Adjustable screwdriver structure

A screwdriver structure and adjustable technology, which is applied to screwdrivers, wrenches, wrench, etc., can solve the problems of operating screwdrivers, such as safety impact and lack of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

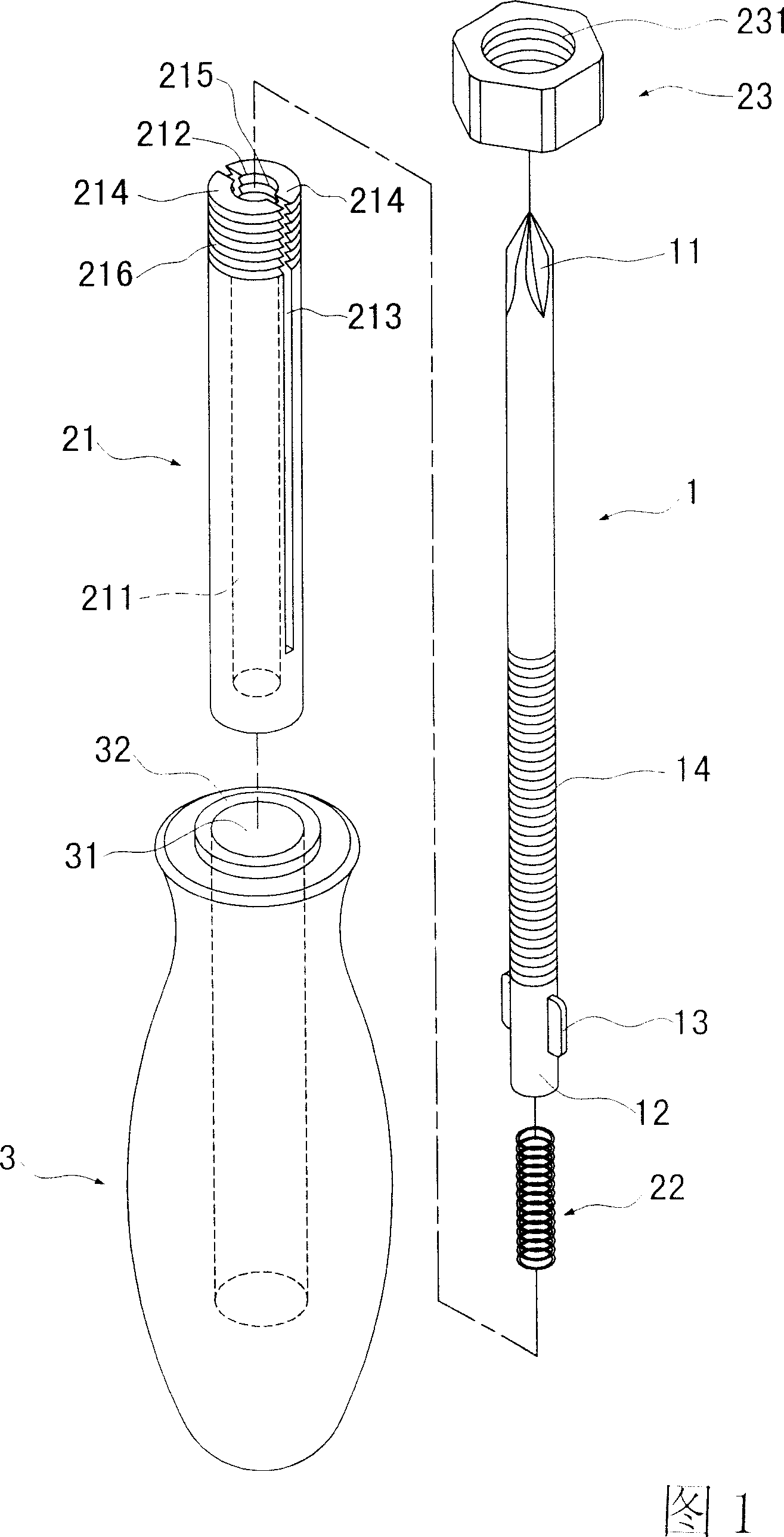

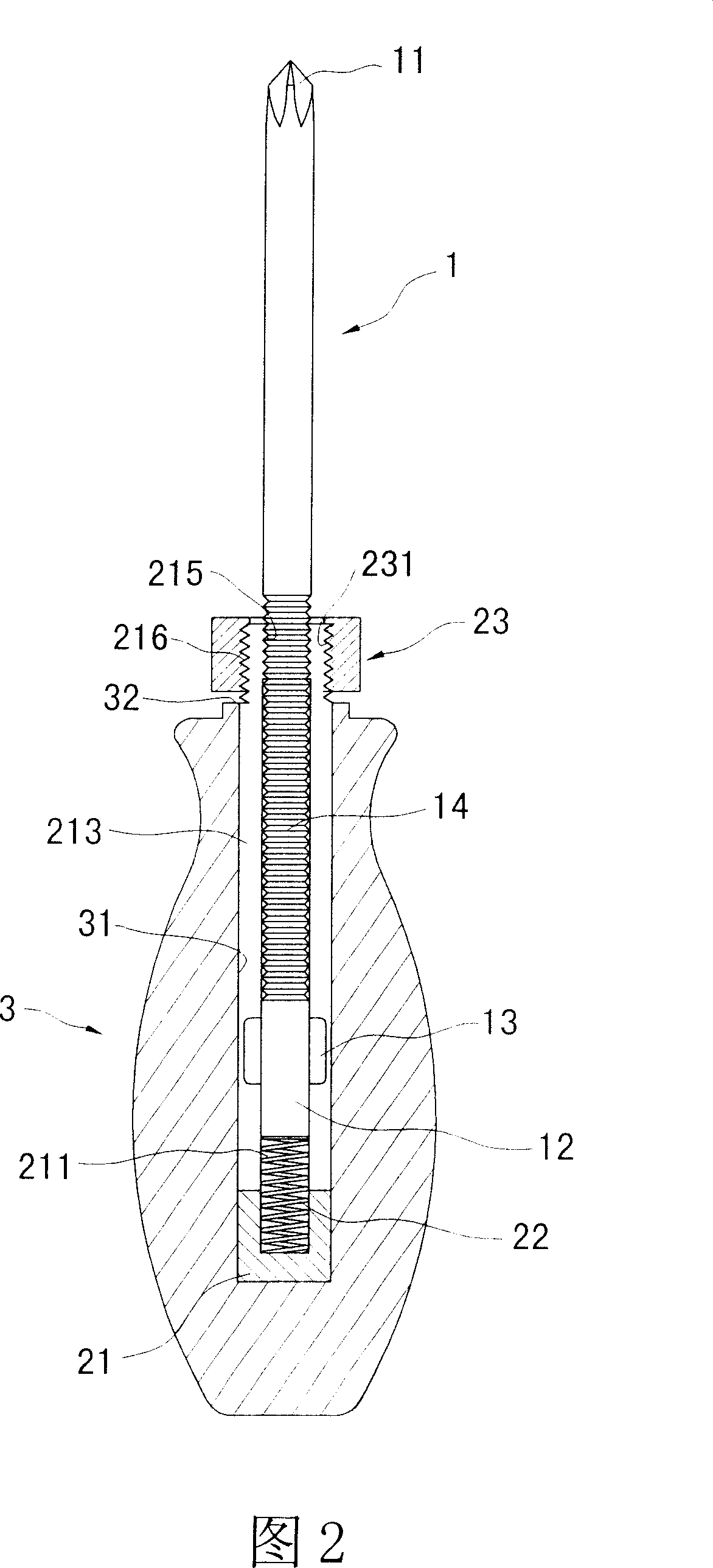

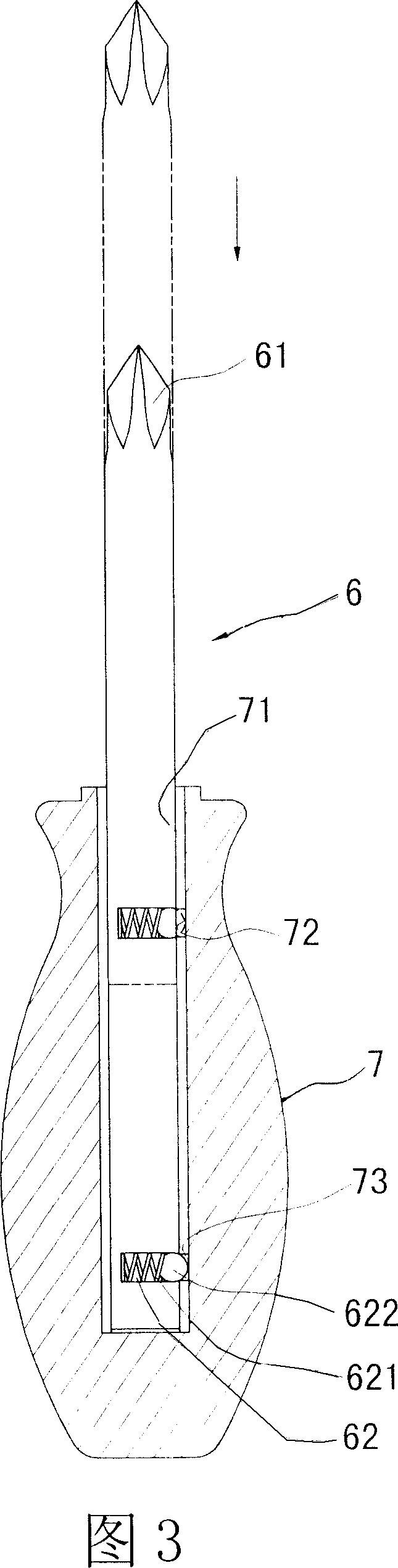

[0019] Referring to Fig. 1 to Fig. 2, the structure of the selected embodiment of the present invention is shown in the figure.

[0020] The adjustable screwdriver structure of the present embodiment includes:

[0021] A rod body 1, one end is a screw driver head 11, the screw driver head 11 is a cross screwdriver head in this embodiment, the other end of the rod body 1 has a socket section 12, and the rod body 1 is protrudingly arranged adjacent to the socket section 12 There are two symmetrical stoppers 13, and the rod body 1 has a stopper section 14 on the periphery. In this embodiment, the stopper section 14 is an external thread section.

[0022] A clamping part includes a rod 21, an elastic component 22 and an urging component 23, the urging component 23 is a nut in this embodiment, and the elastic component 22 is a compression spring in this embodiment . Wherein, the rod 21 has an accommodating space 211, and the rod 21 is provided with an opening 212 at one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com