Method for preparing graphite at ultra-low temperature

A technology of expanded graphite and ultra-low temperature, which is applied in the field of expanded graphite, can solve the problems of restricting the large-scale production of expanded graphite and high heat treatment temperature, and achieve the effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

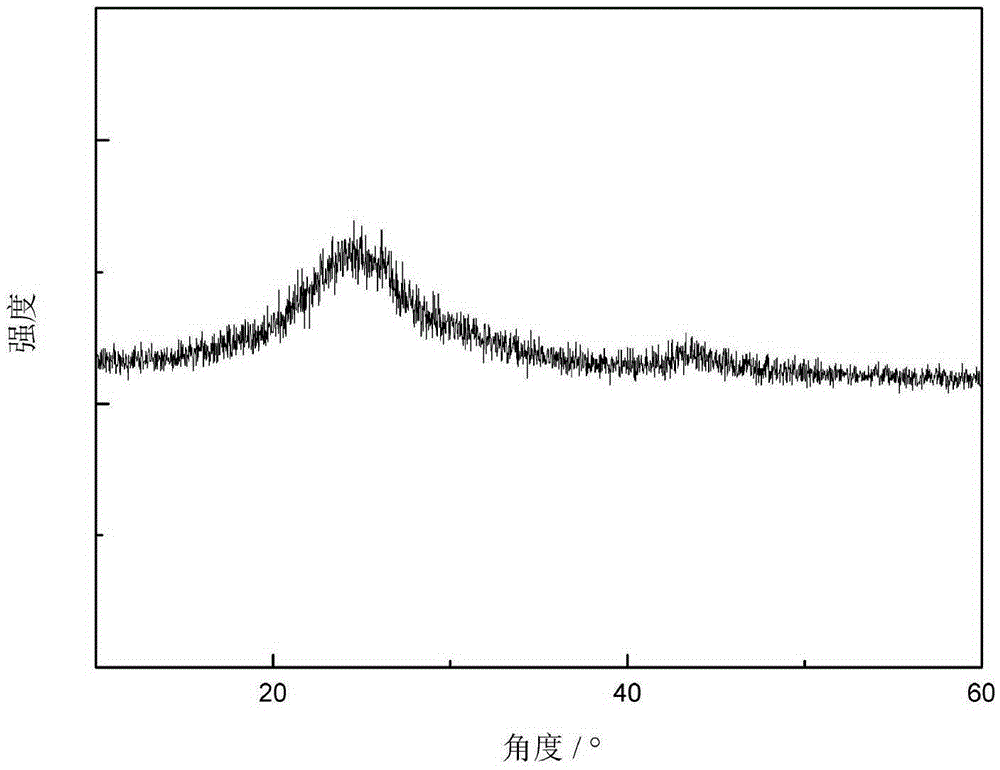

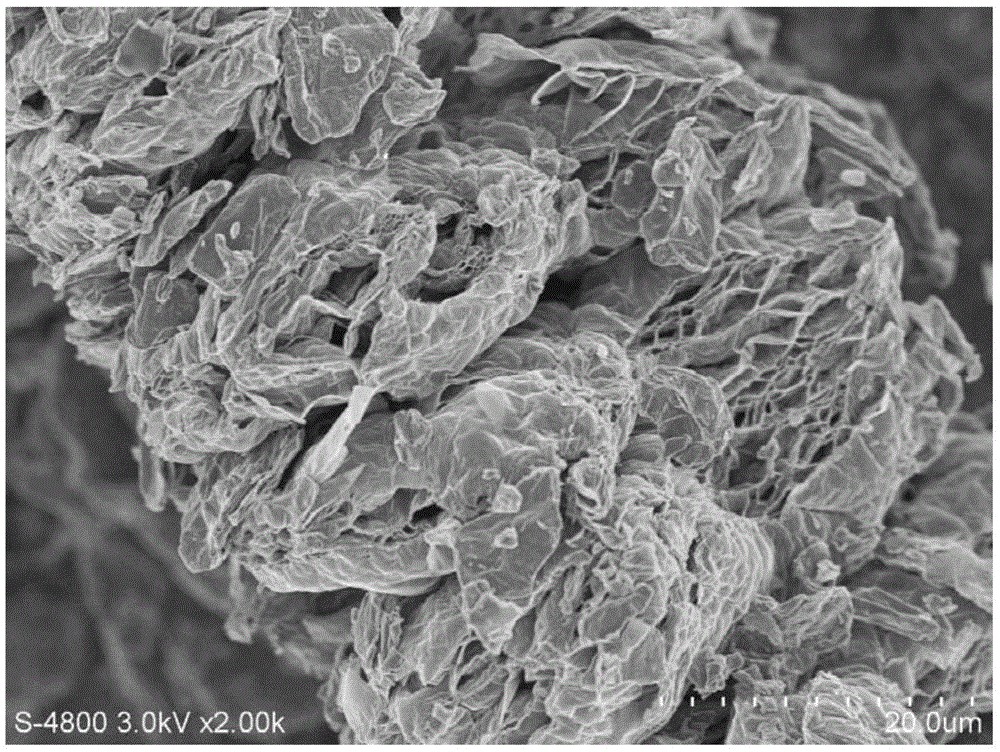

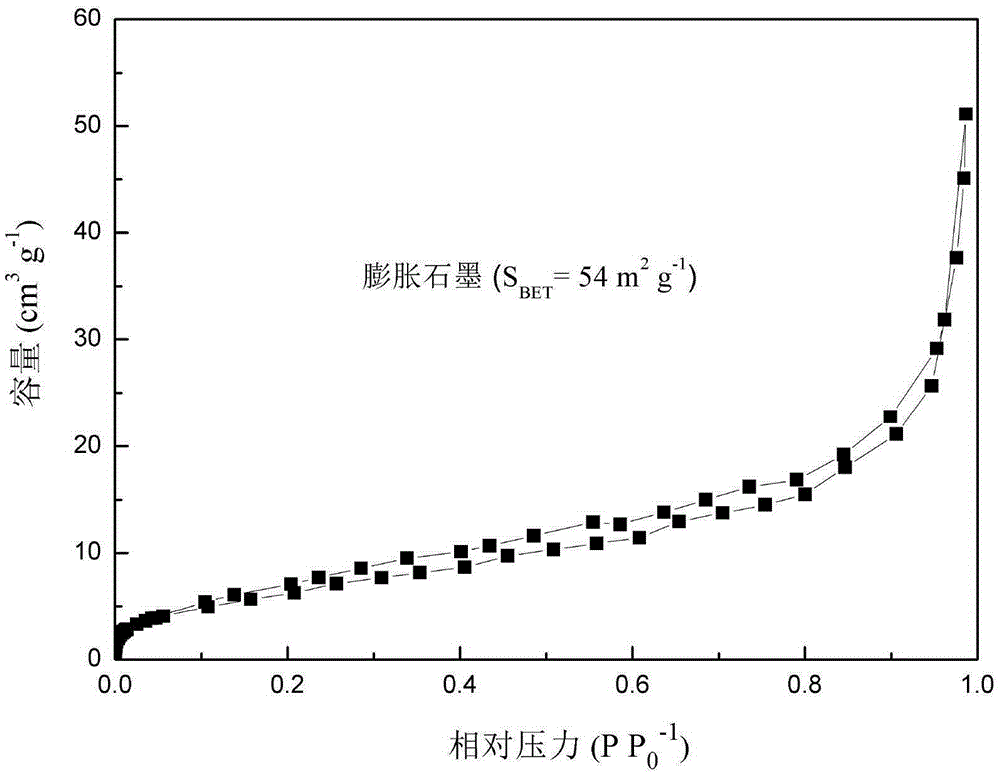

Embodiment 1

[0023] The invention discloses a method for preparing expanded graphite at ultra-low temperature. The flake graphite is used as a raw material, and the graphite oxide is obtained by using the Hummers method. Soak the wet (undried) graphite oxide in an aqueous solution of sulfuric acid (concentration 3%) to acidify, separate the acidified graphite oxide from the acid solution, and place the wet and acidified graphite oxide at 70°C The preliminary product is directly obtained after heat treatment under the ultra-low temperature condition, and the expanded graphite is obtained after washing and purification.

Embodiment 2

[0025] The invention discloses a method for preparing expanded graphite at ultra-low temperature. Artificial graphite is used as a raw material to obtain graphite oxide by Hummers method. Soak the wet (undried) graphite oxide in an aqueous solution of sulfuric acid (50% concentration) for acidification, separate the acidified graphite oxide from the acid solution, and place the wet and acidified graphite oxide at 50°C The preliminary product is directly obtained after heat treatment under the ultra-low temperature condition, and the expanded graphite is obtained after washing and purification.

Embodiment 3

[0027] The invention discloses a method for preparing expanded graphite at ultra-low temperature, using natural graphite as a raw material, and obtaining graphite oxide by Hummers method. Soak wet (undried) graphite oxide in an aqueous solution of perchloric acid (concentration 10%) to carry out acidification treatment, separate acidified graphite oxide from the acid solution, and wet and acidified graphite oxide in The primary product is directly obtained after heat treatment at an ultra-low temperature of 110°C, and expanded graphite is obtained after washing and purification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com