Calcium carbonate powder composition and preparation method thereof

A technology of calcium carbonate powder and composition, applied in the field of calcium carbonate powder composition and preparation thereof, and can solve problems such as coarseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

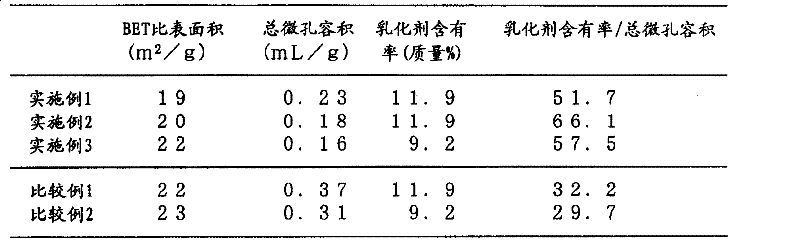

Embodiment 1

[0039] 4m3 of calcium hydroxide aqueous dispersion (milk of slaked lime) with a solid content concentration of 7.4% by mass were stirred at a liquid temperature of 10°C while stirring at a temperature of 1300m 3 The flow rate of / hour introduces the furnace gas that carbon dioxide gas concentration is 26 mass % wherein, introduces 1.5 hours, obtains the calcium carbonate aqueous dispersion liquid that solid content concentration is 10 mass %. The calcium carbonate aqueous dispersion was dehydrated with a rotary filter press to obtain a calcium carbonate dehydrated filter cake with a solid content concentration of 21% by mass. Get a part of this calcium carbonate dehydration filter cake, dry, measure the BET specific surface area of gained calcium carbonate powder, be 33m 2 / g.

[0040]The rest of the calcium carbonate dehydrated filter cake and an emulsifier aqueous solution (emulsifier: a mixture of sucrose fatty acid ester and glycerin fatty acid ester, リヨ-トシュガ-エステルSEM-7...

Embodiment 2

[0043] Change the pressure of the aqueous dispersion jet stream into 200MPa during the impact collision dispersion treatment, except that, carry out the impact collision dispersion treatment in the same manner as in Example 1, dry with a spray drier, and prepare a calcium carbonate powder composition.

[0044] The BET specific surface area, total micropore volume and emulsifier content were measured for the obtained calcium carbonate powder composition by the above-mentioned method. As a result, the BET specific surface area is 20m 2 / g, the total pore volume was 0.18mL / g, and the emulsifier content was 11.9% by mass.

Embodiment 3

[0046] The mixing ratio of the emulsifier aqueous solution is such that the concentration of the emulsifier is 1.5% by mass relative to the total amount (about 9.1% by mass relative to the total amount of calcium carbonate powder and emulsifier), and the concentration of the aqueous dispersion jet during the impact collision dispersion process is 1.5% by mass. The pressure was 200MPa, and the impact collision dispersion treatment was performed in the same manner as in Example 1, and dried with a spray dryer to prepare a calcium carbonate powder composition.

[0047] The BET specific surface area, total micropore volume and emulsifier content were measured for the obtained calcium carbonate powder composition by the above-mentioned method. As a result, the BET specific surface area is 22m 2 / g, the total pore volume was 0.16 mL / g, and the emulsifier content was 9.2% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com