Ball grid array packaging structure

A ball grid array and packaging structure technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of additional cost of bottom glue, internal chip damage, cracking of the corners and edges of the packaging structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment is used below to illustrate the package structure of the ball grid array according to an embodiment of the present invention.

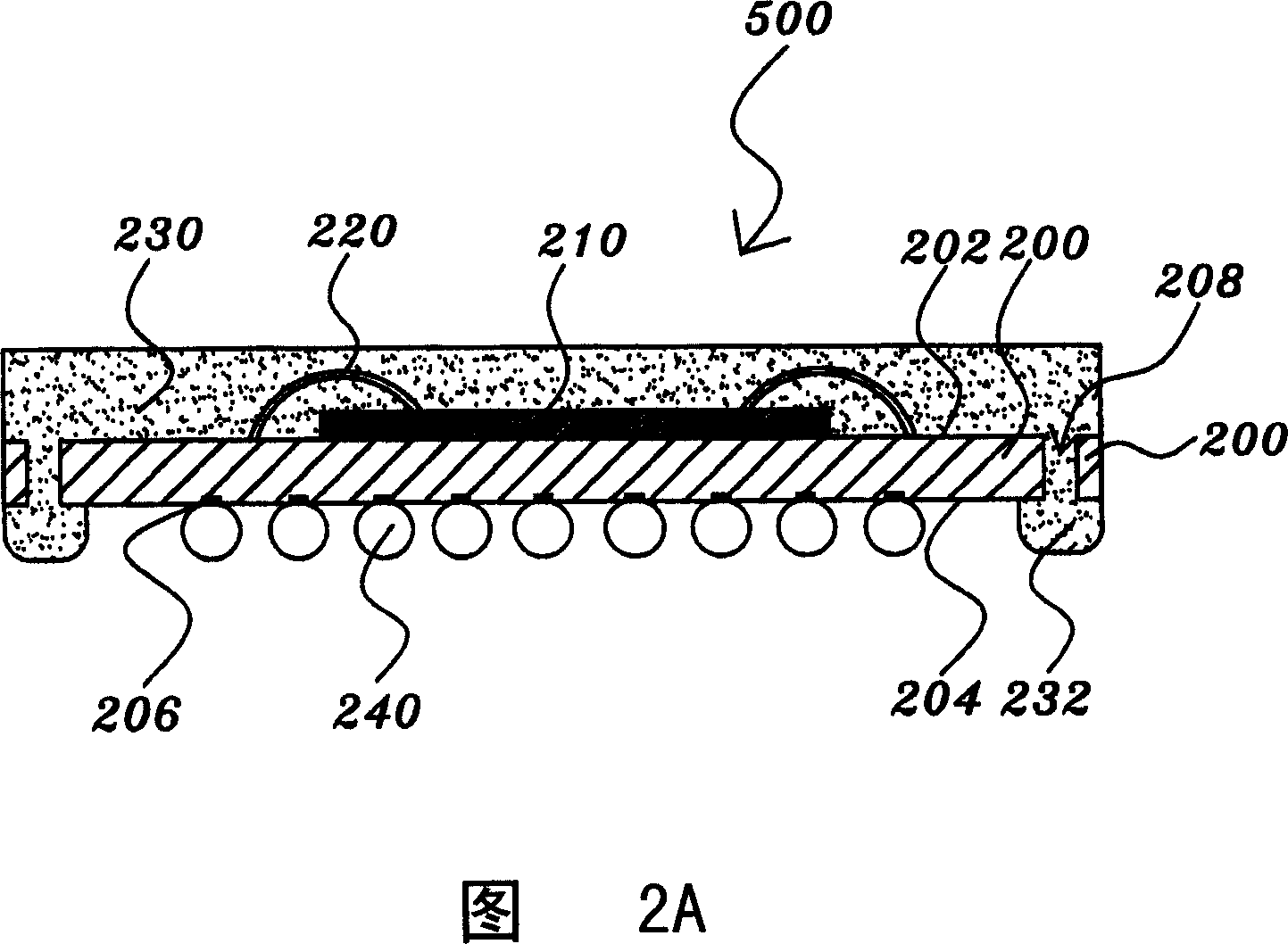

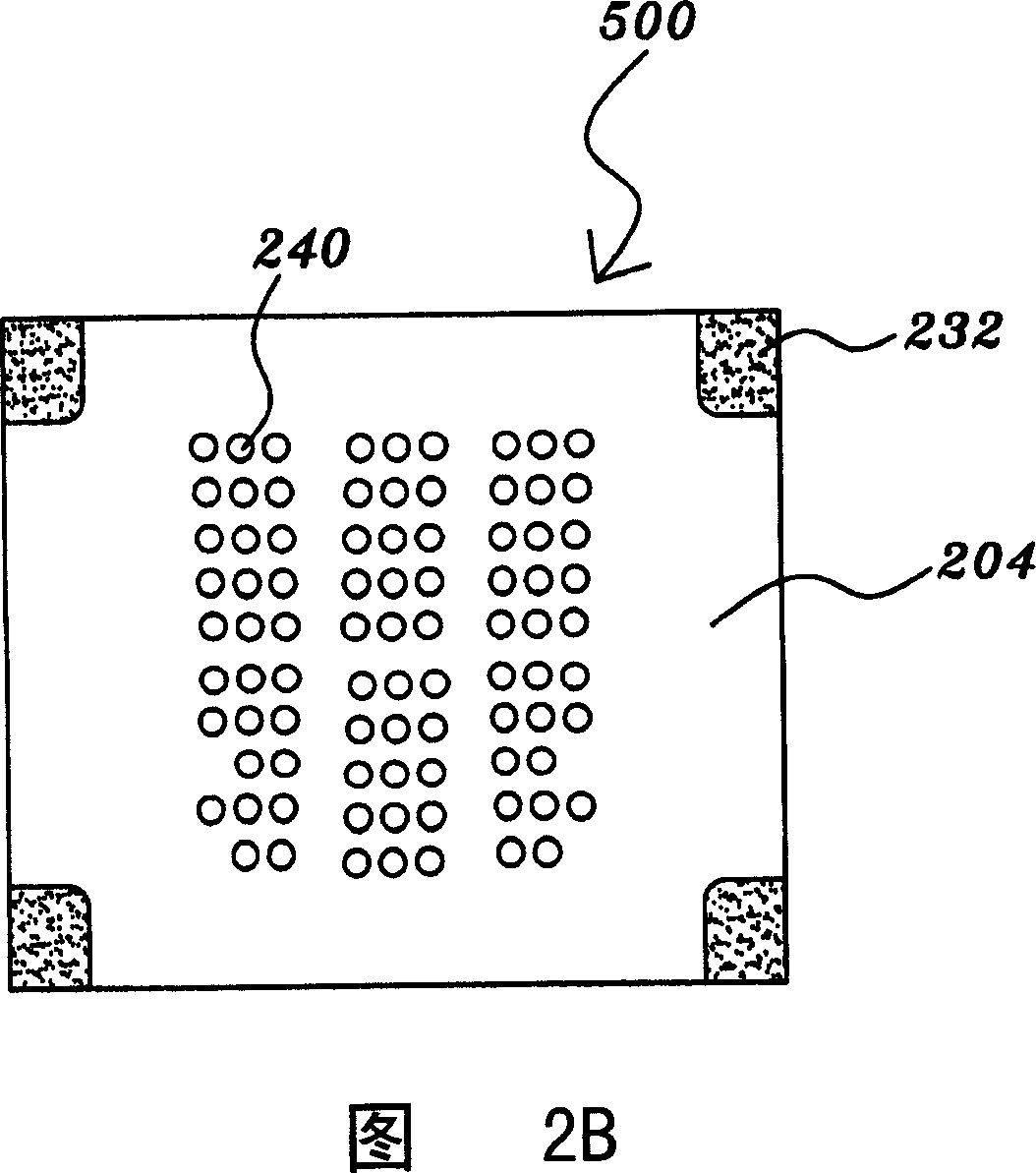

[0017] First, please refer to FIGS. 2A and 2B . FIG. 2A is a schematic cross-sectional view of a ball grid array package structure according to an embodiment of the present invention, and FIG. 2B is a schematic bottom view of the embodiment. As shown in the figure, in this embodiment, the ball grid array package structure 500 includes a substrate 200, for example, made of polyimide (polyimide), glass, aluminum oxide, beryllium oxide or elastomer (elastomer) material, The substrate 200 has an upper surface 202 and a lower surface 204 opposite to the upper surface 202, wherein the lower surface 204 is provided with a plurality of electrical contacts 206, and a chip 210 is arranged on the upper surface 202 of the substrate 200, and the chip 210 To electrically connect the above-mentioned plurality of electrical connection po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com