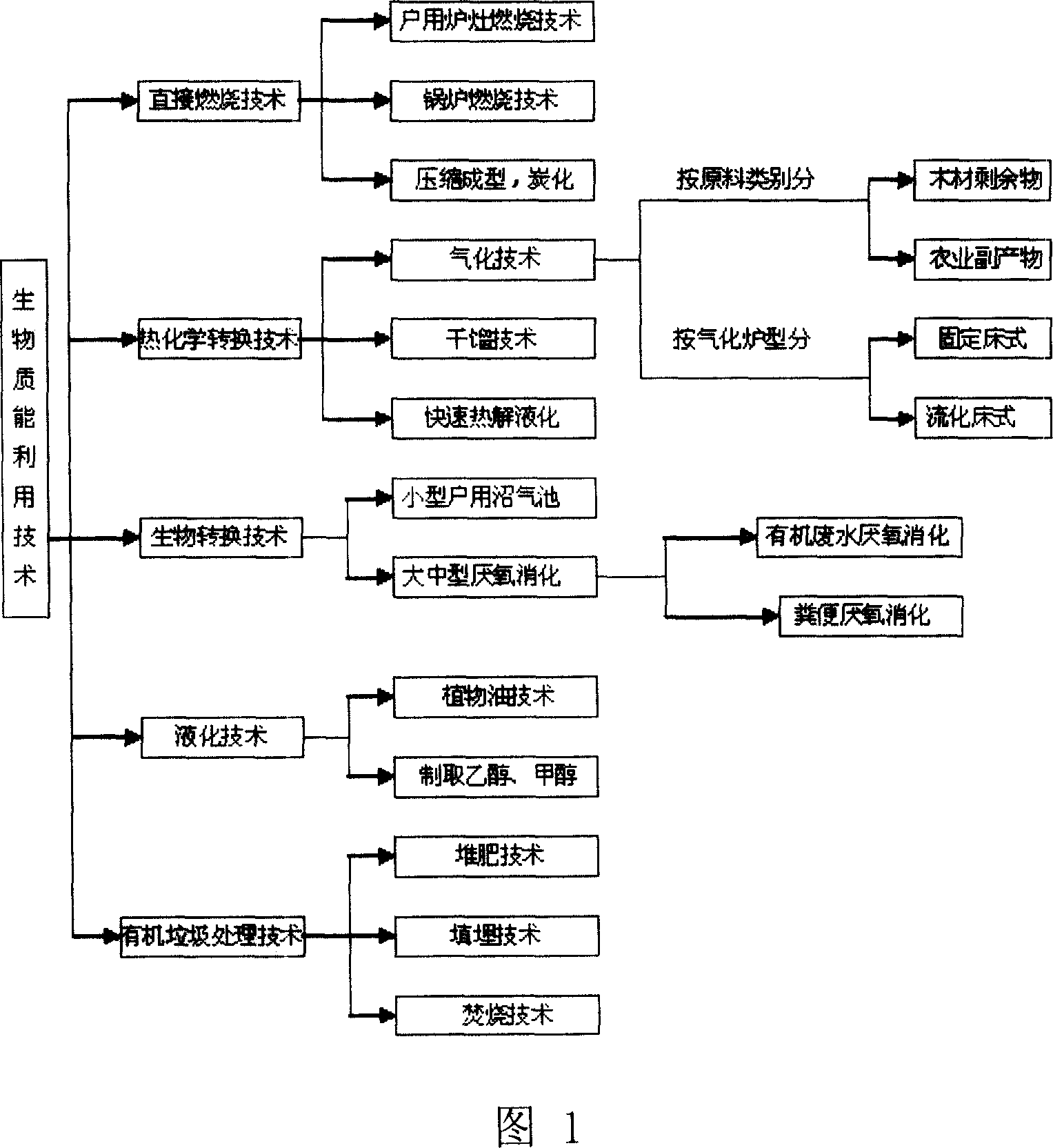

Process for preparing bio-oil by using rapid thermal cleavage technology

A technology of biomass oil and thermal cracking, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., to achieve the effects of increasing production, high yield and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

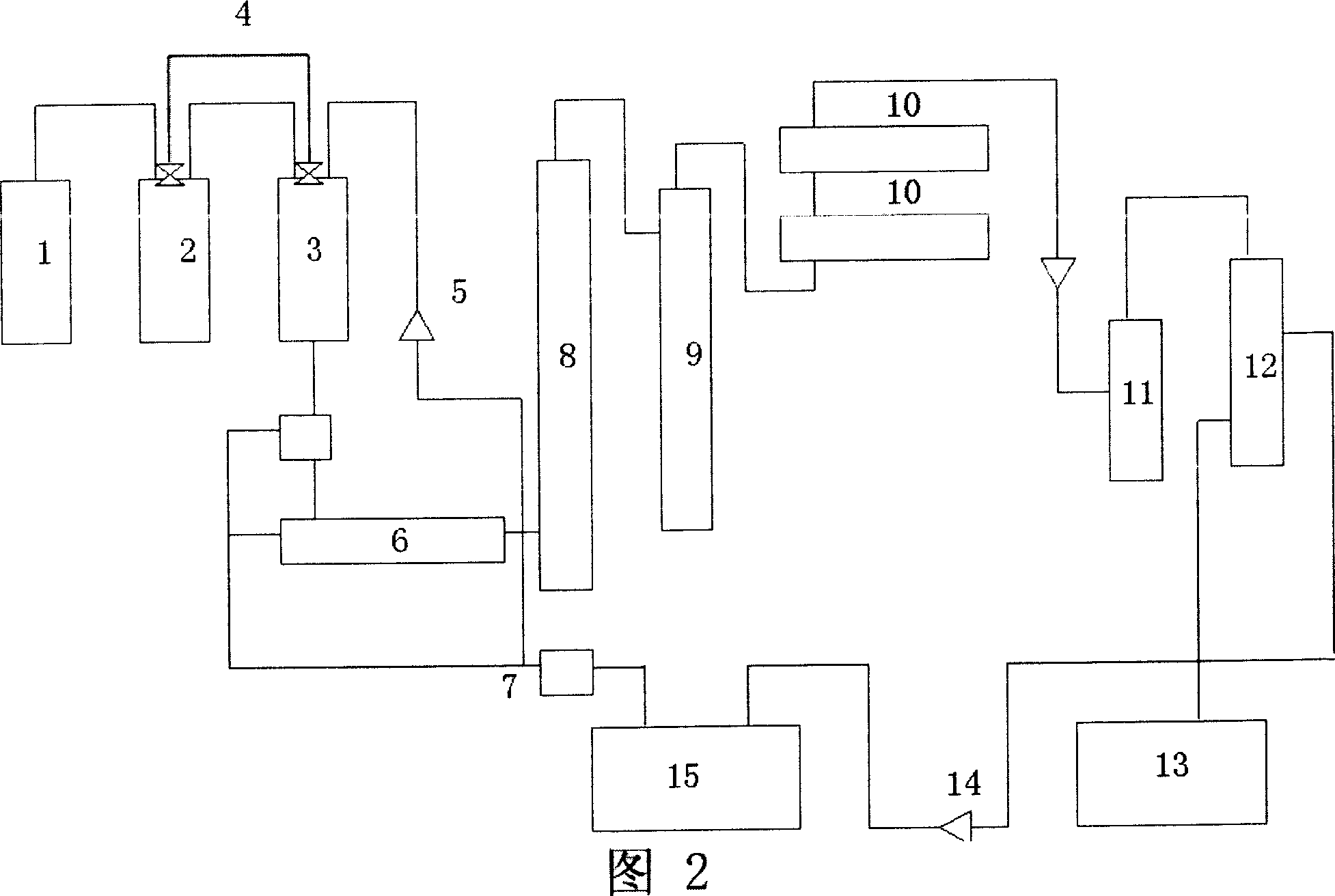

[0052] The implementation of this example is as follows. The test scale is 500kg / h (500kg of material throughput per hour, 1-2 tons of material oil per day).

[0053] (1) Drying: In order to avoid excessive moisture in the material being brought into the bio-oil, the material must be dried. This embodiment uses a 7.5KW Shandi brand dryer with a motor power of 700kg per hour. . The moisture content of the dried material is required to be no more than 8%.

[0054] (2) Crushing: In order to increase the yield of biomass oil, the material needs to be pulverized. This is necessary to increase the heating rate. Because the particle size of the material is small enough to ensure a high heating rate is one of the important conditions. In this embodiment, rice husk is used as material; its particle size is 1-1.5 mm.

[0055] (3) Feeding. Conveying materials is one of the important technical links in the pyrolysis process. Because biomass pyrolysis is the biomass (material) under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com