Decorative sheet and processes for the production of sheets

a technology of decorative sheets and sheets, applied in the field of decorative sheets, can solve the problems of increased thickness of sheets, severe swelling of sheets, and inability to maintain sheets of this typ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

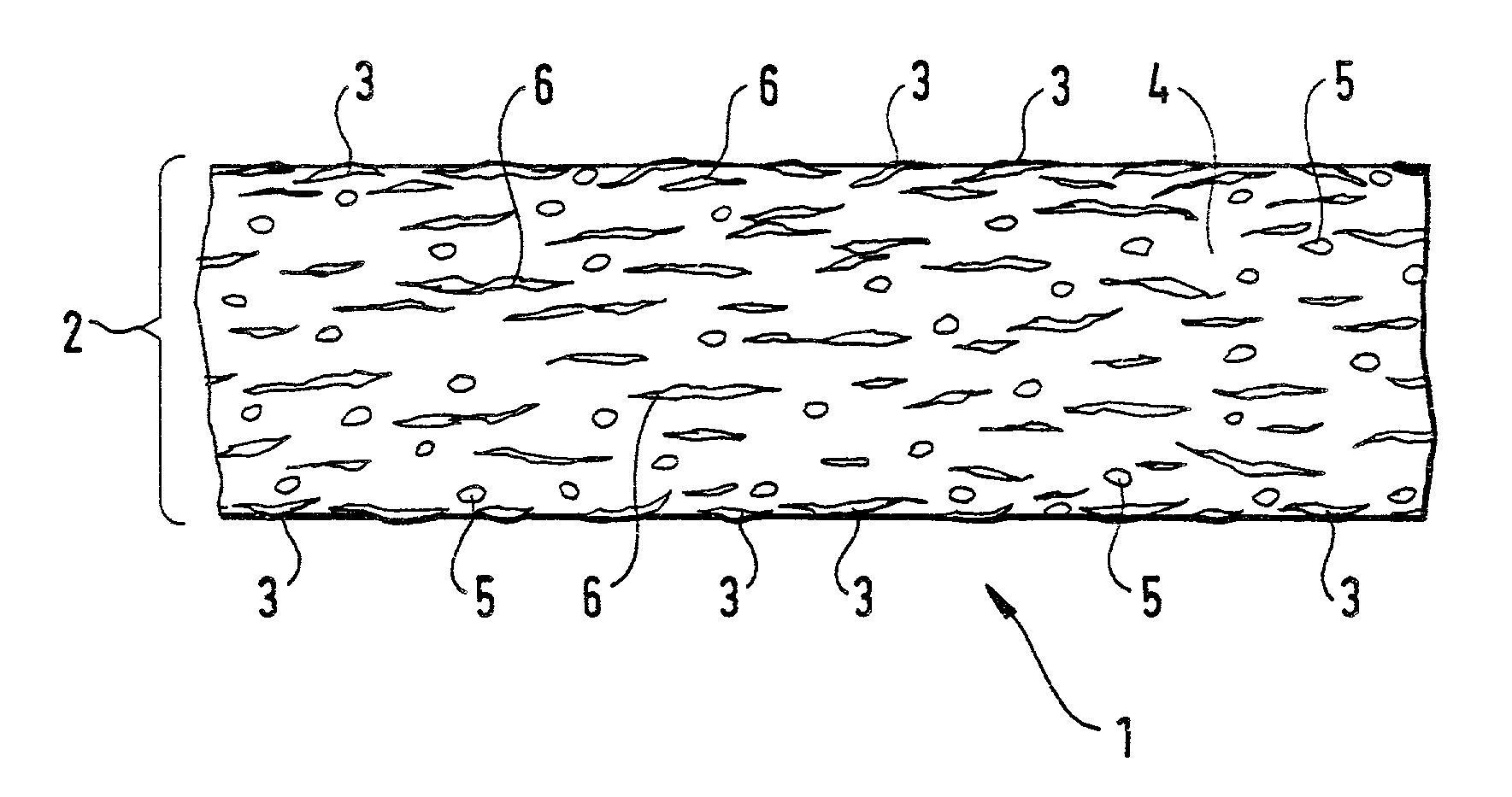

Image

Examples

example 2

[0024] Sheets made from wood fibers, from a phenolic resin and from 1 to 5% by weight of titanium dioxide, based on the total weight of resin-treated fibers and pigments, have a pale color similar to that of spruce. After changes on weathering, the color of the sheets is like that of weathered American cherry and / or European oak.

example 3

[0025] Sheets made from wood fibers, from a phenolic resin, and also from 1 to 5% by weight of titanium oxide and from 0.05 to 1% by weight of iron oxide red, in each case based on the total weight of resin-treated fibers and pigments, have a color like that of American cherry. After changes on weathering, the color of the sheets is like that of weathered meranti wood.

[0026] Sheets of this type are used for external cladding of buildings, for example in curtain facades, as panels screening walls or roofs, as parapet panels or apron panels, or as facings for balconies. This list is certainly not comprehensive, and does not place any restriction on possibilities for using the sheets of the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| lengths | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com