Optical sheet for surface light source apparatus

An optical sheet and transparent technology, applied in optics, nonlinear optics, planar/plate light guides, etc., can solve problems such as brightness reduction, achieve the effects of enhancing brightness and viewing angle, reducing production costs, and reducing the thickness of backlight units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

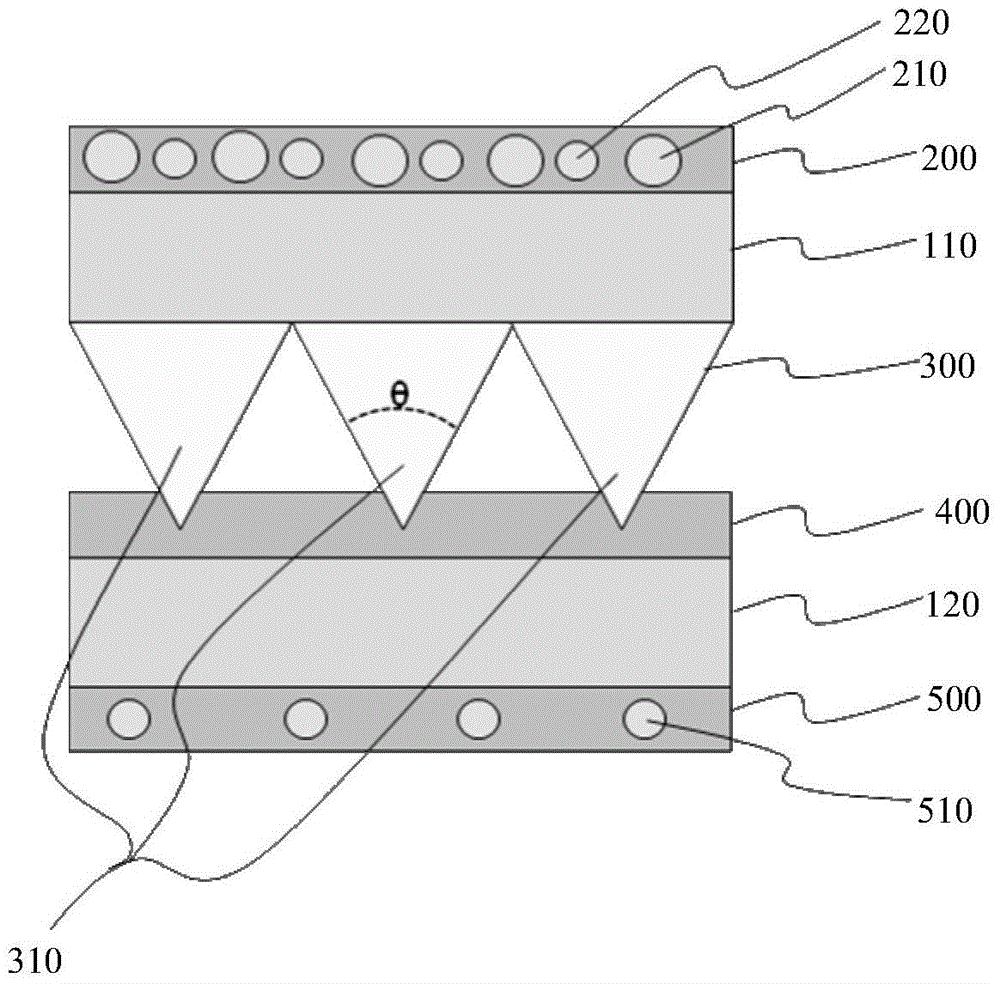

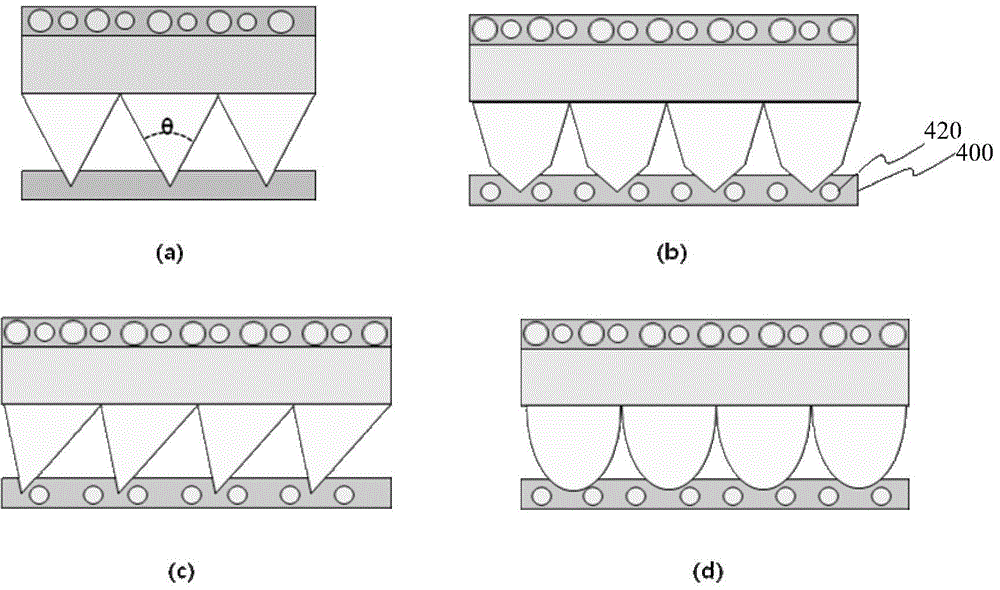

[0030] Hereinafter, each component of the optical sheet of the present invention will be described in detail.

[0031] (1) Transparent support film

[0032] The transparent supporting film used in the present invention is mainly transparent plastic. The transparent support film must have good adhesion and surface smoothness for the adhesive resin with a rear incident light transmittance of more than 90% to prevent brightness changes. The thickness of the transparent supporting film is preferably between 50-250 μm. The materials suitable for the transparent support film include polyethersulfone (PES), polyacrylate (PAR), polyetherimide (PEI), polyethylene naphthalate (PEN), polyethylene terephthalate Alcohol ester (PET), polyphenylene sulfide (PPS), polyallylate (polyallylate), polyimide, polycarbonate (PC), triacetate cellulose (TAC), cellulose acetate propionate (CAP ) and mixtures thereof, preferably PET.

[0033] (2) Diffusion layer

[0034] In the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com