Organic LED based on anode modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

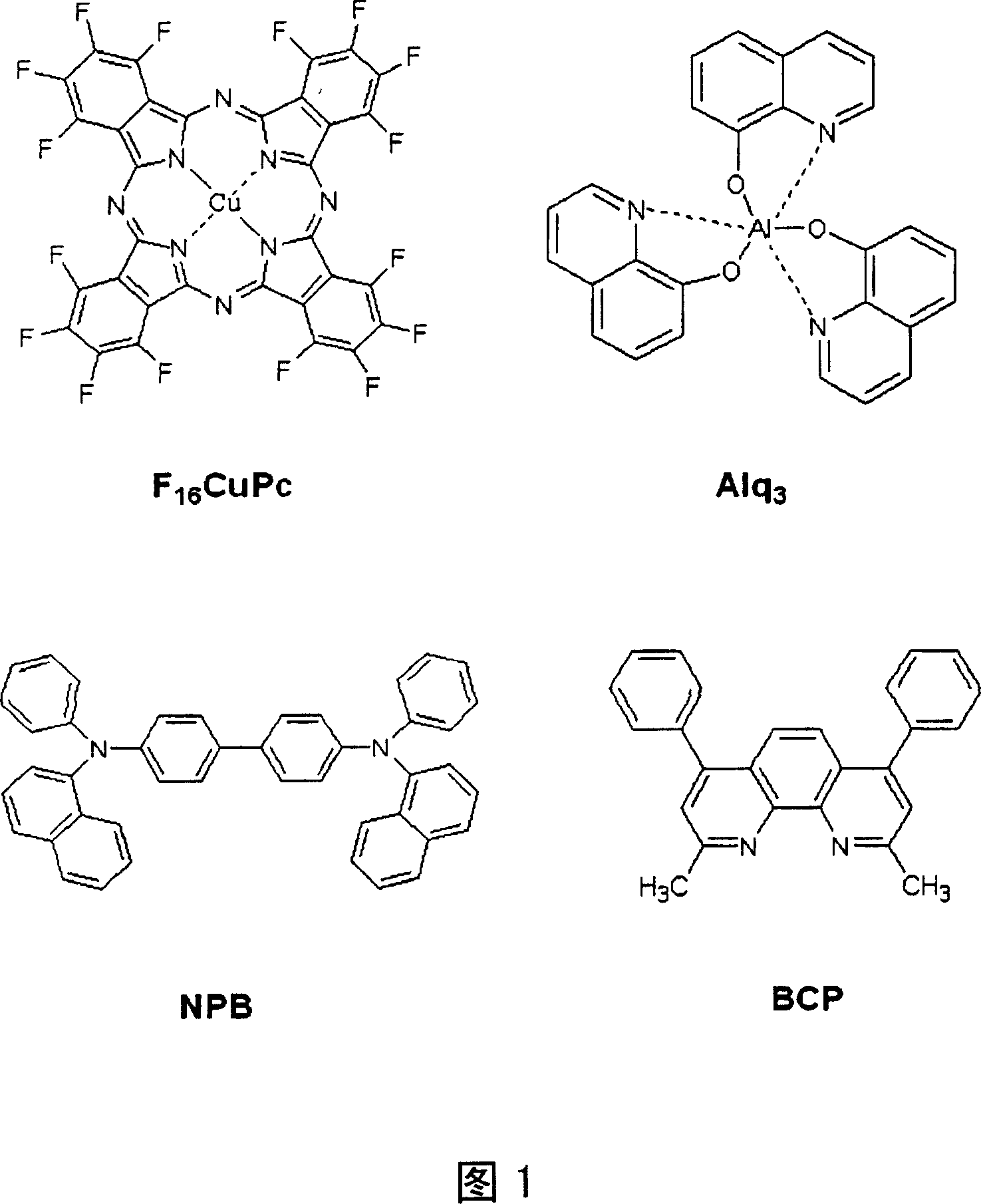

[0040] What shown in Fig. 1 is to be used to prepare the molecular formula of organic material of the present invention, be respectively strong electron-withdrawing molecule hexadecafluorophthalocyanine copper (F 16 CuPc), electron transport materials and luminescent materials 3-(8-hydroxyquinoline) aluminum (Alq 3 ), the hole-transporting material 4,4-2[N-(1-naphthalene)-N-aniline]bisphenyl (NPB) and the hole-blocking material 2,9-dimethyl-4,7-diphenyl- 1,10-Phenanthroline (BCP).

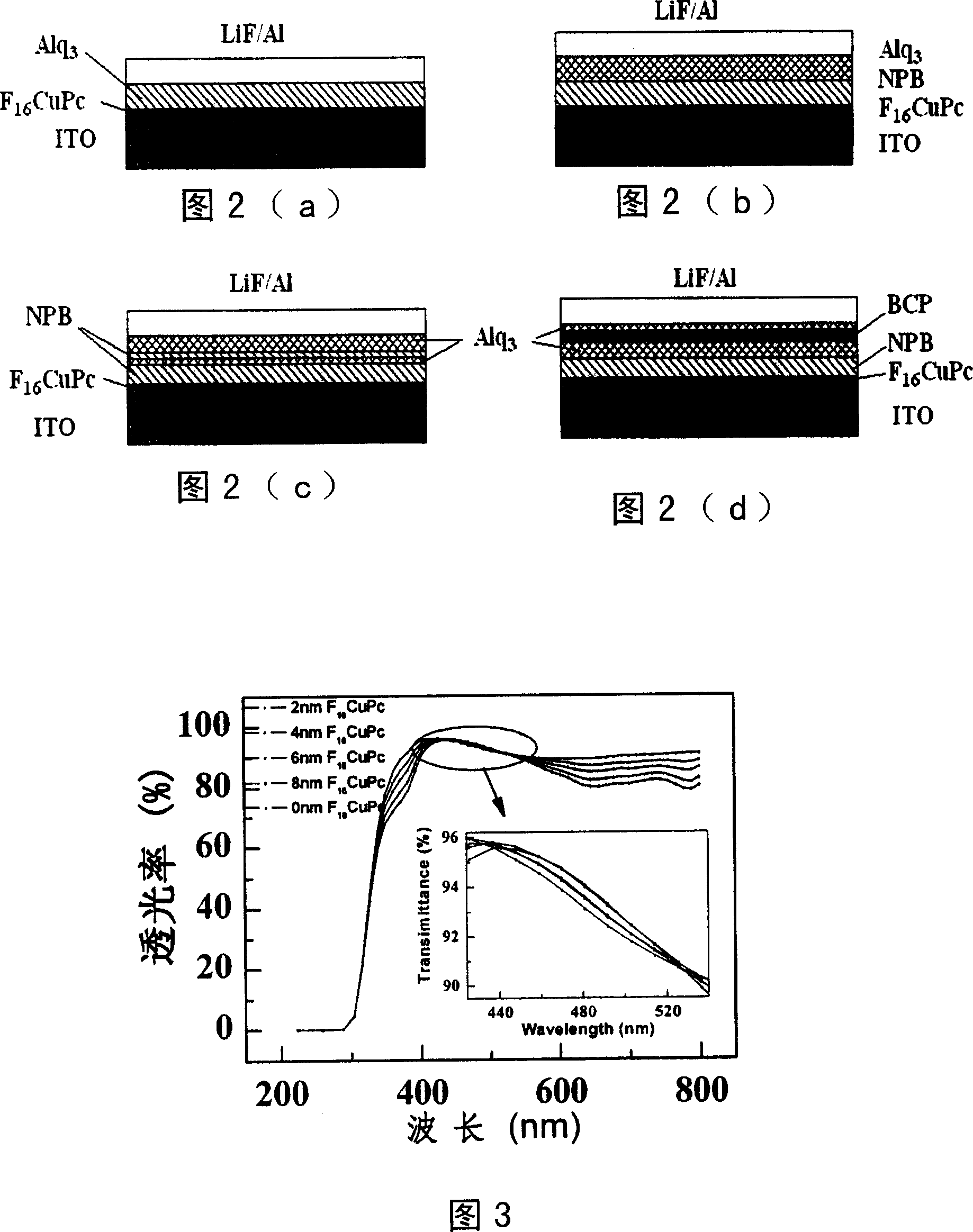

[0041] An organic light emitting diode structure of the present invention sequentially includes a substrate, a transparent bottom electrode of indium tin oxide (ITO), an organic layer and a cathode. The substrate can be made of the following materials: glass, ceramics, polymers, etc. The organic layer can be single layer, double layer and multilayer. The cathode is used for injection of electrons, and the electrode is made of a material with a low work function. It can be one metal or multiple ...

Embodiment 2

[0055] Prepared by the method of Example 1, the only difference is that the organic layer is a double-layer structure (NPB / Alq 3 ) (as shown in Figure 2b), both layers are 50nm. A low turn-on voltage (brightness up to 1cd / m 2 Voltage) of organic light-emitting diodes, the minimum turn-on voltage is 2.53V, reaching 100cd / m 2 The minimum voltage is 3.9V.

[0056] Fig. 5 is a graph showing current density-voltage, luminance-voltage and efficiency-current density curves of an organic light-emitting diode with a double organic layer structure according to the present invention.

[0057] Figure 6 is the surface atomic force microscope image of ITO and ITO / 4,4-2[N-(1-naphthalene)-N-aniline]biphenyl (NPB) before and after anode modification, wherein Figure 6a is ITO and Figure 6b is ITO / copper hexadecafluorophthalocyanine (F 16 CuPc), Figure 6c is ITO / NPB, Figure 6d is ITO / F 16 CuPc / NPB.

Embodiment 3

[0059] Prepared according to the method of Example 1, the only difference is that the organic layer is a multilayer structure, and the device structure is ITO / F 16 CuPc(4nm) / NPB(45nm) / Alq 3 (5nm) / NPB(5nm) / Alq 3 (45nm) / LiF / Al (as shown in Figure 2c). Obtained organic light-emitting diodes with high efficiency and low turn-on voltage, the highest efficiency is 7.63cd / A, and the turn-on voltage is 2.9V, reaching 100cd / m 2 The minimum voltage is 4.3V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com