Apparatus for advancing streams of particles of smokable material

a technology of smokable material and apparatus, which is applied in the field of conveyors, can solve the problems of affecting the useful life of the conveyor, affecting the consistency and/or configuration of the growing tobacco stream, and the stationary walls which come in contact with tobacco particles are subject to extensive wear, and achieves a low resistance to sliding of tobacco particles and pronounced resistance to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

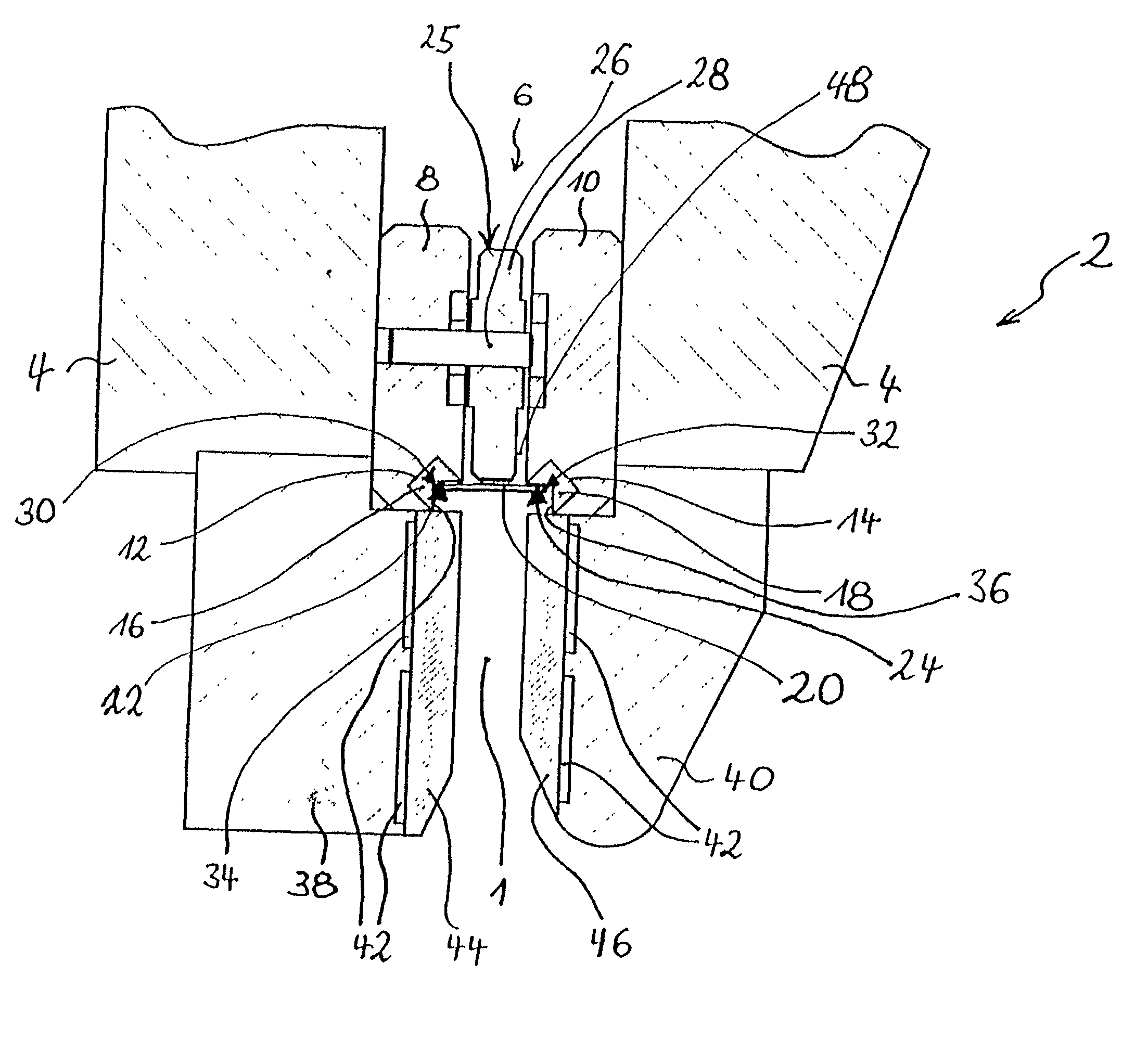

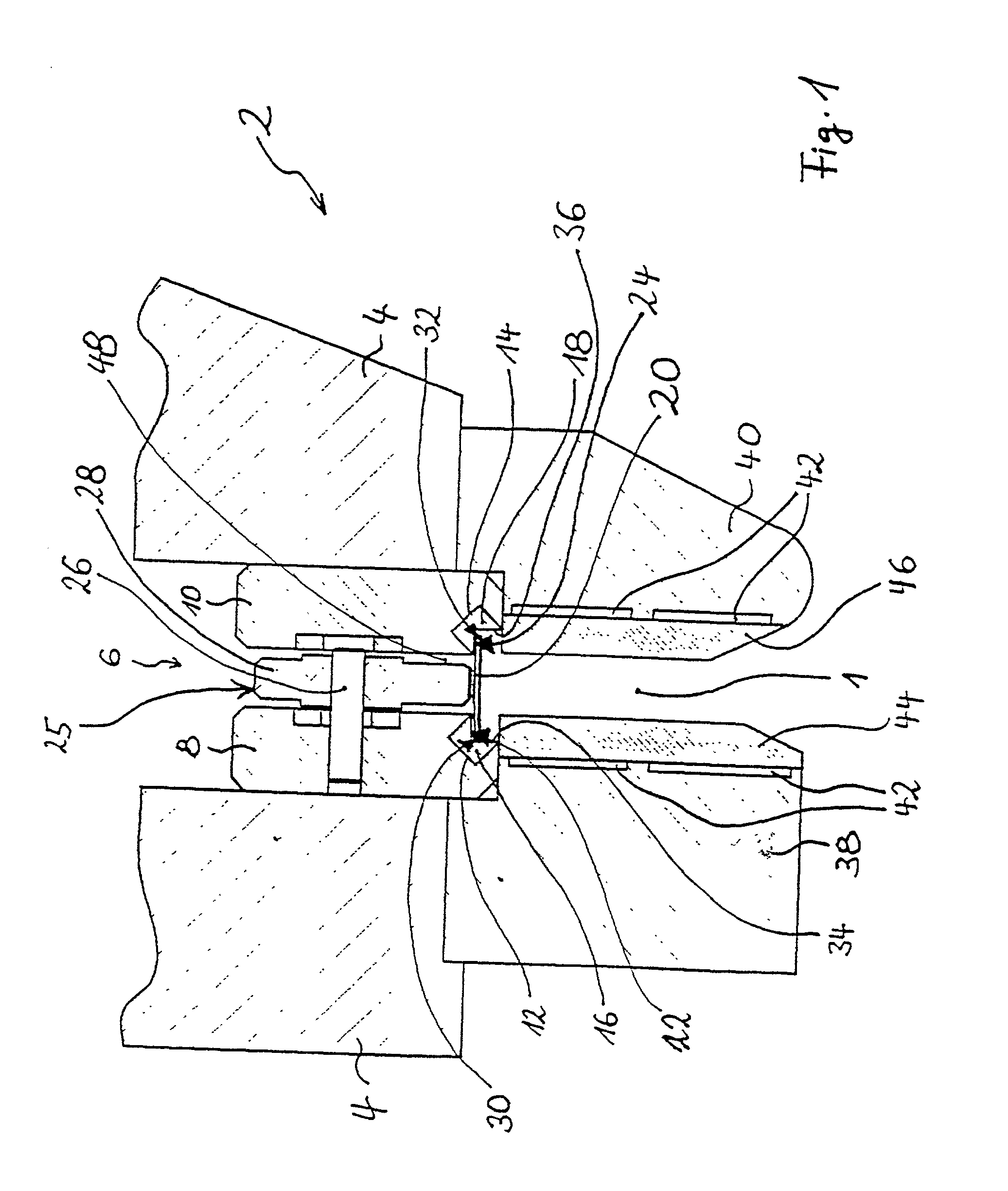

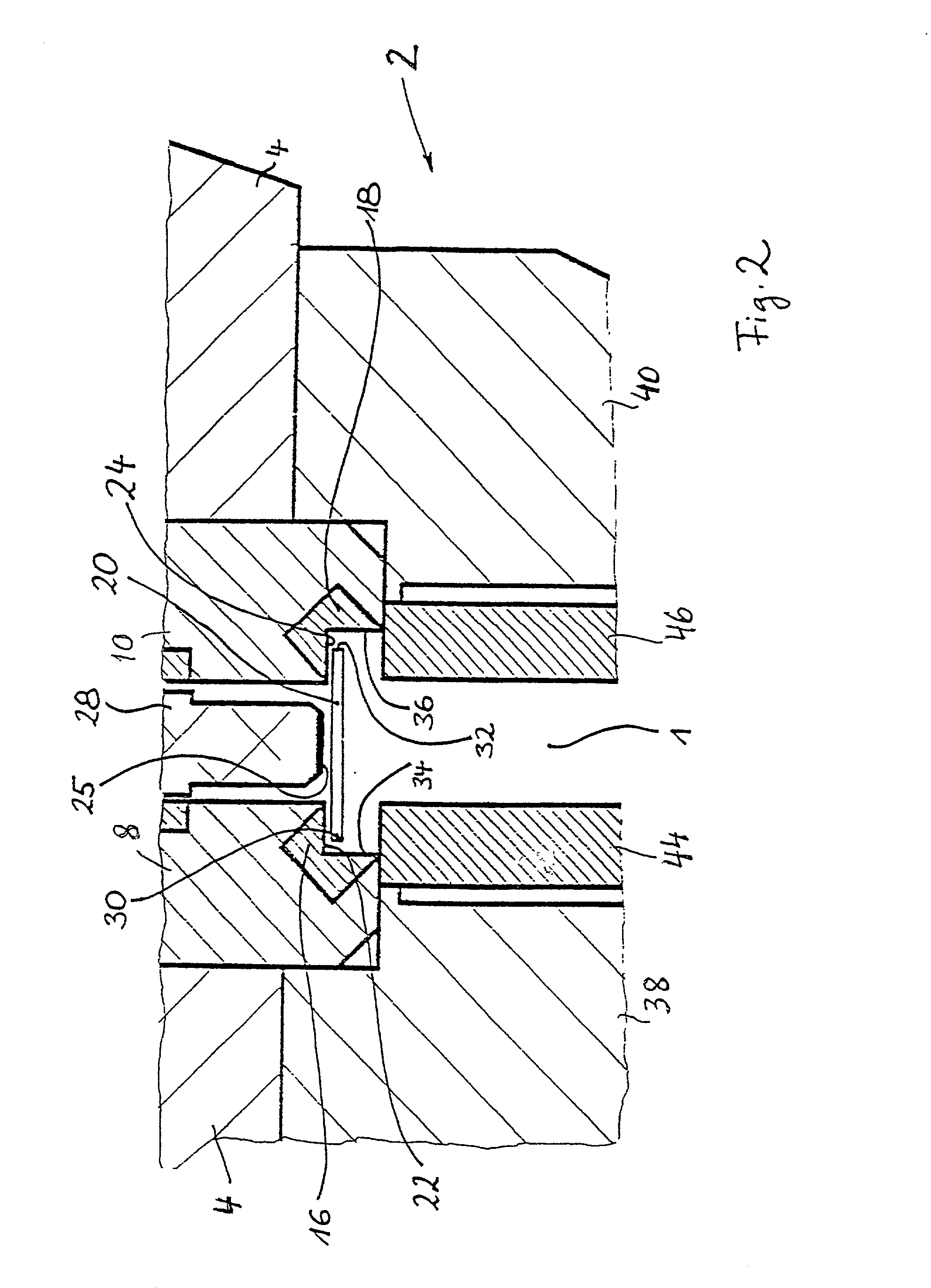

[0023] FIG. 1 shows a portion of a conveyor 2 which embodies one form of the present invention and includes an elongated channel or duct defining an elongated path 1 for reception and advancement of successive increments of a continuous ascending shower of tobacco particles forming a stream at the underside of the lower reach or stretch 20 of an endless foraminous belt being driven in a manner not shown in the drawings to advance tobacco particles in a direction at right angles to the plane of FIG. 1. Reference may be had, for example, to FIG. 3 of the aforementioned U.S. Pat. No. 5,072,742 to Heitmann which shows a conventional conveyor having an endless foraminous belt 61 including a lower reach located below the perforated bottom wall 59 of a suction chamber 61 and above the open upper end of a tubular guide 52 for an ascending shower of tobacco particles. The ascending shower of tobacco particles gathers into a continuous stream which is advanced along an at last substantially h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com