Composite yarn

a technology of composite yarn and yarn, applied in the field of composite yarn, can solve the problems of slow production method, and achieve the effect of excellent mechanical and chemical adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

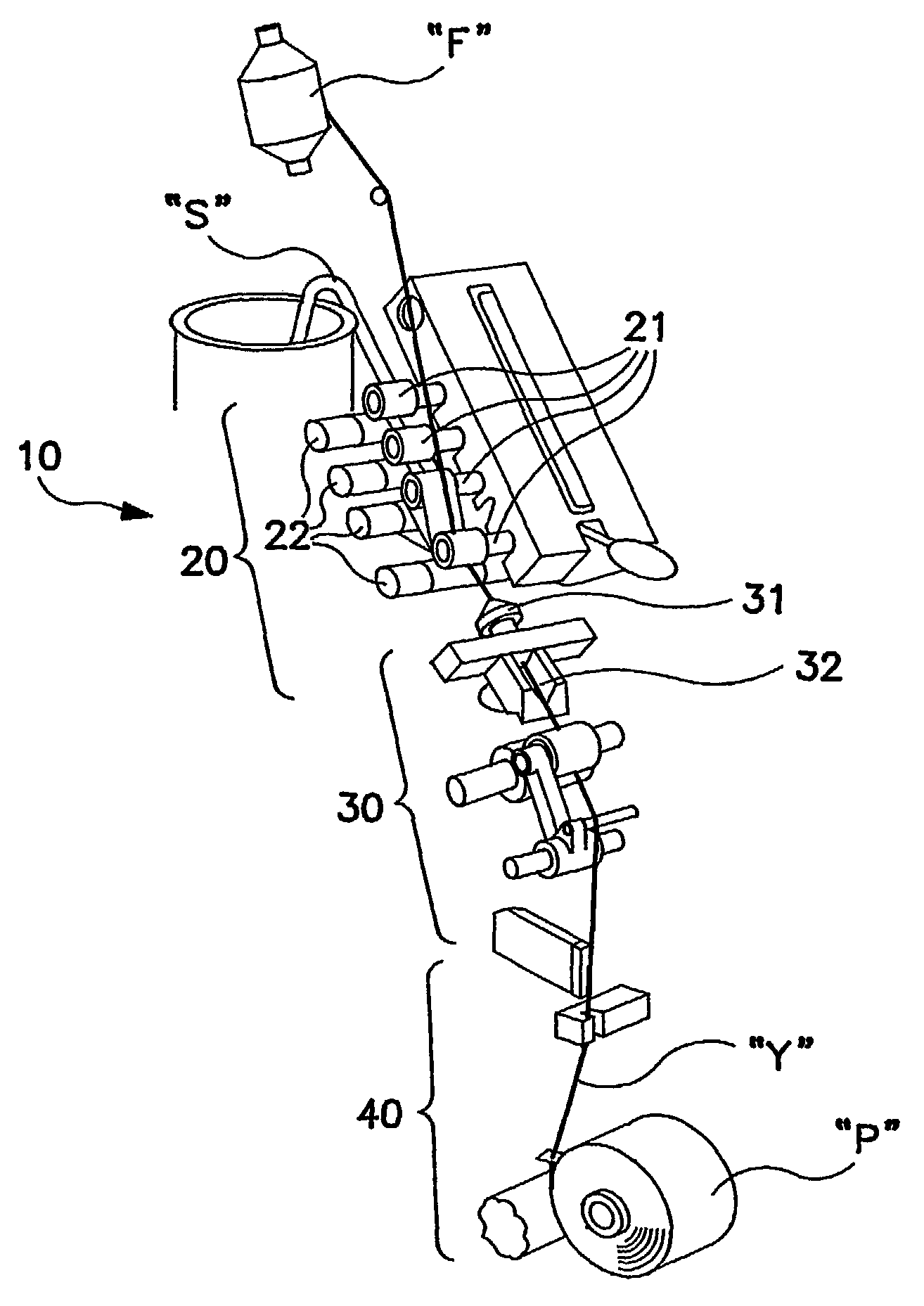

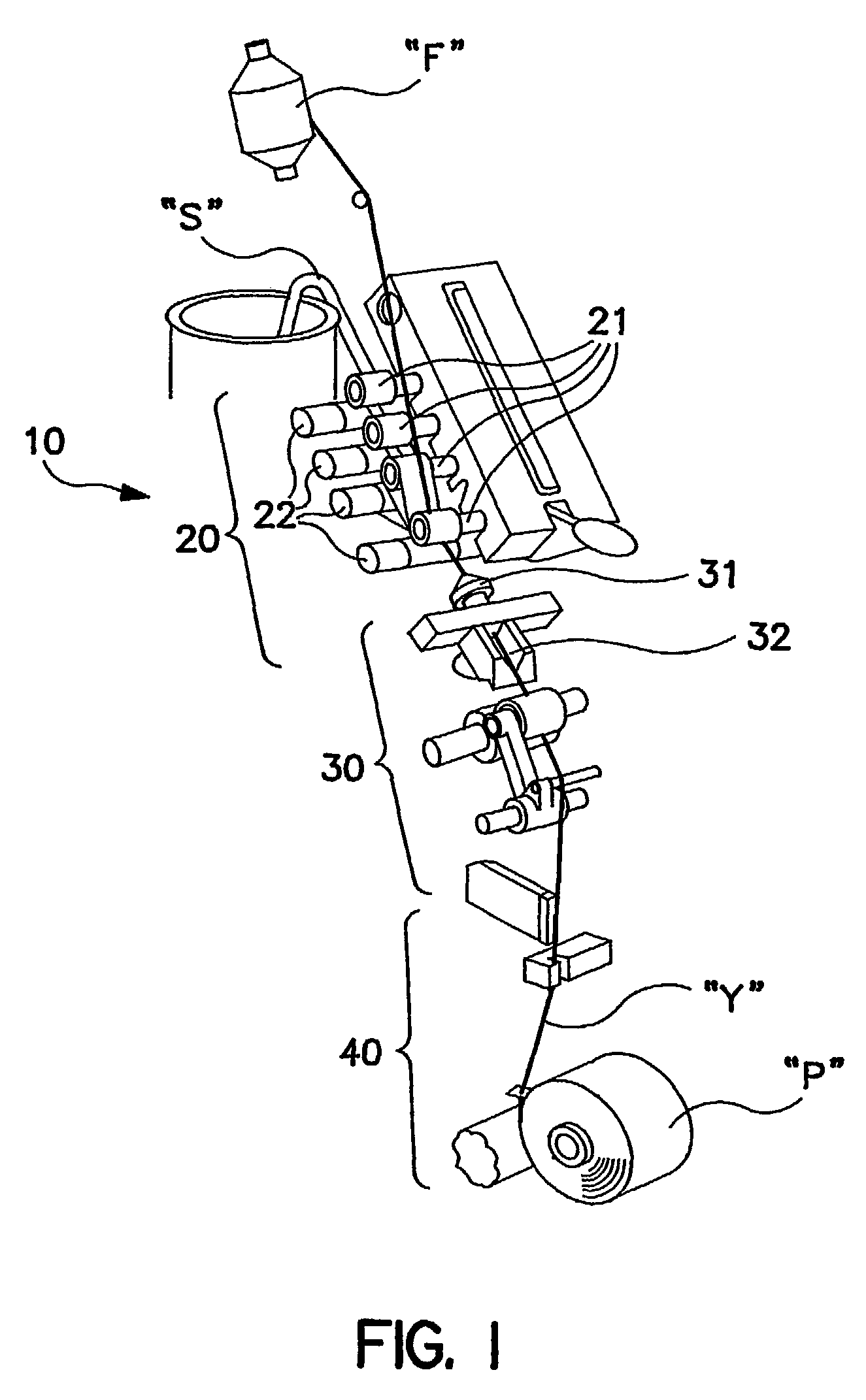

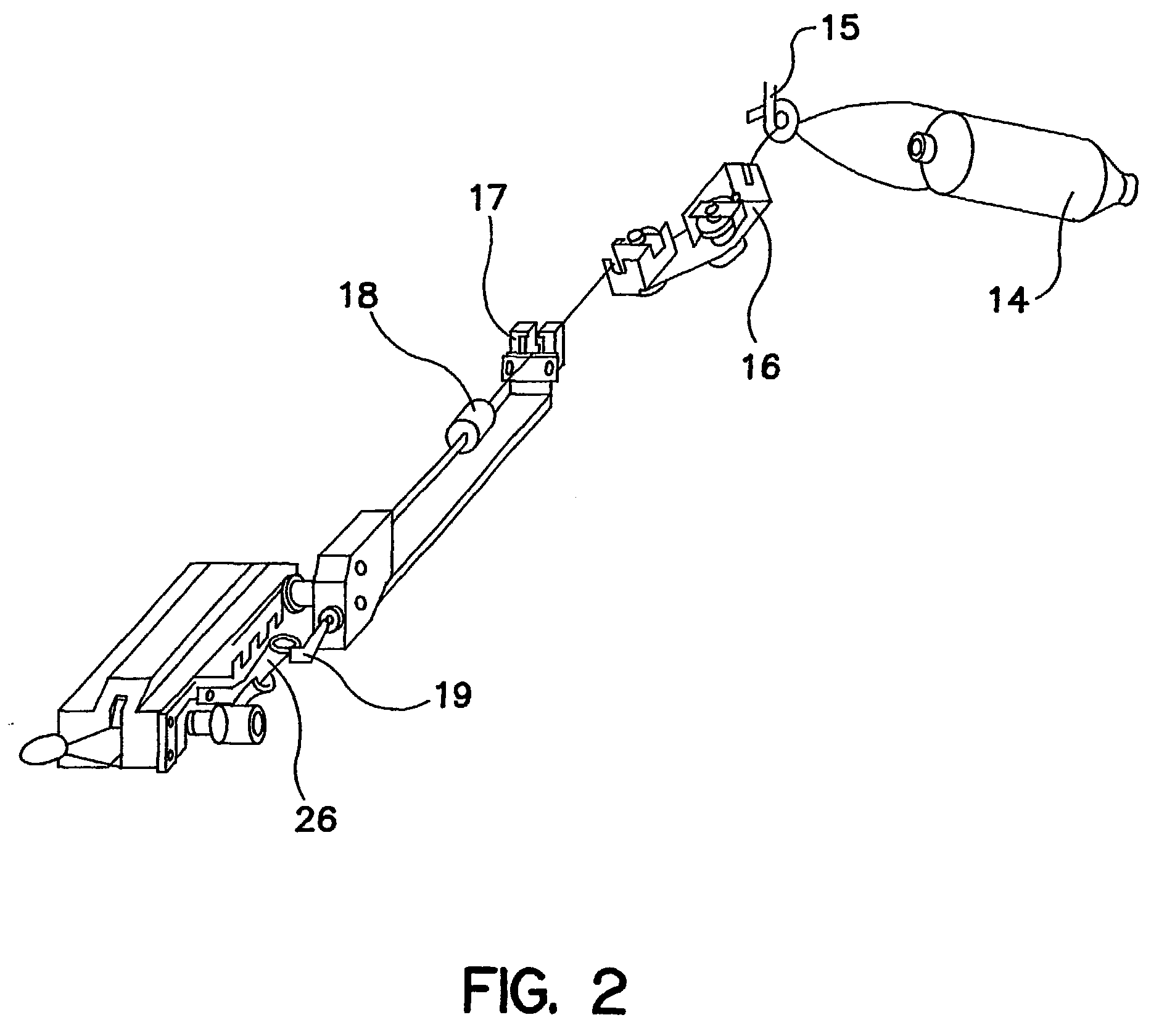

[0038] Referring now specifically to the drawings, a schematic diagram of a Murata MJS Jet Spinner ("MJS") machine which can be configured to produce a yarn according to the present invention is illustrated in FIG. 1 and shown generally at reference numeral 10. Machine 10 includes a drafting zone 20, a spinning zone 30 and a winding zone 40. In conventional jet spinning, a drawn sliver "S" is supplied directly to sets of upper and lower drafting rolls 21, 22, where the sliver is drafted by moving the generally longitudinally-extending fibers past each other in a controlled manner and at controlled rate. The drafted fibers pass through two compressed air nozzles 31, 32 in the spinning zone 30. Compressed air discharged by nozzle 31 whirls about the axis of the nozzle in a direction opposite that discharged by the nozzle 32, thus producing a yarn. The nozzle 32 gathers a group of fibers fed from the drafting rolls 21, 22 by false twisting. Between the front roller in the drafting zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com