Deep hole drilling bit and blade

A technology of deep hole drill bit and taper, which is applied in the direction of boring/drilling, drilling/drilling equipment, drilling repair, etc. It can solve problems such as difficulties in making eccentric taper, and achieve the effect of improving processing accuracy and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

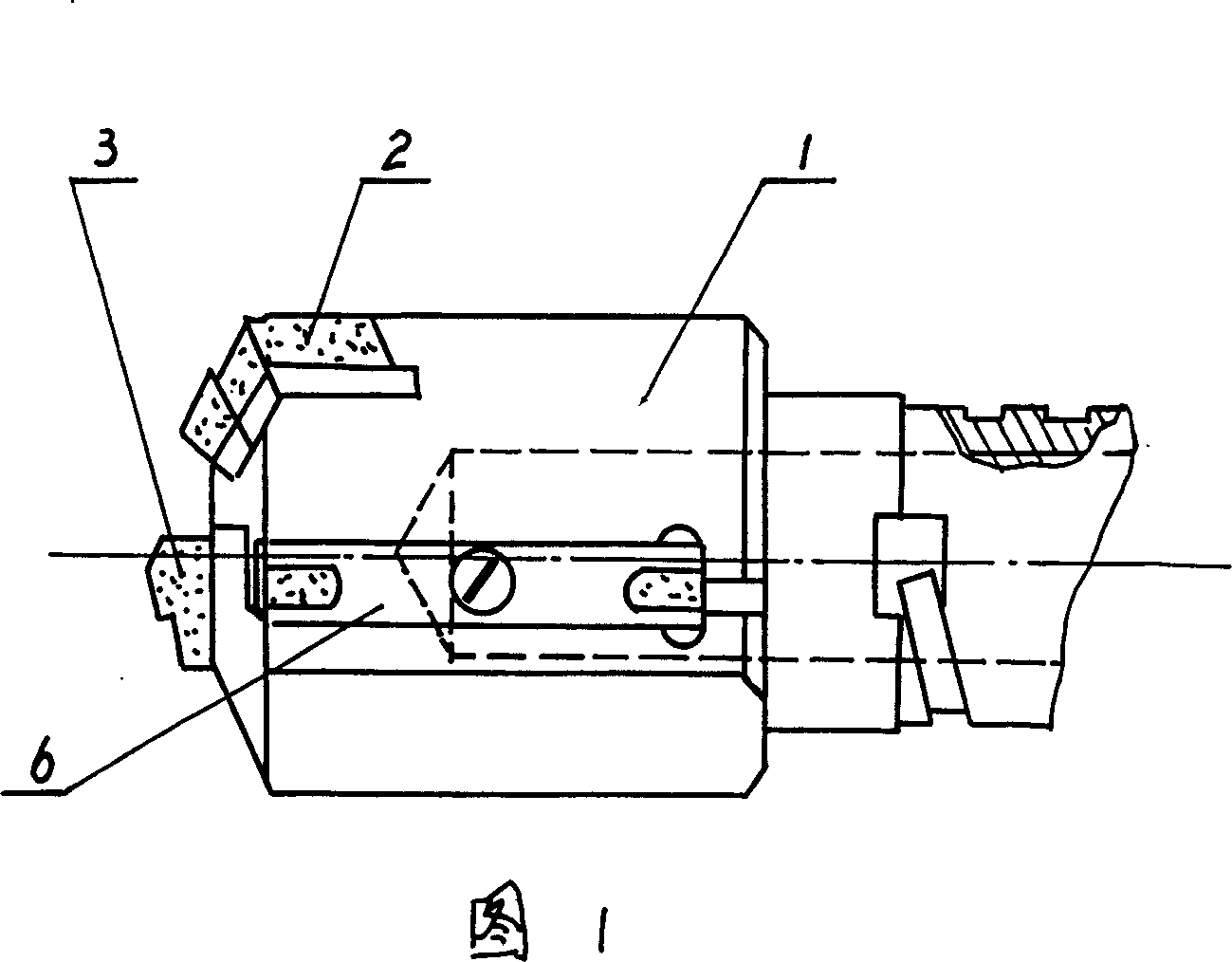

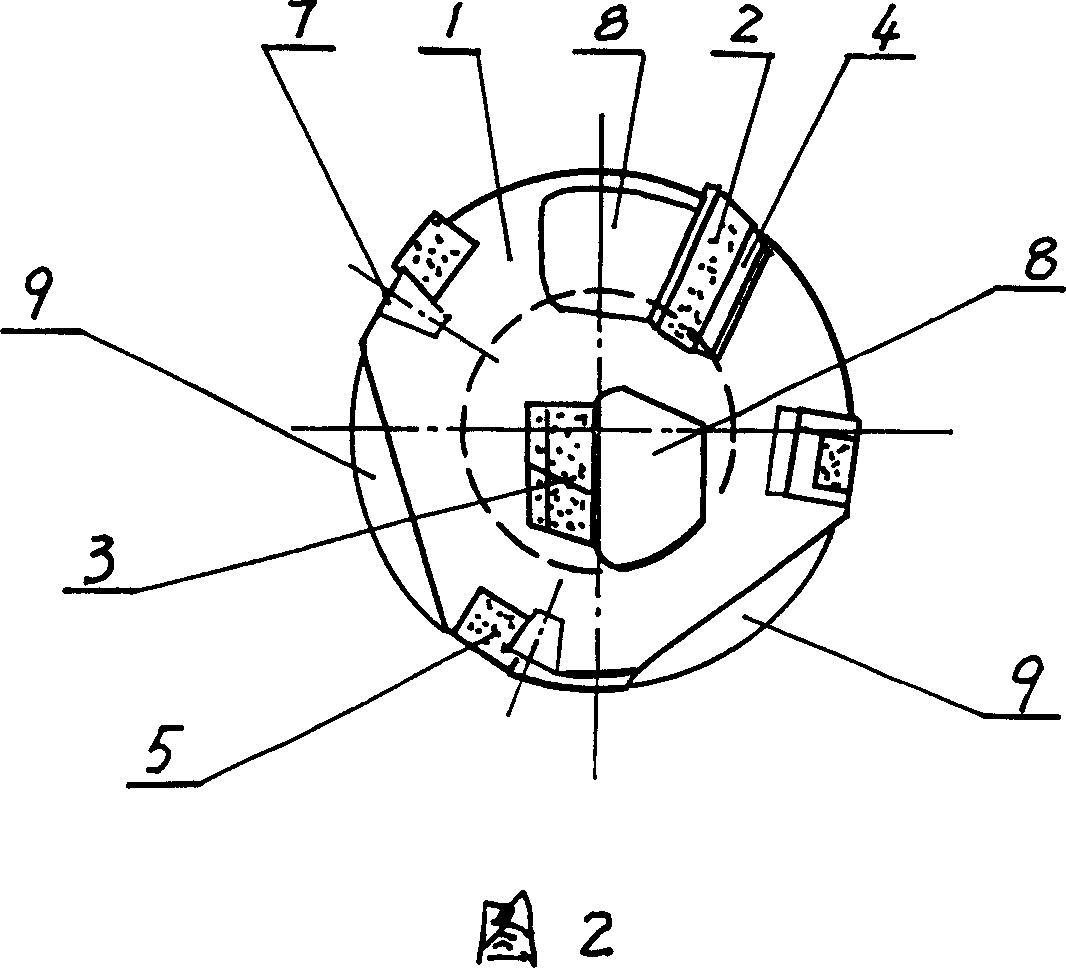

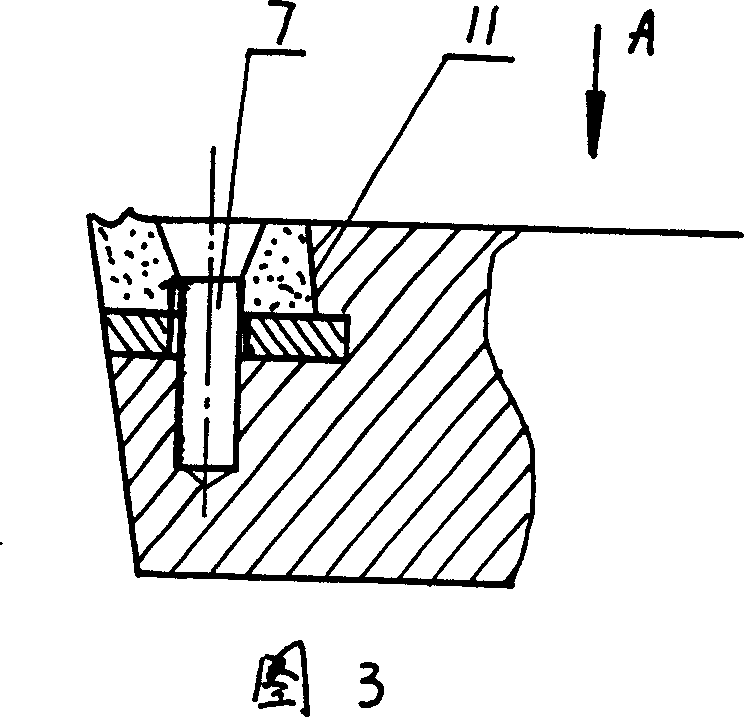

[0016] Accompanying drawing is the embodiment of the present invention, and it comprises cutter body 1, outer cutter 2, inner cutter 3, guide member 5, live key 6, taper screw 7, chip removal hole 8, oil inlet gap 9 etc. Each of the two chip removal holes 8 has a dovetail blade machine card, and the dovetail blade machine card includes a radial dovetail groove 11, an axial reference plane 13, and a machine card bottom surface. The reference plane 13 is perpendicular to the bottom surface of the blade machine card and the radial dovetail groove 11 . There are two threaded holes perpendicular to it in the datum plane 13, and two adjusting screws 10 are installed inside, which are used for adjusting the size after grinding the blade. The middle part of the bottom surface of the blade machine card is provided with an eccentric threaded hole based on the blade hole, which is used to fix the blade. A knife shim 4 is placed under the blade to increase the strength of the blade and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com