Self-emission panel and method of manufacturing the same

A manufacturing method and self-illumination technology, applied in electroluminescent light sources, semiconductor/solid-state device manufacturing, light sources, etc., can solve the problems of reduced productivity, hindrance to the miniaturization/lightweight of electronic equipment, and rising costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

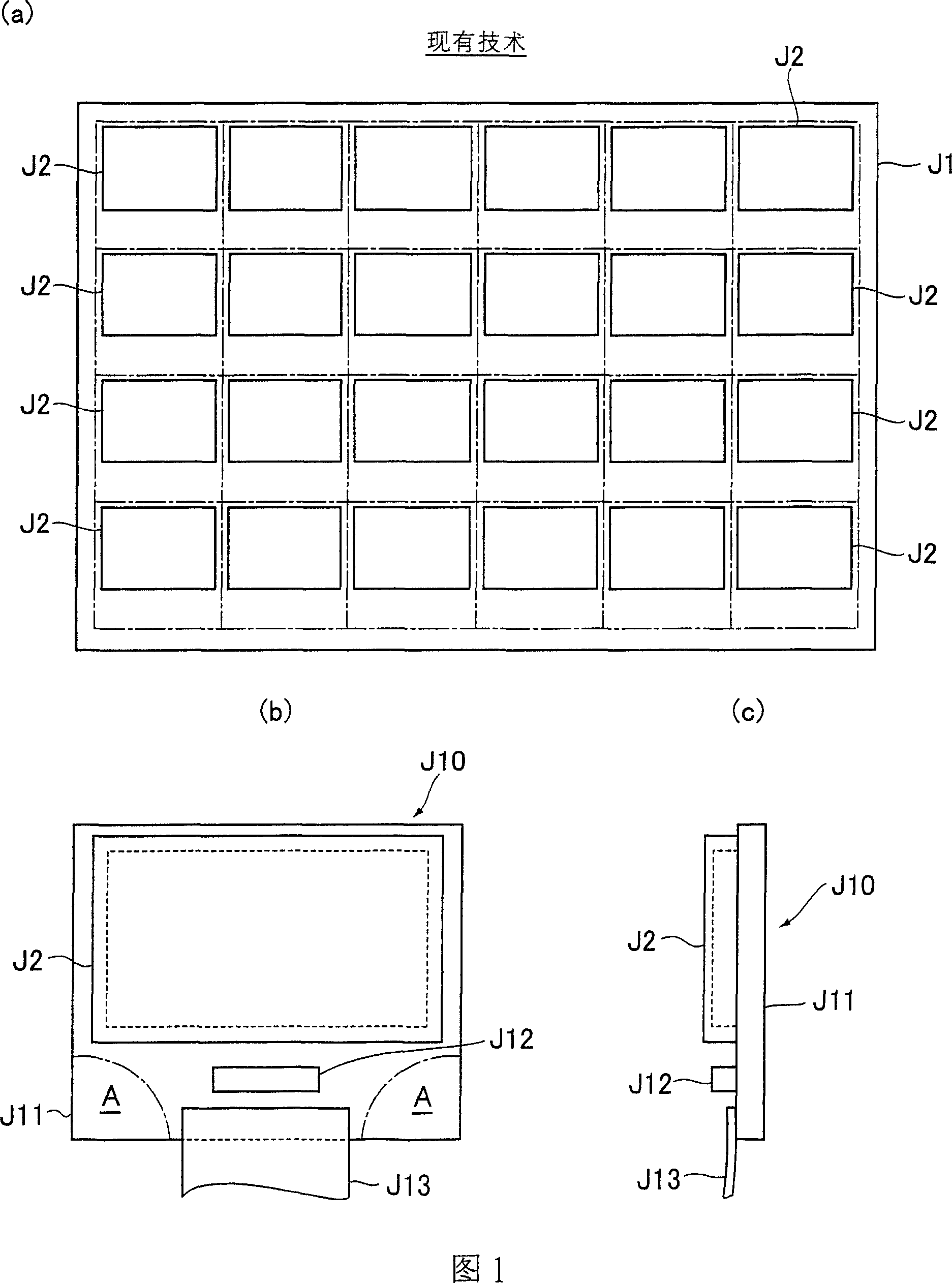

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

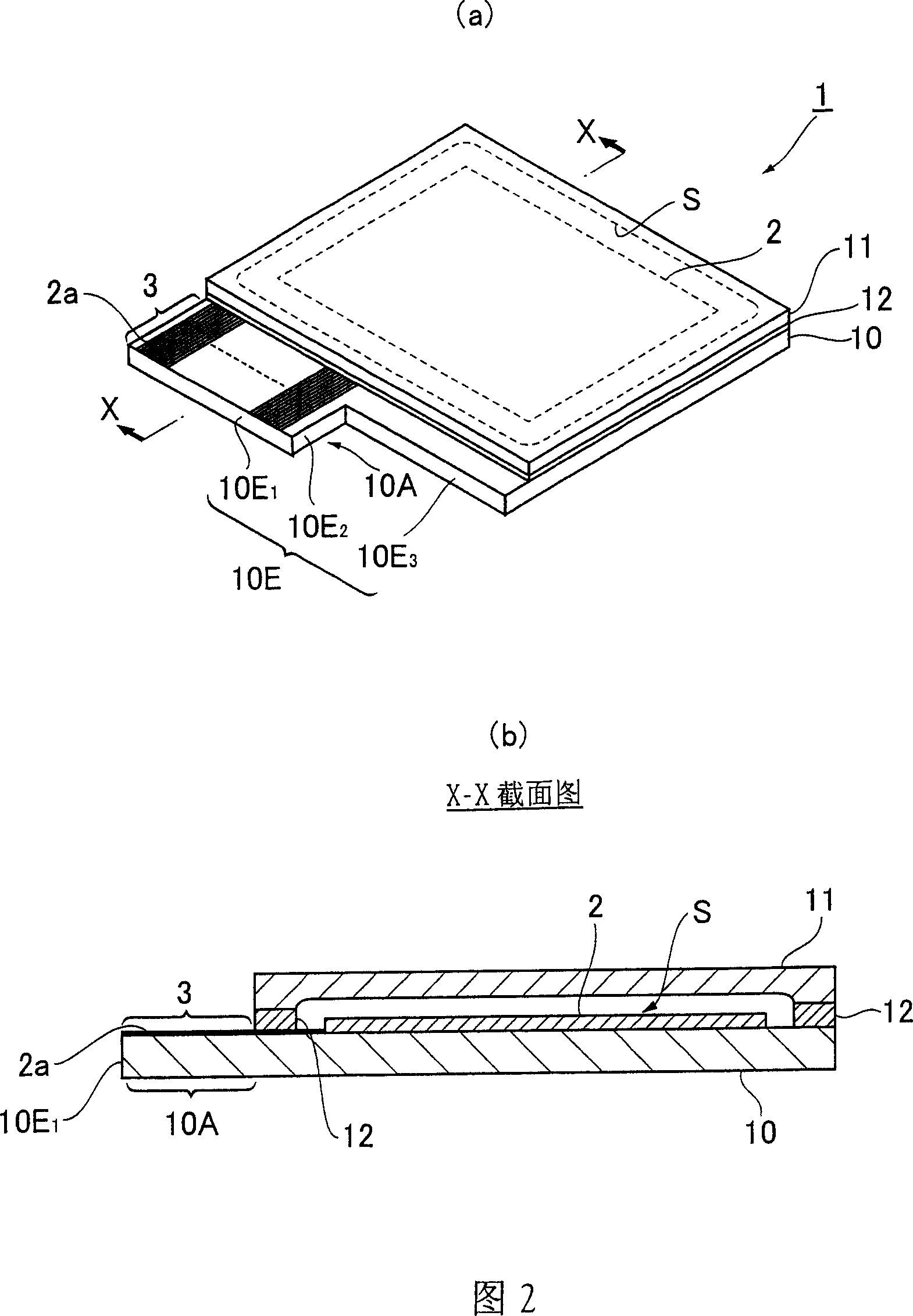

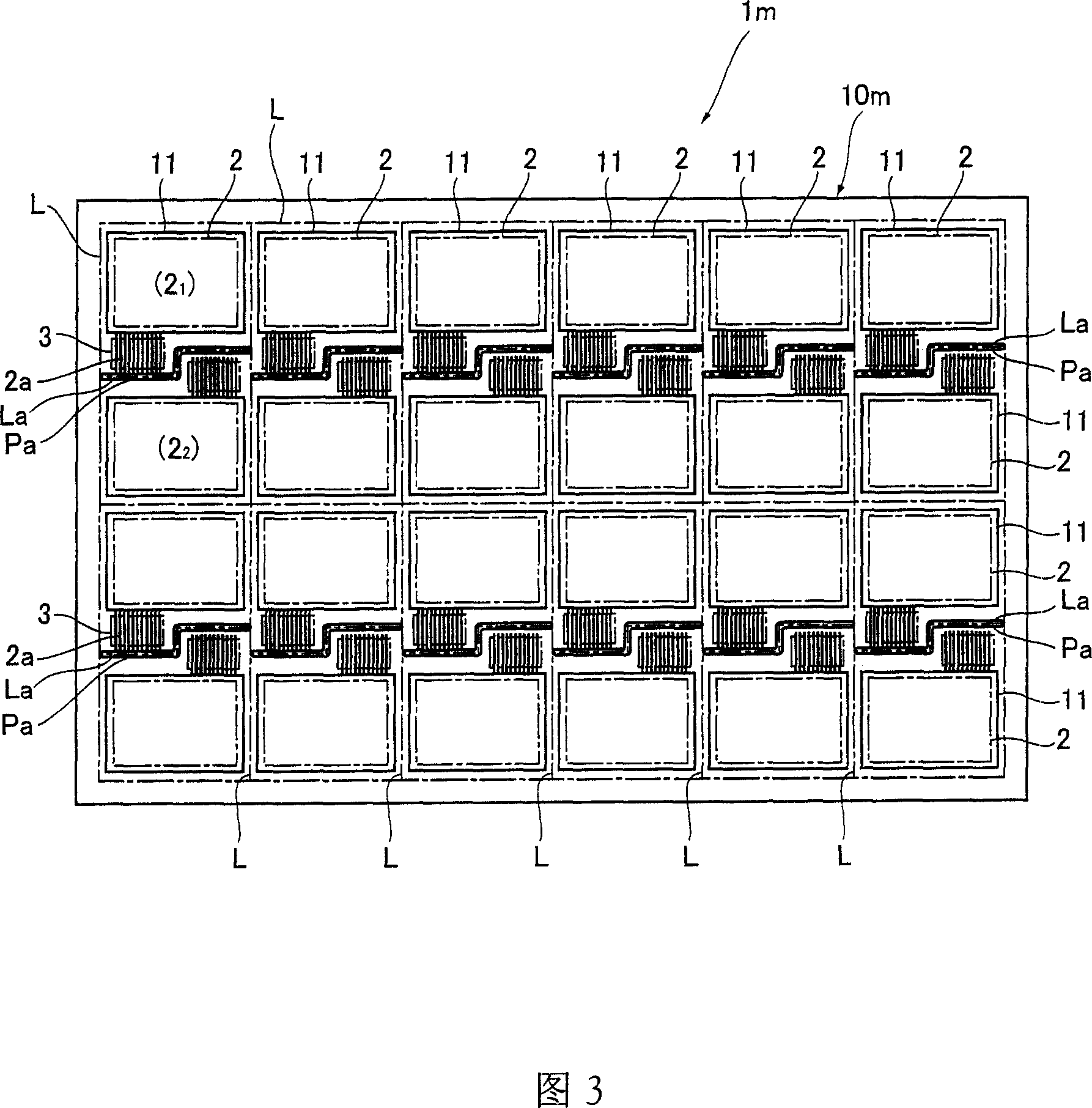

[0024] Hereinafter, embodiments of the present invention will be described with reference to the drawings. FIG. 2 is an explanatory view showing the overall structure of a self-luminous panel according to an embodiment of the present invention, in which FIG. 2( a ) shows an overall perspective view, and FIG. 2( b ) shows an X-X sectional view.

[0025] In the self-luminous panel 1, the self-luminous part 2 is formed on the support substrate 10, and the self-luminous part 2 is arranged in the sealing area S formed by bonding the support substrate 10 and the sealing member 11 through the adhesive layer 12, so that the self-luminous part 2 is formed. The connection part 3 of the lead wiring 2a drawn from the light-emitting part 2 to the outside of the sealing area S is formed on the support substrate 10 in an area other than the self-light-emitting part 2, and the connection part 3 connects the driver IC (not shown) and the flexible substrate. . In addition, an example in which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com