Preparing process of Ru(II) polypyridine complex

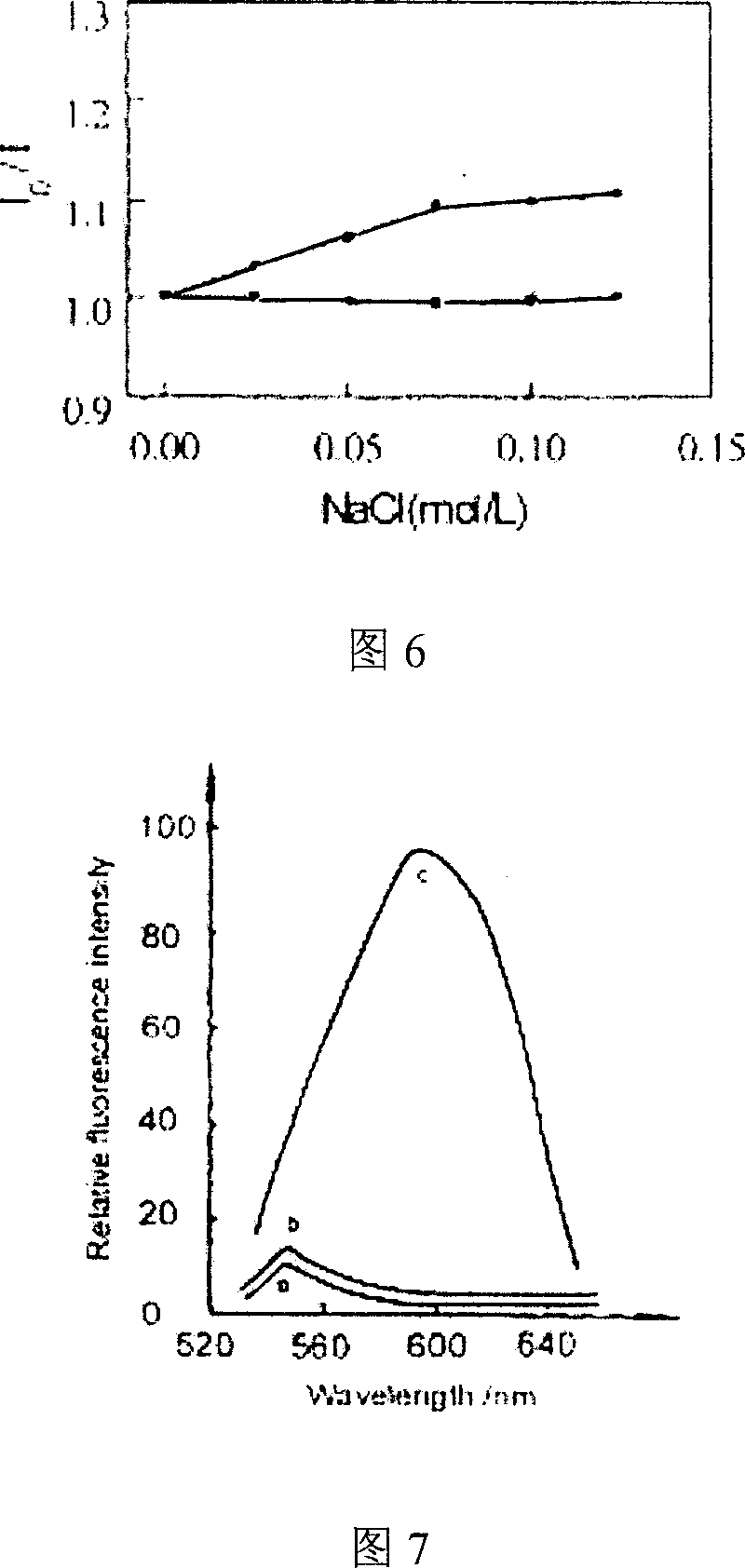

A polypyridine and complex technology, which is applied in the field of preparation of ruthenium polypyridine complexes, can solve the problems of weak fluorescence enhancement, limitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Ruthenium (II) polypyridine complex preparation:

[0025] 1. Add 15g o-phenanthroline and 8.0g sodium bromide successively in a 250mL flask, add 90mL concentrated sulfuric acid and 45mL concentrated nitric acid while stirring, heat (the temperature is controlled at 120°C or 150°C) and reflux for 50min, and cool to 20 or After 25°C, neutralize with 0% sodium hydroxide, extract the filtered filtrate with dichloromethane, heat the extract to 100°C, evaporate to dryness and recrystallize with methanol to obtain 1,10-phenanthroline-5 , 6-diquinone product;

[0026] 2. Add 0.5g of 1,10-phenanthroline-5,6-diquinone and o-phenylenediamine to a 250mL flask respectively, then add 100mL of ethanol, heat (the temperature is controlled at 100°C or 110°C) to reflux for 20min, and cool After reaching 15 or 20°C, add 10ml of water to produce a yellow milky precipitate, filter and recrystallize with a mixture of ethanol and water (3:1, v / v) to obtain yellow needle-like cr...

Embodiment 2

[0029] Embodiment 2: Ruthenium (II) polypyridine complex preparation:

[0030] 1. Add 15g o-phenanthroline and 8.0g sodium bromide successively in a 250mL flask, add 90mL concentrated sulfuric acid and 45mL concentrated nitric acid while stirring, heat (the temperature is controlled at 120°C or 150°C) and reflux for 50min, and cool to 20 or After 25°C, neutralize with 30% sodium hydroxide, extract the filtered filtrate with dichloromethane, heat the extract to 100°C, evaporate to dryness and recrystallize with methanol to obtain 1,10-phenanthroline-5 , 6-diquinone product;

[0031] 2. Add 0.5g 1,10-phenanthroline-5,6-diquinone and 4,5-dimethyl-o-phenylenediamine respectively in a 250mL flask, then add 100mL ethanol and heat (the temperature is controlled at 110°C or 130°C) for reflux for 20min, cooled to 15 or 20°C, adding 10ml of water to produce a yellow milky precipitate, filtered and recrystallized with a mixture of ethanol and water (3:1, v / v) to obtain a yellow needle ...

Embodiment 3

[0034] Embodiment 3: Ruthenium (II) polypyridine complex preparation:

[0035] 1. Add 15g o-phenanthroline and 8.0g sodium bromide successively into a 250mL flask, add 90mL concentrated sulfuric acid and 45mL concentrated nitric acid while stirring, heat (the temperature is controlled at 120°C or 150°C) and reflux for 50min, and cool to 20°C Or after 25°C, neutralize with 30% sodium hydroxide, extract the filtered filtrate with dichloromethane, heat the extract to 100°C, evaporate to dryness and recrystallize with methanol to obtain 1,10-phenanthroline- 5,6-Diquinone product;

[0036] 2. Add 0.5g of 1,10-phenanthroline-5,6-diquinone and o-phenylenediamine to a 250mL flask respectively, then add 100mL of ethanol, heat (the temperature is controlled at 100°C or 110°C) to reflux for 20min, and cool After reaching 15°C or 20°C, add 10ml of water to produce a yellow milky precipitate, filter and recrystallize with a mixture of ethanol and water (3:1, v / v) to obtain yellow needle-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com