Continuous carbonizing treatment method by internal heating self-combusting mode

A treatment method and carbonization technology, which can be used in combustion methods, rotary carbonization furnaces, incinerators, etc., and can solve problems such as rising fuel costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

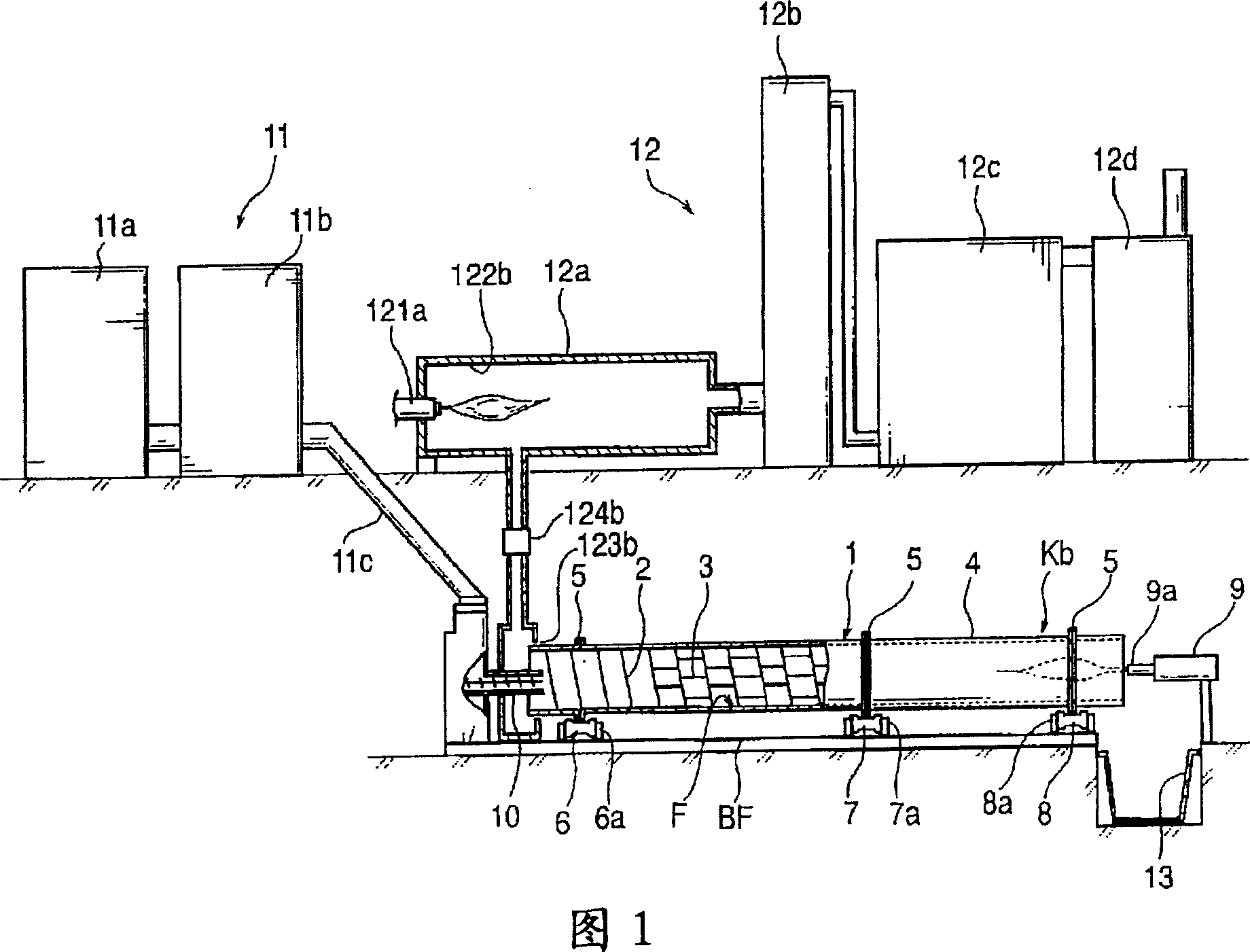

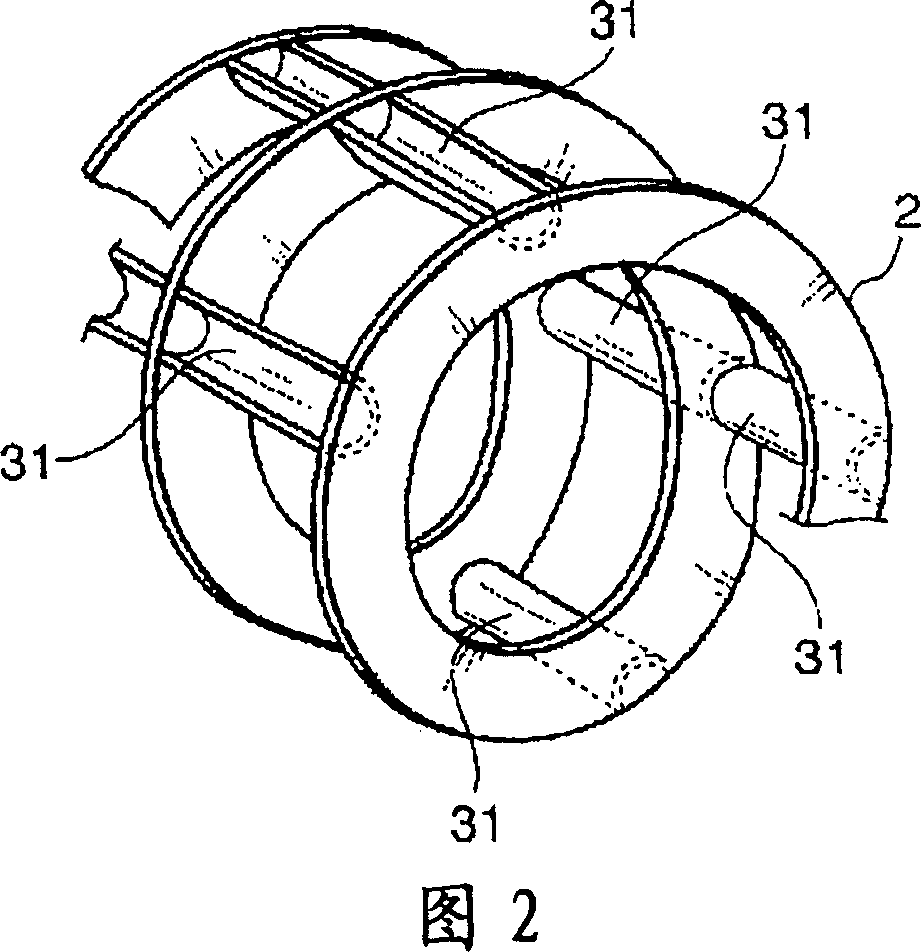

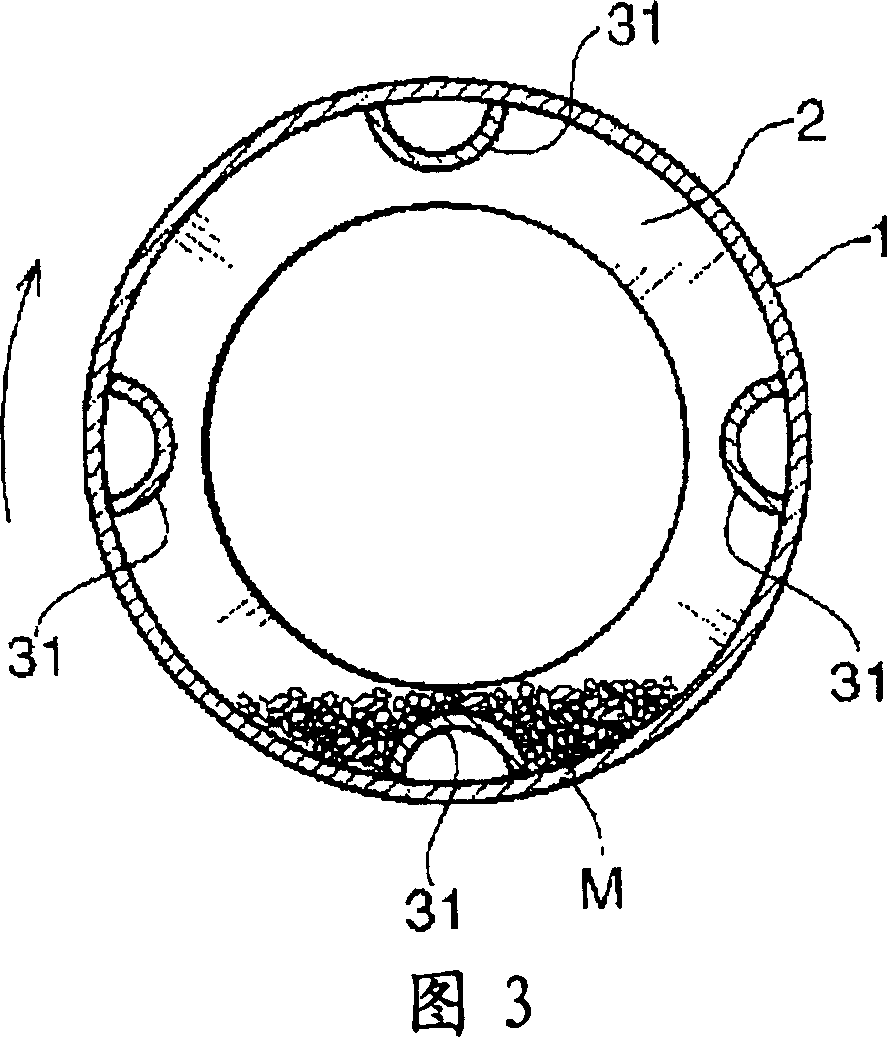

[0016] In FIG. 1 , 1 is a steel pipe cylinder having a length of about 10 to 15 m and an inner diameter of about 30 to 80 cm. Here, a plurality of required cylinders per unit length are connected by an outer flange-shaped joint, thereby forming one cylinder 1 .

[0017] Reference numeral 2 denotes a conveying wall provided on the inner surface of the above-mentioned cylinder 1 so as to form a spiral over the entire length of the cylinder 1 . A stirring wall 3 having a substantially semicircular, substantially triangular, or substantially trapezoidal cross-section is provided on the portion from upstream to the middle of the spiral conveying wall 2 in a direction transverse to the conveying wall 2 of this portion.

[0018] Reference numeral 4 denotes a heat insulating layer provided outside the entire length of the above-mentioned cylindrical body 1 . The rotary kiln main body Kb is formed from the above-mentioned structure from the cylinder body 1 to the heat insulating layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com