Two-layer imageable composition including non-volatile acid in bottom layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples c1 , 1 and 2

Examples C1, 1 and 2

[0139] Coating formulations included solutions of the components described in table 1 in 1-methoxypropan-2-ol / acetone 92:8 (w:w). Plates were prepared by coating the formulations onto the aluminum substrate by means of a whirl coater. The formulation concentrations were selected to provide dry films having a coating weight of 120 mg / ft. The coated plates were dried at 100.degree. C. for 90 seconds. The film weights were measured after thorough air drying over several days.

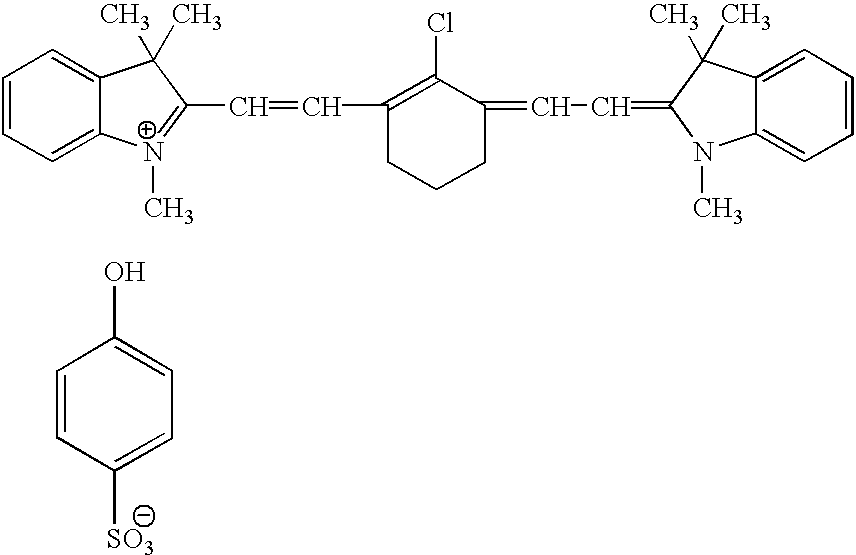

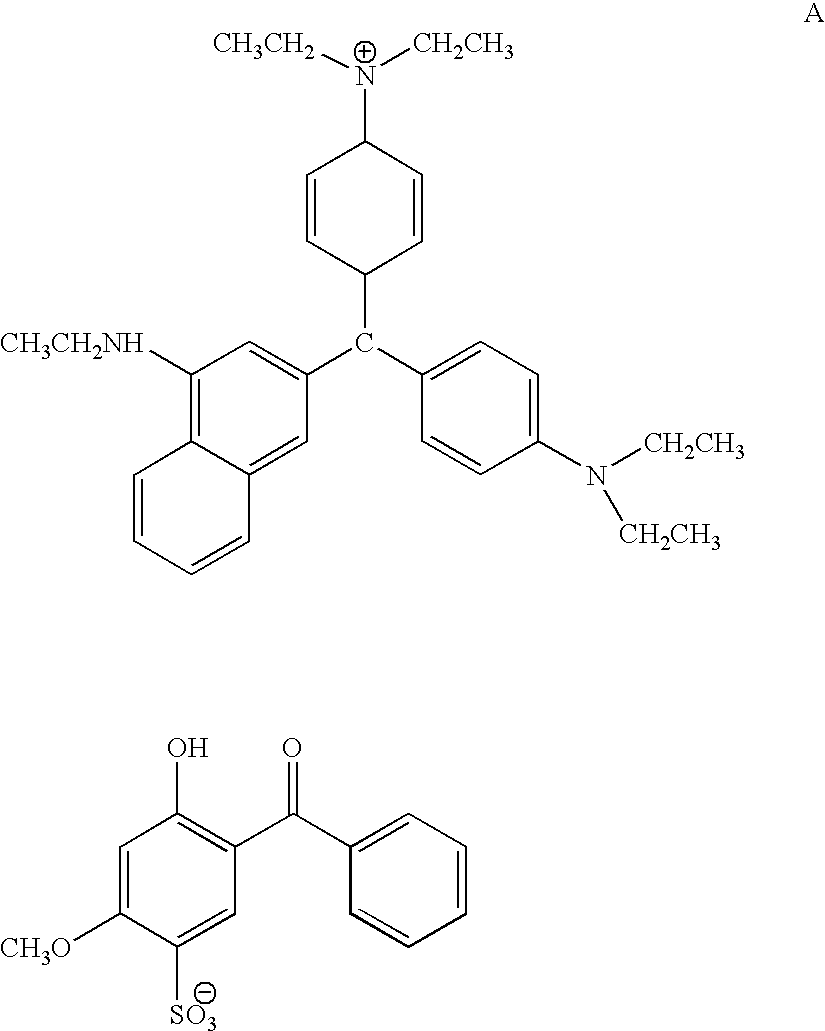

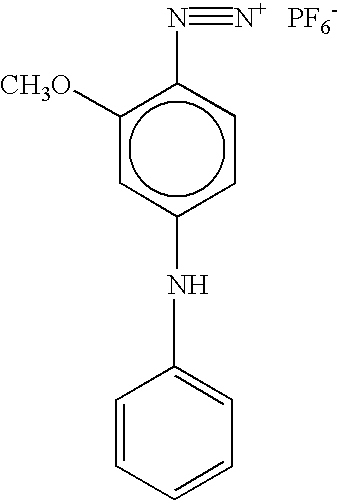

1 TABLE 1 Example C1 1 2 Component Parts by Weight Resin A 28.2 28.2 28.0 Resin B 48.3 48.3 47.9 Acid Generator A 7.5 7.5 7.4 IR Dye A 8.6 8.6 8.5 Terephthaldehyde 6.5 6.5 6.4 Blue Dye A 0.9 0.9 Blue Dye B 0.9 0.9

Ascertaining Fog Point

[0140] Unimaged plate samples were placed in a heavy duty Wisconsin oven (conveyor speed=2.5 feet / min) starting at a temperature of 275.degree. F. and decreasing by 5.degree. F. intervals. After processing in a Mercury Mark V processor (containing 9005+developer at...

examples c2 and 3

[0149] Coating formulations included solutions of the components described in Table 4 in 1-methoxypropan-2-ol / acetone 92:8 (w:w).

4 TABLE 4 Example C2 3 Component Parts by Weight Resin A 28.6 28.6 Resin B 48.4 48.4 Acid Generator A 7.5 7.5 IR Dye A 7.8 7.8 Terephthaldehyde 6.5 6.5 Blue Dye A 1.2 Blue Dye B 1.2

[0150] Plates were prepared by coating the formulations onto the aluminum substrate by means of a whirl coater. The formulation concentrations were selected to provide dry films having a coating weight of 120 mg / ft. The coated plates were dried at 100.degree. C. for 90 seconds. The film weights were measured after thorough air drying over several days.

Ascertaining Fog Point

[0151] Unimaged plate samples were placed in a heavy duty Wisconsin oven (conveyor speed=2.5 feet / min) starting at a temperature of 275.degree. F. and decreasing by 5.degree. F. intervals.

[0152] After processing in a Mercury Mark V processor (containing 9005+ developer at 25.degree. C., processing speed 740 mm...

examples 4 to 8

[0155] Coating formulations included solutions of the components described in table 6 in 1-methoxypropan-2-ol / acetone 92:8 (w:w). Plates were prepared by coating the formulations onto the aluminum substrate by means of a whirl coater. The formulation concentrations were selected to provide dry films having a coating weight of 120 mg / ft. The coated plates were dried at 100.degree. C. for 90 seconds. The film weights were measured after thorough air drying over several days.

6 TABLE 6 Example 4 5 6 7 8 Component Parts by Weight Resin A 28.48 28.47 28.44 28.42 28.41 Resin B 48.60 48.55 48.51 48.49 48.46 Acid Generator A 7.54 7.53 7.53 7.52 7.52 IR Dye A 7.88 7.87 7.86 7.86 7.85 Terephthaldehyde 6.54 6.53 6.52 6.52 6.52 Blue Dye B 0.96 1.05 1.14 1.19 1.24

Thermal Exposure

[0156] Plate samples were then imaged on the Creo Trendsetter at 55,64, 77,96,129 and 194 mJ / cm.sup.-2, using an internal solid image pattern (100% exposure). They were then pre-heated in the heavy duty Wisconsin oven (co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Crosslinkable | aaaaa | aaaaa |

| Volatility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com