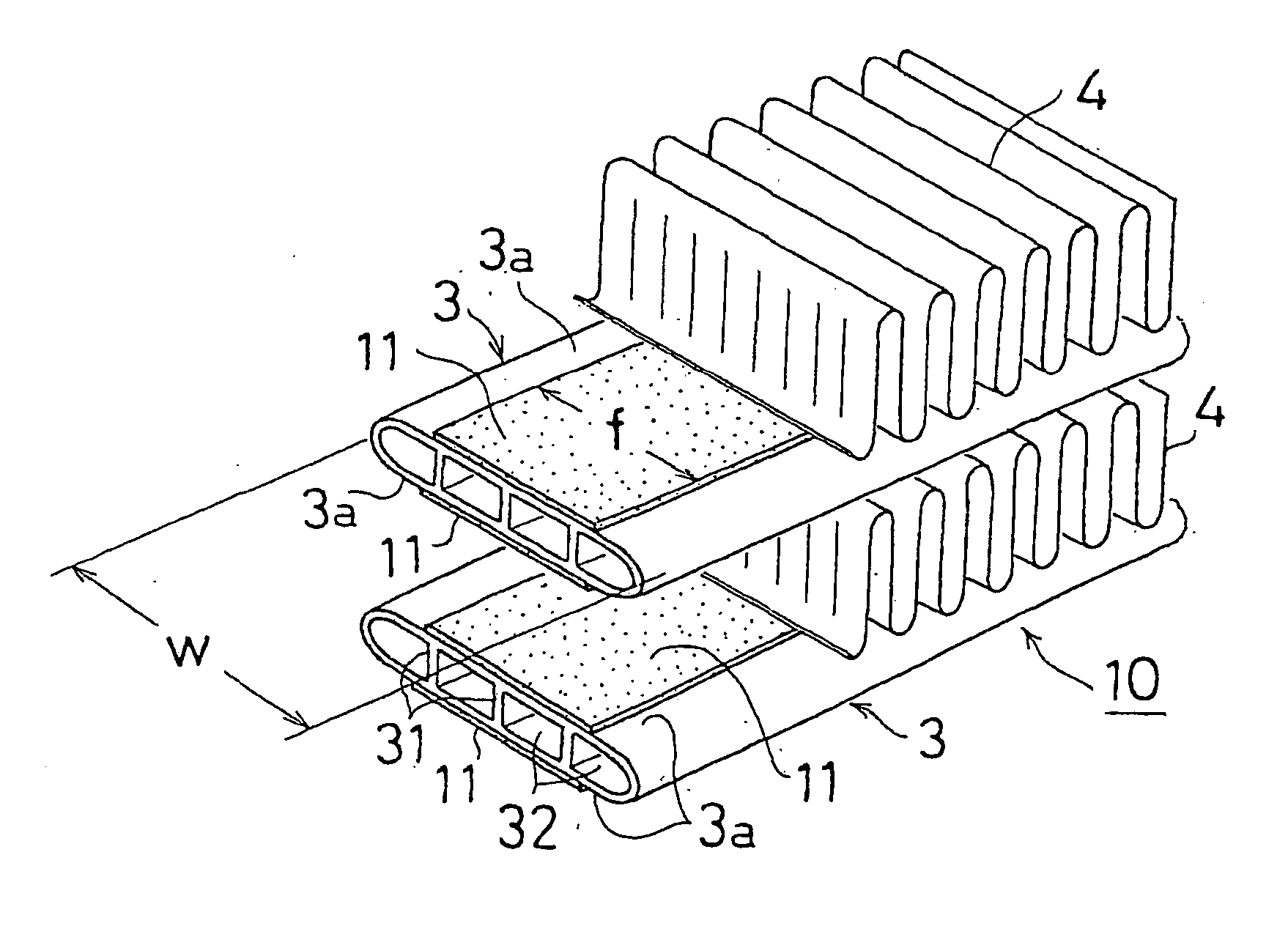

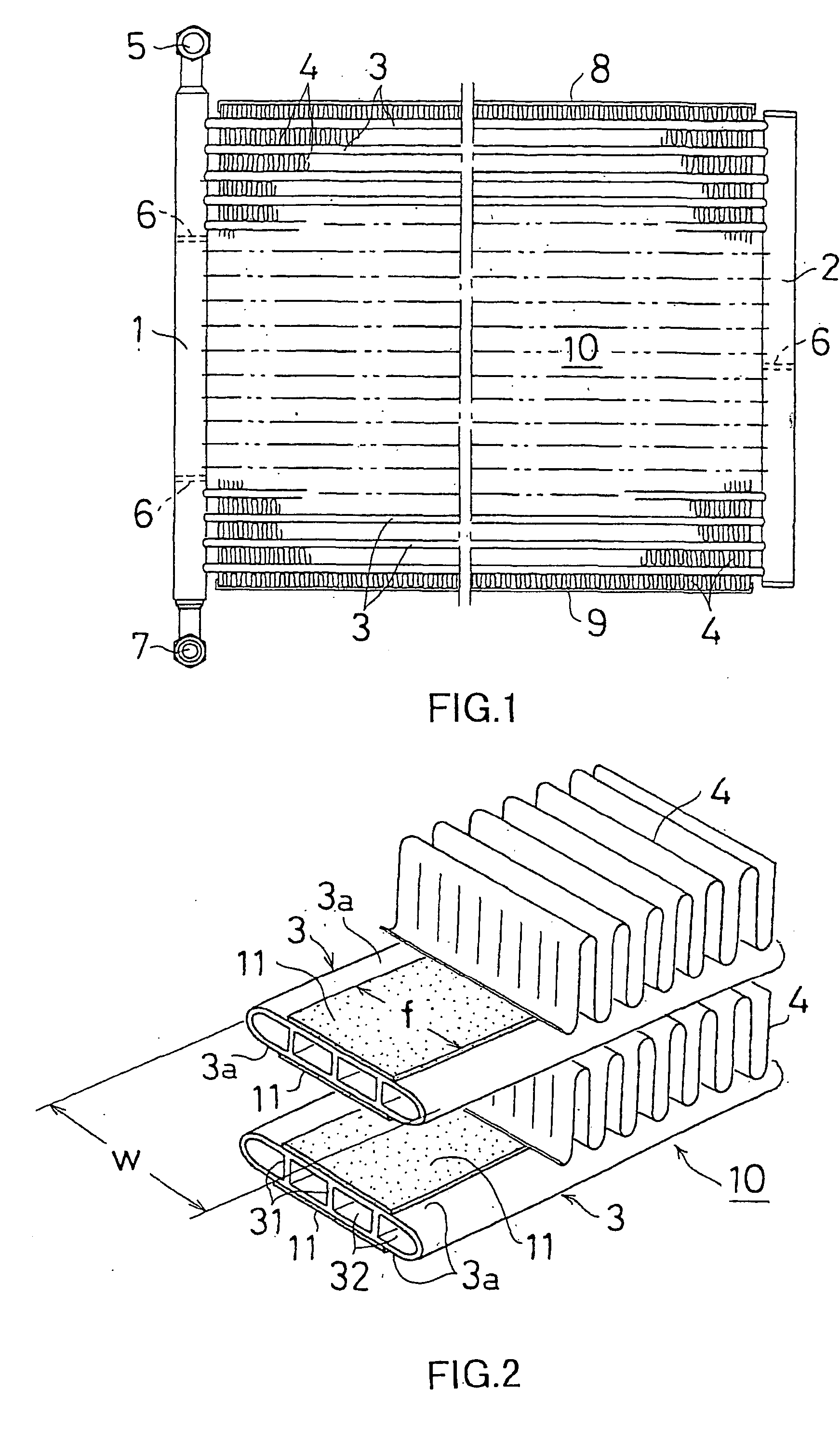

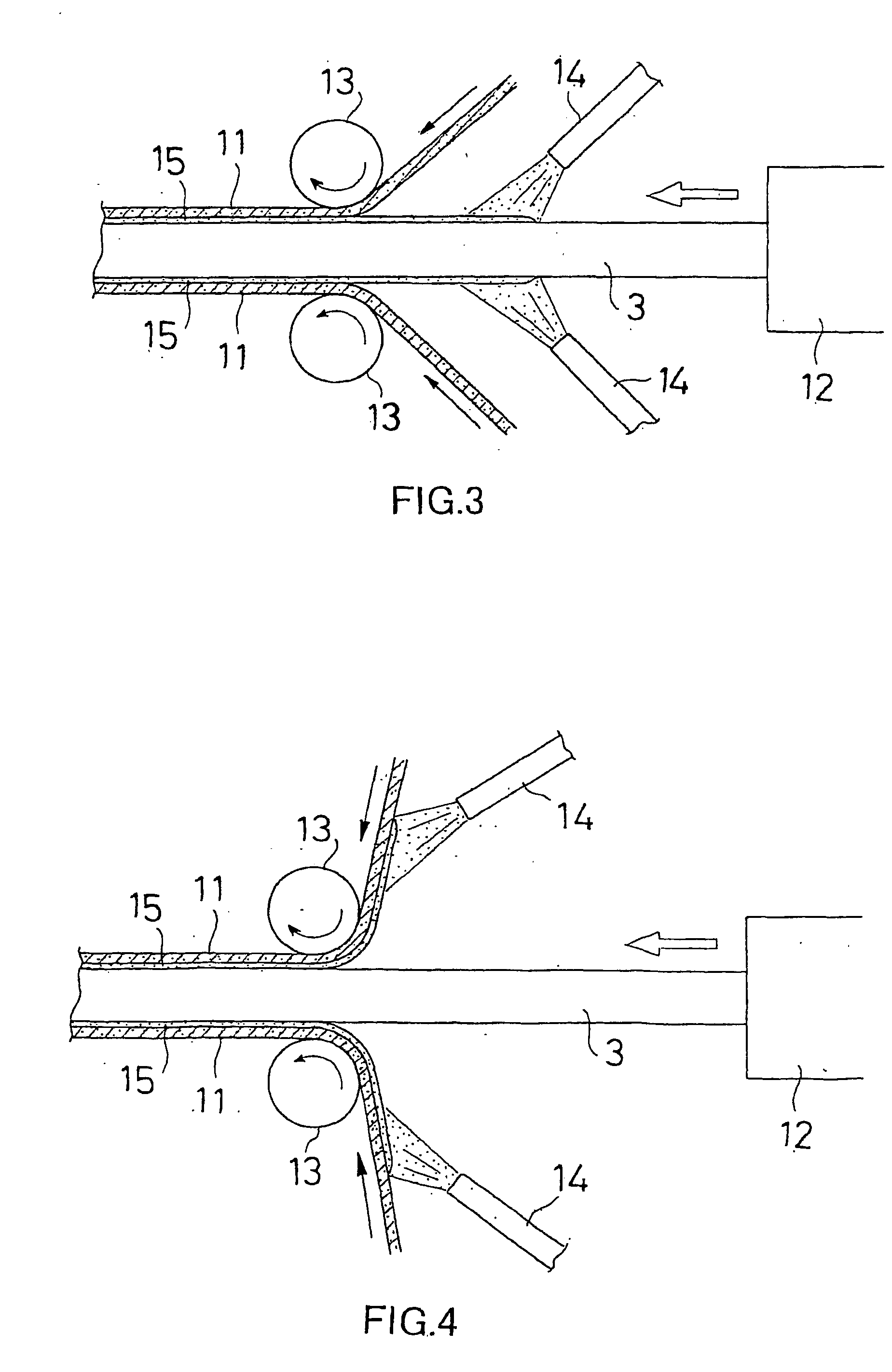

[0042] As shown in FIG. 3, on both the upper and lower flat surfaces of the aluminum flat tube 3 which was being continuously extruded from the extruding machine 12, Zn was thermally sprayed from the nozzles 14 and 14 located at the position immediately after the extrusion to form sprayed metal coatings 15 and 15. Immediately after the formation of the sprayed metal coatings 15 and 15, brazing foils 11 and 11 made of Al--Si alloy (comprising: 8 wt % of Si; and the balance Al and impurities) were adhered on the sprayed metal; coatings 15 and 15 by using pressure rollers 13 and 13. Thus, a flat tube 3 on which brazing foils 11 and 11 were adhered was obtained.

[0043] The aforementioned flat tube 3 was manufactured by extruding AA 1100 aluminum alloy at the extrusion rate of 50 m / min and the temperature of 450.degree. C. into a flat tube having a width W of 16 mm, a thickness (height) of 1.6 mm, a wall thickness of 0.3 mm and four follow portions.

[0044] The spraying of Zn was performed ...

examples 9 and 10

[0046] As the spraying metal to be thermally sprayed onto the upper and lower surfaces of the flat tube 3 immediately after the extrusion, in place of Zn used in the aforementioned examples 1 to 8, Zn--Sn alloy was used. The other conditions were the same as in the example 2. Thus, the so-called parallel flow type heat exchanger was manufactured.

example 11

[0047] As the materials of the brazing foil, Al--Si--Zn alloy (comprising: 8 wt % of Si; 3 wt % of Zn; and the balance Al and impurities) was employed. The other conditions were the same as in the example 6. Thus, the so-called parallel flow type heat exchanger was manufactured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com