Method for enzymatic treatment of textiles such as wool

a technology of enzymology and textiles, applied in the field of enzymology in the treatment of textile goods, can solve the problems of affecting the quality of textile products,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

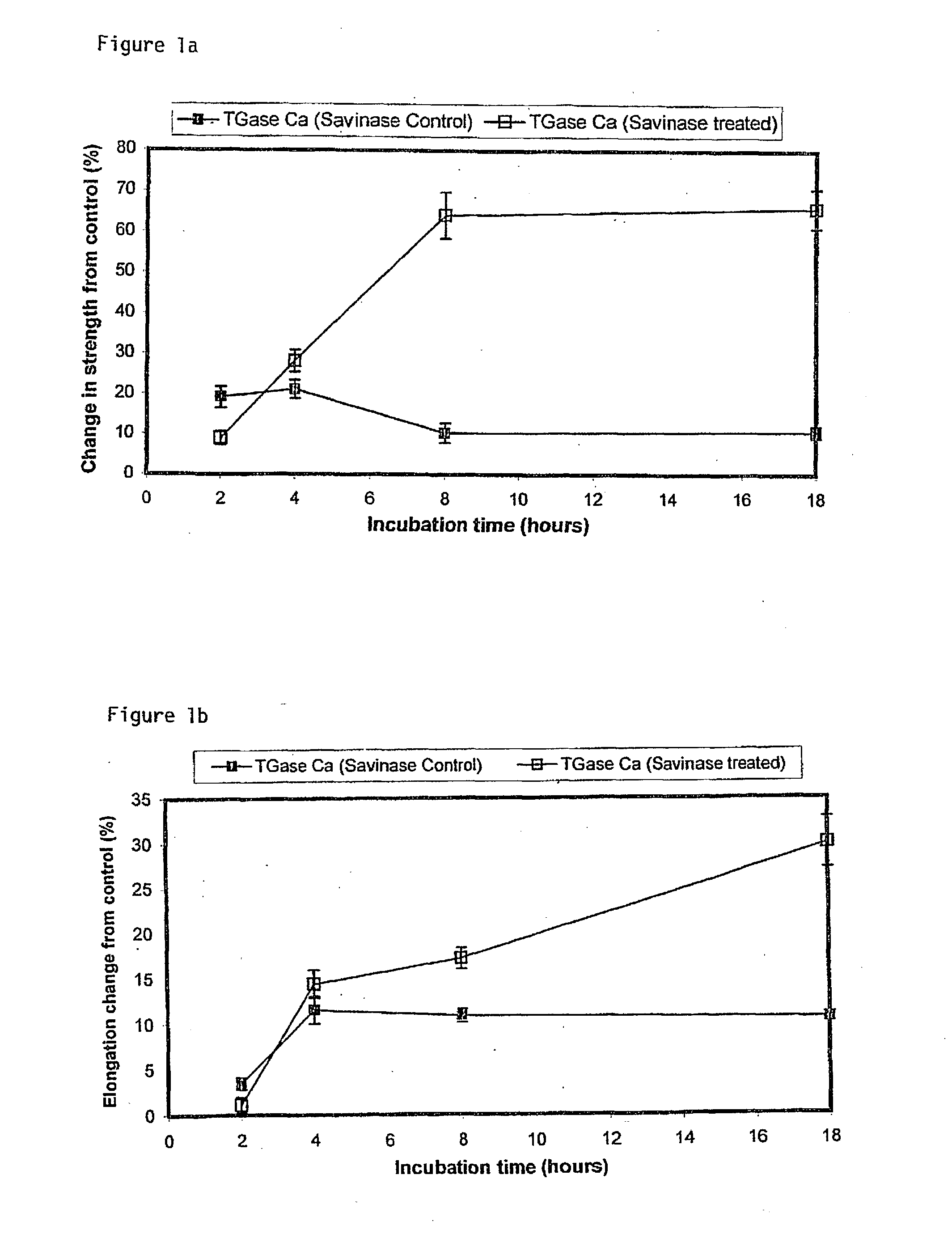

Transglutaminase Crosslinking of Wool--Optimisation of Delivery and Concentration of Enzyme Used

[0084] Samples of 100% wool yarn previously treated with sodium sulphite (as described in Example 1) were treated with Savinase 16L in exactly the same manner as described above. All samples were treated with 5.0, 20.0 and 100.0 .mu.g of guinea pig liver transglutaminase per ml of liquor, and incubated for 6 hours at 37.degree. C. All other treatment parameters were the same as in Example 1. To a second set of samples pretreated exactly in the same manner 1 / 3of the total transglutaminase was added to the treatment bath every two hours (all other treatment parameters were the same). The samples were washed and dried as described in Example 1.

[0085] There was a significant improvement in the strength of all transglutaminase treated yarns compared to the buffer treated controls. These improvements were significantly greater for yarn pretreated with Savinase. In particular, the treatment with...

example 3

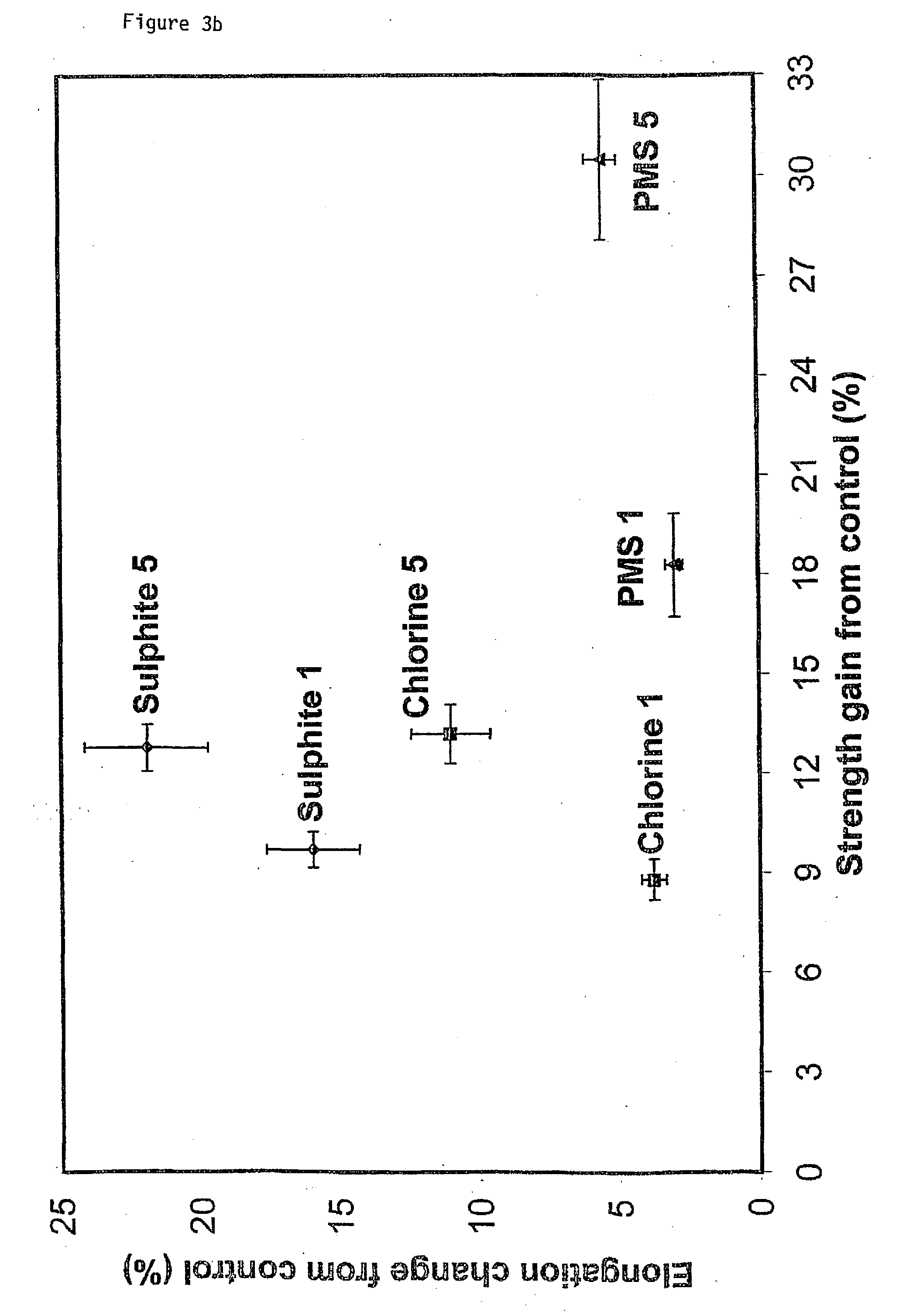

Effect of Different Pretreatments on the Transglutaminase Crosslinking of Wool

[0086] Pretreatment with sodium sulphite and sodium carbonate

[0087] In this example two batches of yarn samples were first treated with a) 0.5 g / L of sodium carbonate and 1 g / l of a non-ionic detergent and b) 5.0 g / l of sodium sulphite and 1 g / L of a non-ionic detergent both at a liquor to fibre ratio of 250 ml / g for 30 minutes at 60.degree. C. Samples from a) and b) were then submitted to a Savinase treatment as described in Example 1. The proteolytic reaction was stopped by washing the samples with a non-ionic detergent at pH 5 and then in hot water at 80.degree. C. for 15 minutes. Finally, the samples were rinsed before submitted to further treatment. As a control to the protease treatment, yarn samples from a) and b) were also treated with buffer only.

[0088] The four resulting sets of yarn samples were then treated with 1.0 .mu.g of transglutaminase per ml of liquor, and incubated for a period of time ...

example 4

Transglutaminase Treatments Prior to Protease Treatment

[0095] This experiment was carded using the same procedure as described in Example 1, except that in one batch of samples the protease treatment was carried out prior to the transglutaminase treatment and on the second batch the protease treatment was carried out after the transglutaminase treatment. In both yarn sample batches the concentration of Savinase 16 L were carried out as described in Example 1. All samples were treated with 1.0 .mu.g transglutaminase was per ml of liquor, and incubated for 18 hours at 37.degree. C. All other treatment parameters were the same as described in Example 1. The samples were washed and dried as described in Example 1.

[0096] The results (see FIG. 4) indicate that the transglutaminase treatment prior to the Savinase treatment not only reduced the loss of strength caused by the subsequent protease treatment (comparing to the Savinase / protease treatment) but also increased the strength of the y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com