Bubbling reaction cleaning device and method

A technology for cleaning devices and air bubbles, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., which can solve problems such as large water consumption, environmental protection, and inability to handle metal layer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

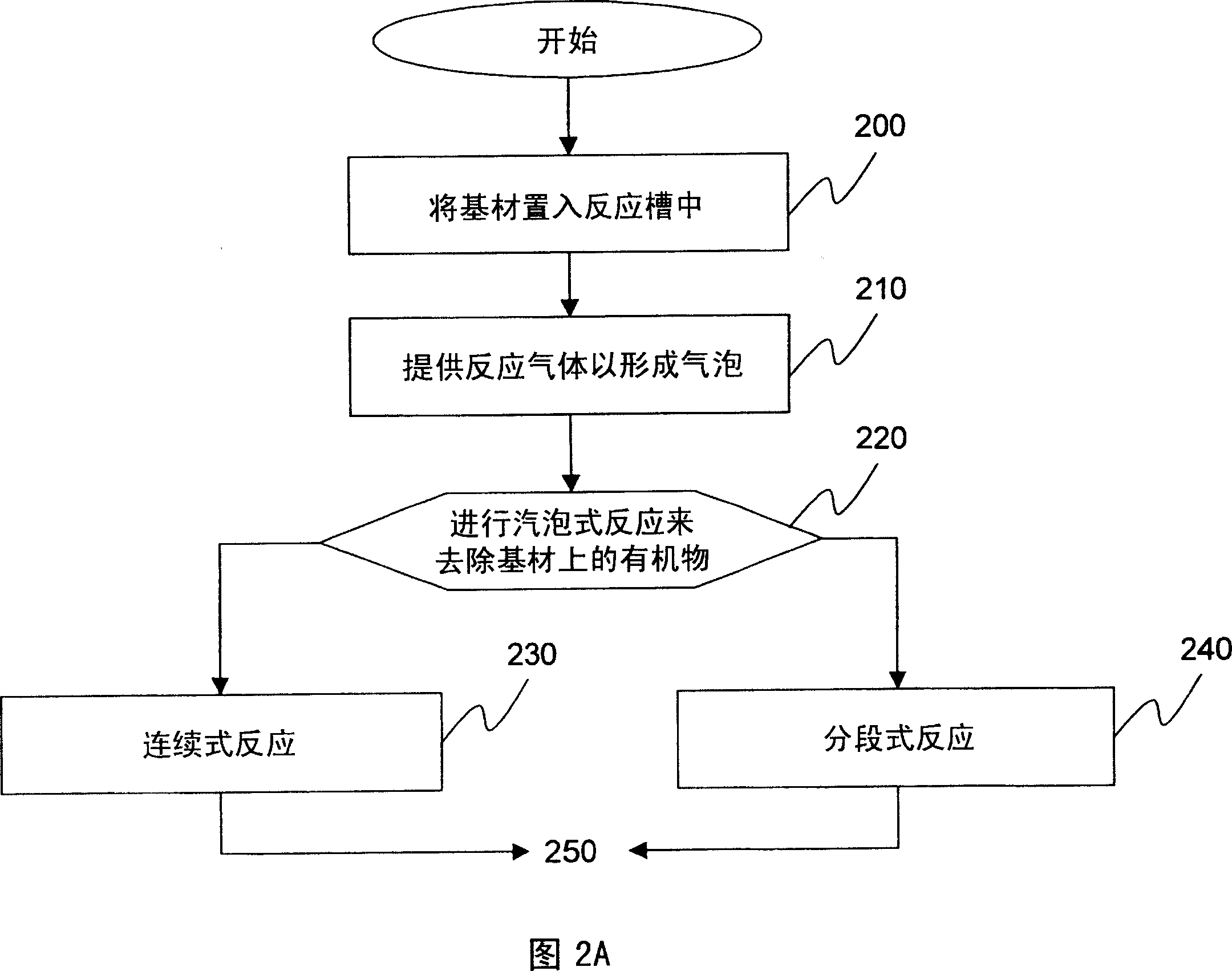

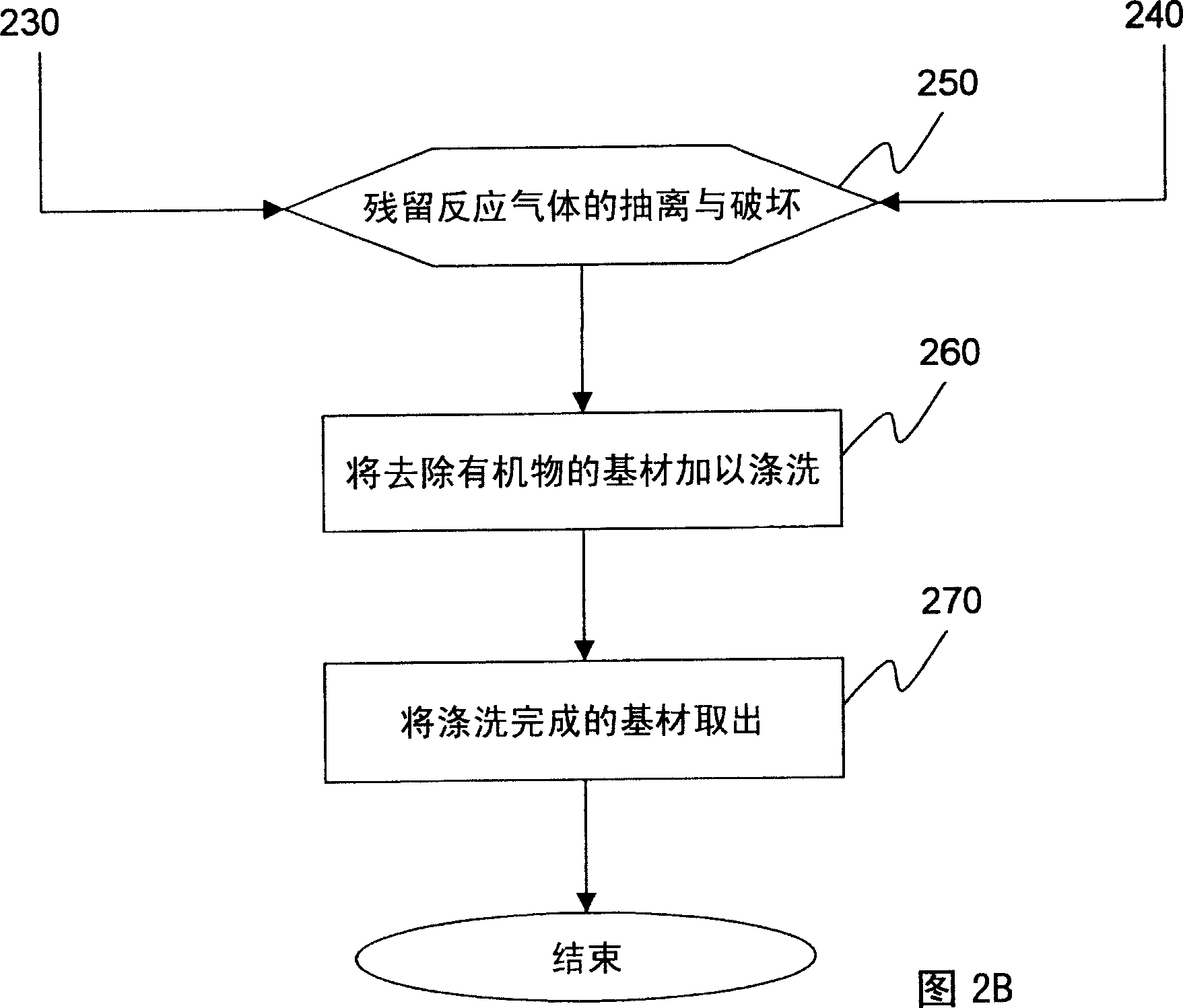

[0056] In order to have a further understanding of the purpose of the present invention, structural features and functions thereof, the accompanying drawings are described in detail as follows:

[0057] The present invention is a bubble reaction cleaning device, which uses bubble reaction to remove organic matter on the surface of a substrate. First, please refer to FIG. 1 , which is a schematic structural diagram of the bubble reaction cleaning device of the present invention.

[0058] The bubble type reaction cleaning device of the present invention comprises: reaction tank 10, motion unit 20, temperature control system 30, reaction liquid supply source 40, reaction gas supply source 50, pressure control system 60, bubble generation mechanism 70 and washing liquid supply The source 80 and the reaction tank 10 are used to accommodate the substrate 90, and provide a space for cleaning the substrate 90, while the substrate 90 is placed on the motion unit 20, and causes the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com