Carbon film coating method and device for quartz crucible for use in crystal growth

A quartz crucible and crystal growth technology, applied in crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of complex gas flow control, long carbon plating time, etc., to avoid parasitic nucleation and good crystallization integrity , to avoid the effect of polycrystalline growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

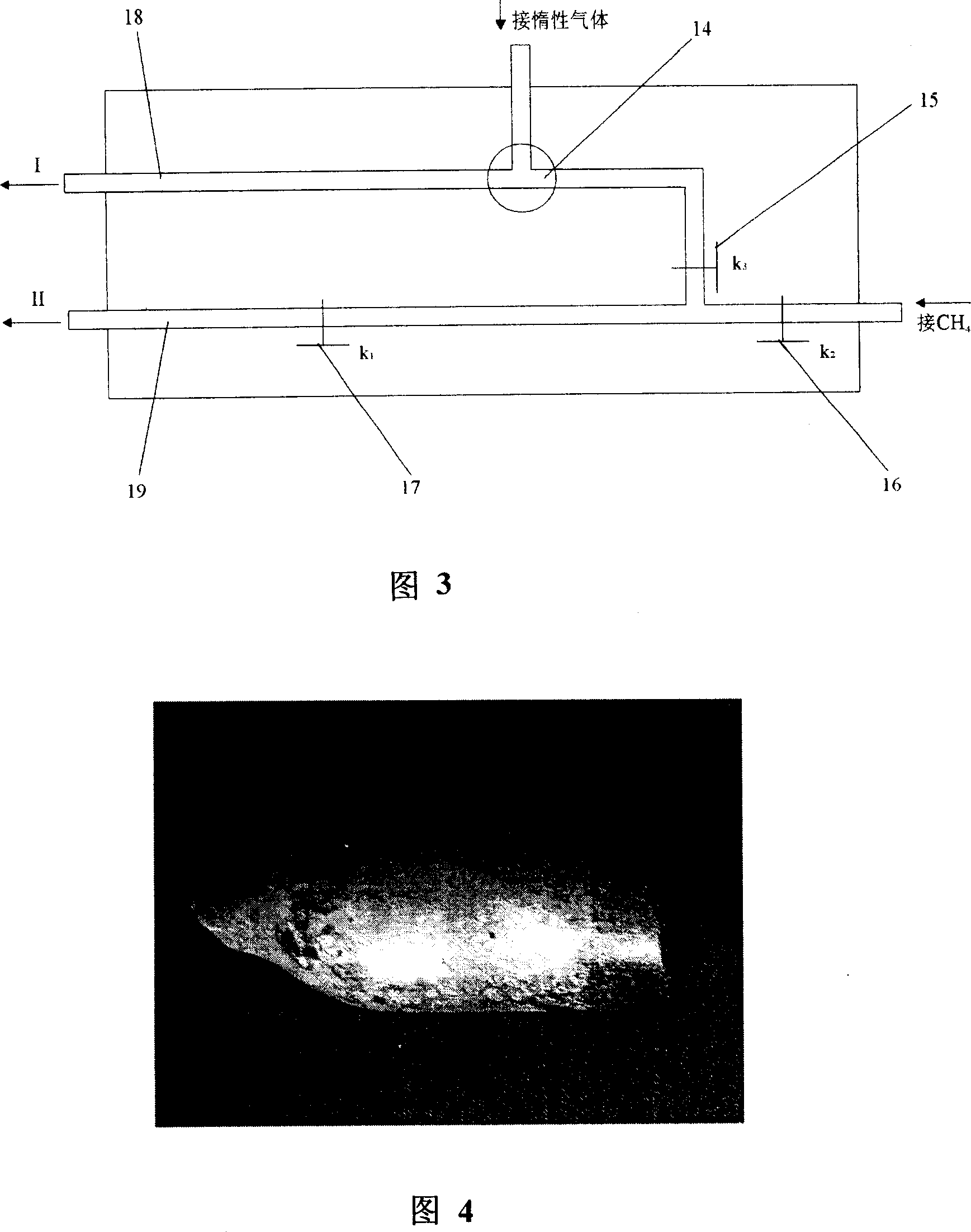

[0041] In this embodiment, the inner wall of the quartz crucible for crystal growth shown in FIG. 1 is coated with a carbon film, and the structure of the coating device and the installation method of the quartz crucible are shown in FIG. 2 . The coating device includes a heating furnace, a precipitation chamber 8 for placing a quartz crucible to be coated, and a gas supply controller 11; the heating furnace is a single temperature zone resistance furnace, including a furnace body 1, a heating element 4 installed on the furnace body, and temperature control and temperature measurement The heating element 4 is distributed along the axial direction of the furnace body, and the temperature control temperature detector is composed of a thermocouple 2 installed at the temperature measurement point in the furnace of the heating furnace and a FP93 temperature control indicator instrument 3 connected to the thermocouple (the temperature control accuracy is 1° C.), the lower part of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com