Preparation method of polyethylene imine nanometer gelatin

A polyethyleneimine and nanogel technology is applied in the preparation of polyethyleneimine nanogels, the preparation of nanometer drug carriers and nanogene carriers, and can solve the problem of toxic residues affecting the biocompatibility of nanogels, Difficult to obtain pulsed high-energy electrons, low solid content of nanogels, etc., to achieve the effects of excellent storage stability and dispersion, pure nanogels, and green synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

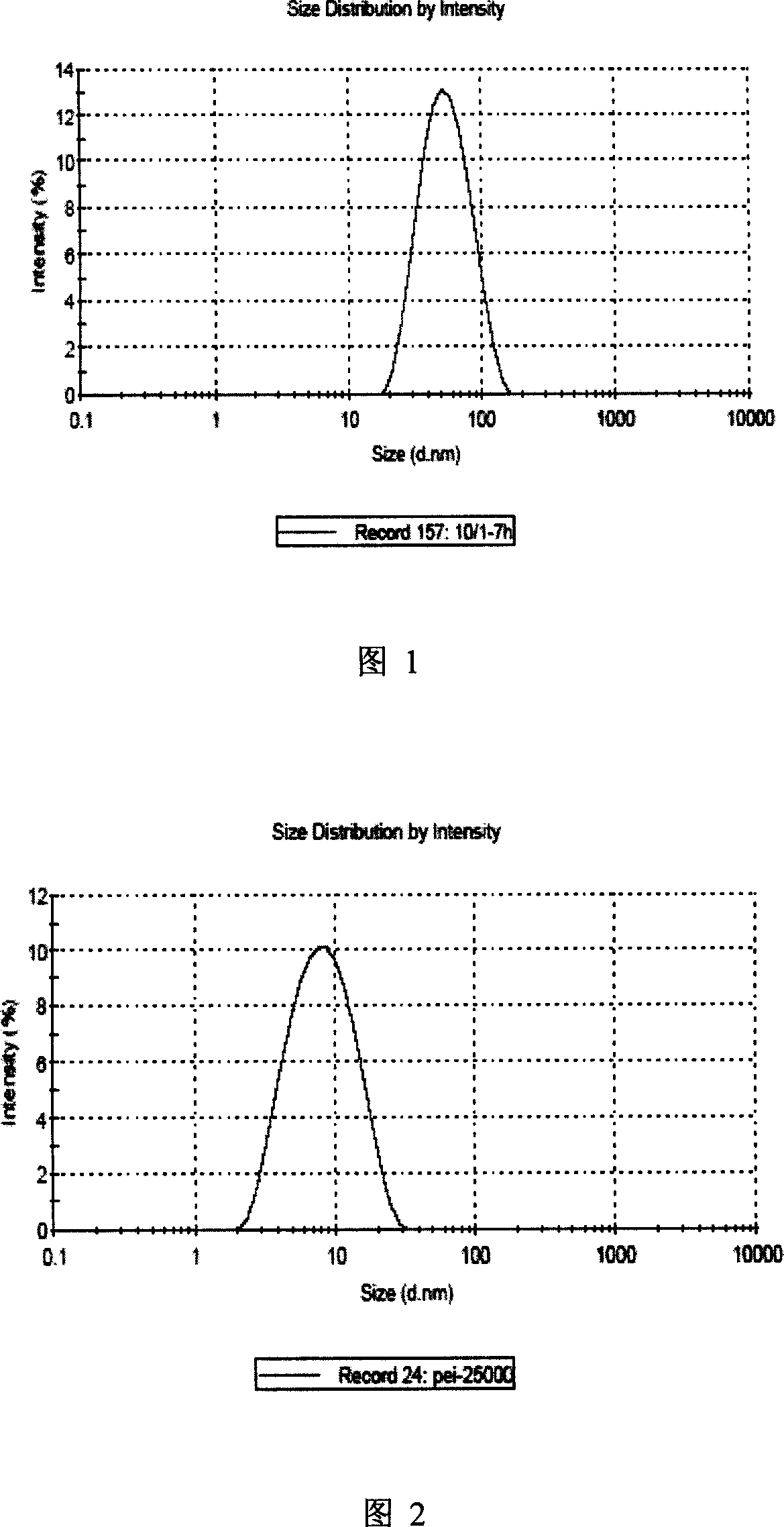

Embodiment 1

[0036] Take 5mL of polyethyleneimine aqueous solution with a concentration of 1g / L and a molecular weight of 600 in the reactor, deoxidize, and quickly add 3.7mL of FeCl with a concentration of 2.5g / L and a pH of 1 to 3 2 The solution was stirred and reacted at room temperature for 1 day, and unreacted reactants were removed. The particle diameter of the product measured by dynamic light scattering was 48nm, the polydispersity coefficient was 0.17, and the Zeta potential was 32mV.

Embodiment 2

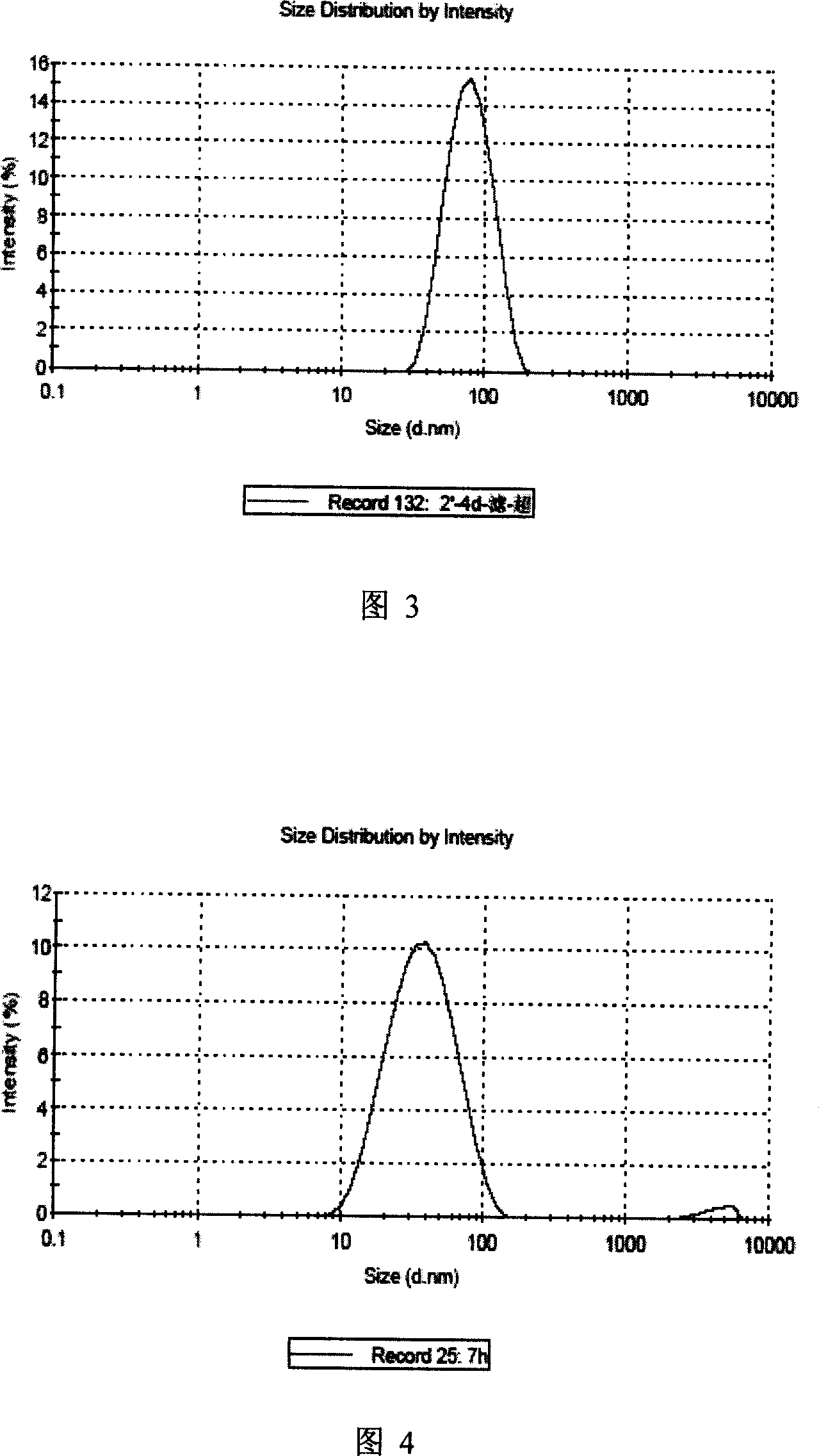

[0038] Take 5mL of polyethyleneimine aqueous solution with a concentration of 6.4g / L and a molecular weight of 1200 in the reactor, deoxidize, and quickly add 2.5mL of FeCl with a concentration of 2.5g / L and a pH of 1 to 3 2 The solution was stirred at room temperature for 1 day to remove unreacted reactants. The particle diameter of the product measured by dynamic light scattering was 71nm, the polydispersity coefficient was 0.13, and the Zeta potential was 33mV (accompanying drawing 3).

Embodiment 3

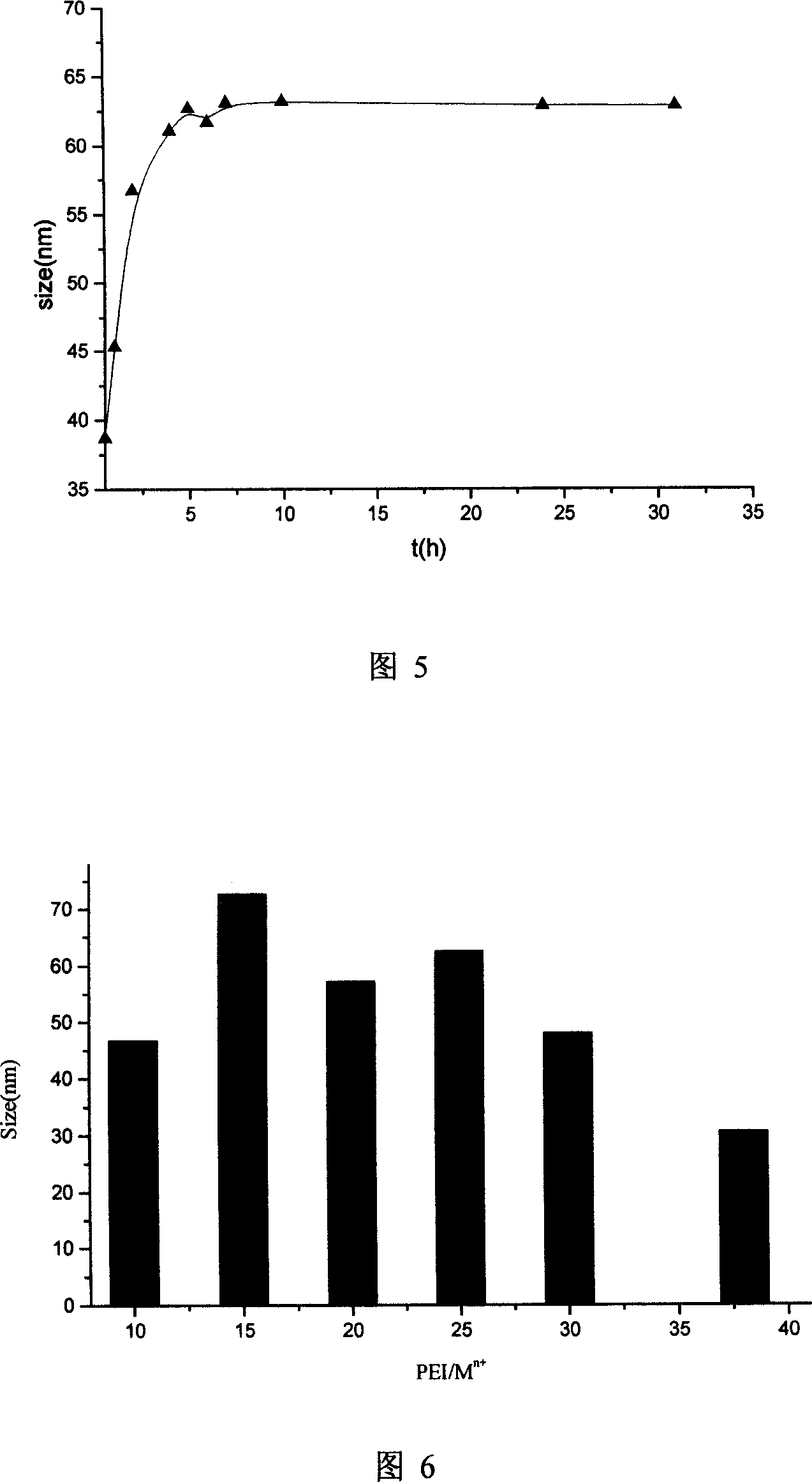

[0040] Take 8mL of polyethyleneimine aqueous solution with a concentration of 6.4g / L and a molecular weight of 2000 in the reactor, deoxidize, and quickly add 1.58mL of FeCl with a concentration of 7.2g / L and a pH of 1 to 3 2 The solution was stirred at room temperature for 1 day to remove unreacted reactants. The particle diameter of the product measured by dynamic light scattering was 30nm, the polydispersity coefficient was 0.27, and the Zeta potential was 32mV (accompanying drawing 4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com