Semiconductor metal capacitor

A metal capacitor and semiconductor technology, applied in the field of capacitors, can solve problems such as unsatisfactory effect and increase the complexity of semiconductor devices, and achieve the effect of increasing the unit capacitance density and increasing the facing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

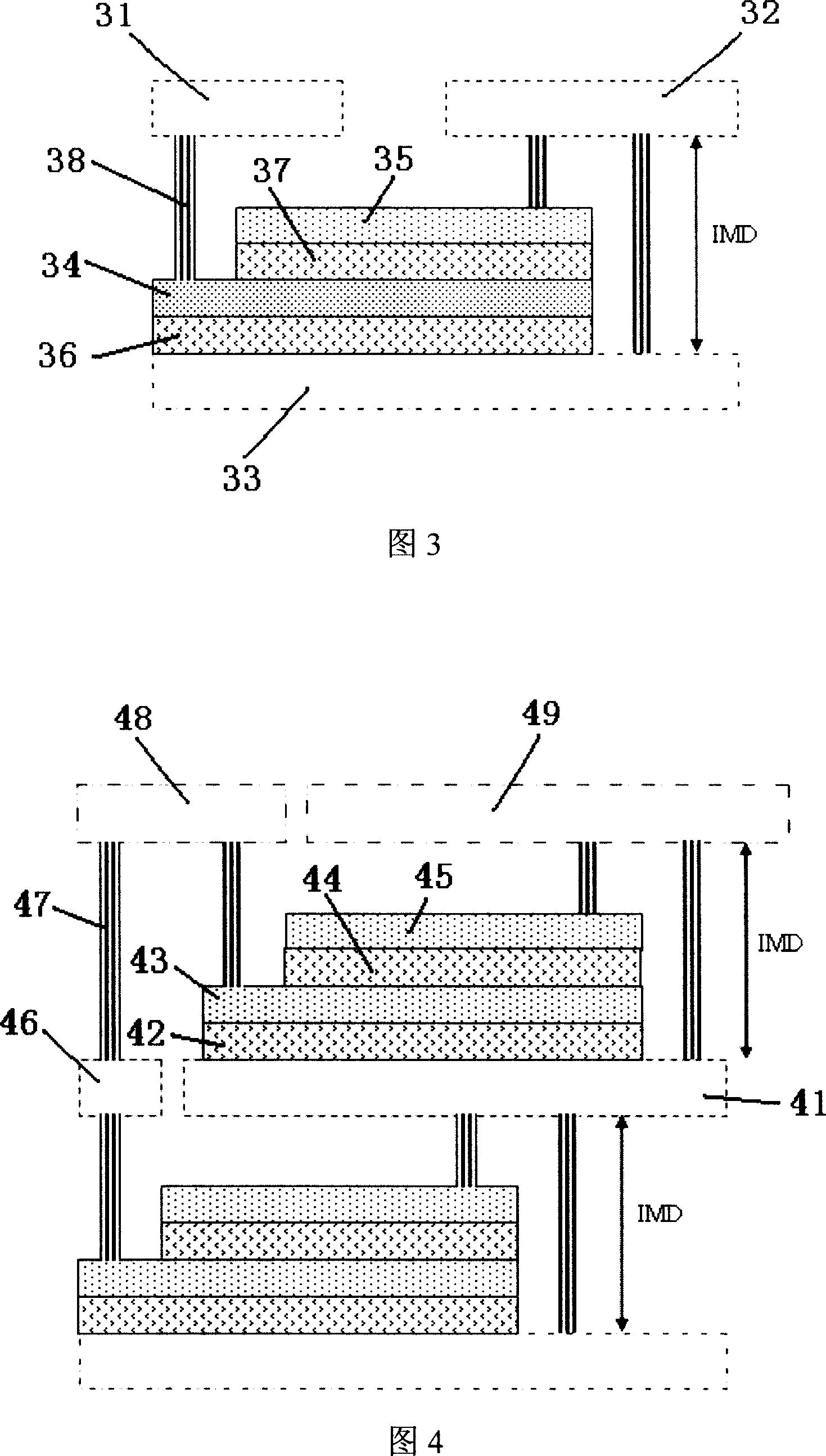

[0013] Fig. 3 shows that the present invention is used for the structural representation of single-layer filling dielectric layer IMD, comprises two output electrodes 31 and 32, upper metal plate 33, middle metal plate 34, lower metal plate 35, two layers of dielectric layers and filling material, the filling material constitutes the filling medium layer IMD, and the capacitor is a stacked structure, which consists of a lower metal plate 35, a dielectric layer 36, an intermediate metal plate 34, another dielectric layer 37 and an upper metal plate from bottom to top. 33, the middle metal plate 34 is connected to an output electrode 31 by a metal through hole 38 that passes through the filling material and is filled with a conductive material inside, and the upper layer metal plate 33 and the lower layer metal plate 35 are respectively connected by passing through the filling material A metal via 38 filled with a conductive material is connected to another output electrode 32 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com