Temperature controllable deep cooling treatment system bases on natural circulation

A technology of cryogenic treatment and natural circulation, applied in the field of temperature-controlled cryogenic treatment systems, can solve the problems of slow heat transfer rate by radiation cooling method, and it is difficult to achieve rapid cooling, saving liquid nitrogen consumption, facilitating the regulation of treatment temperature, The effect of saving cycle power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

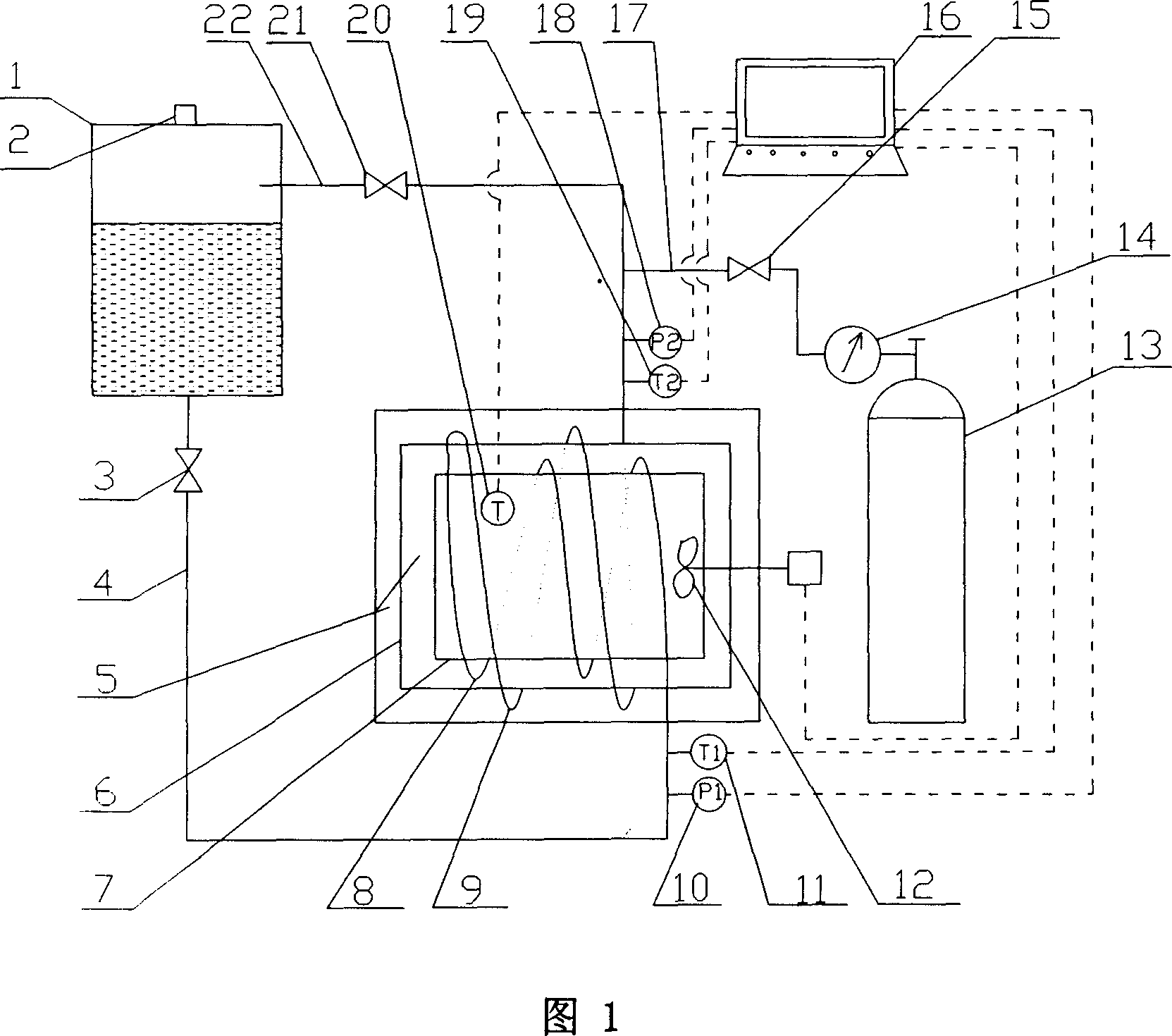

[0011] The present invention utilizes the difference in the density of liquid nitrogen and gas nitrogen to form a pressure difference to push the liquid nitrogen coolant to circulate, that is, the so-called natural circulation, and the gas nitrogen is generated by the process of cooling workpieces with liquid nitrogen without external heat source. At the same time, the method of combining radiation cooling and forced convection cooling is adopted to realize the control of cooling rate and processing temperature, and ensure the uniform distribution of temperature in the cryogenic processing chamber.

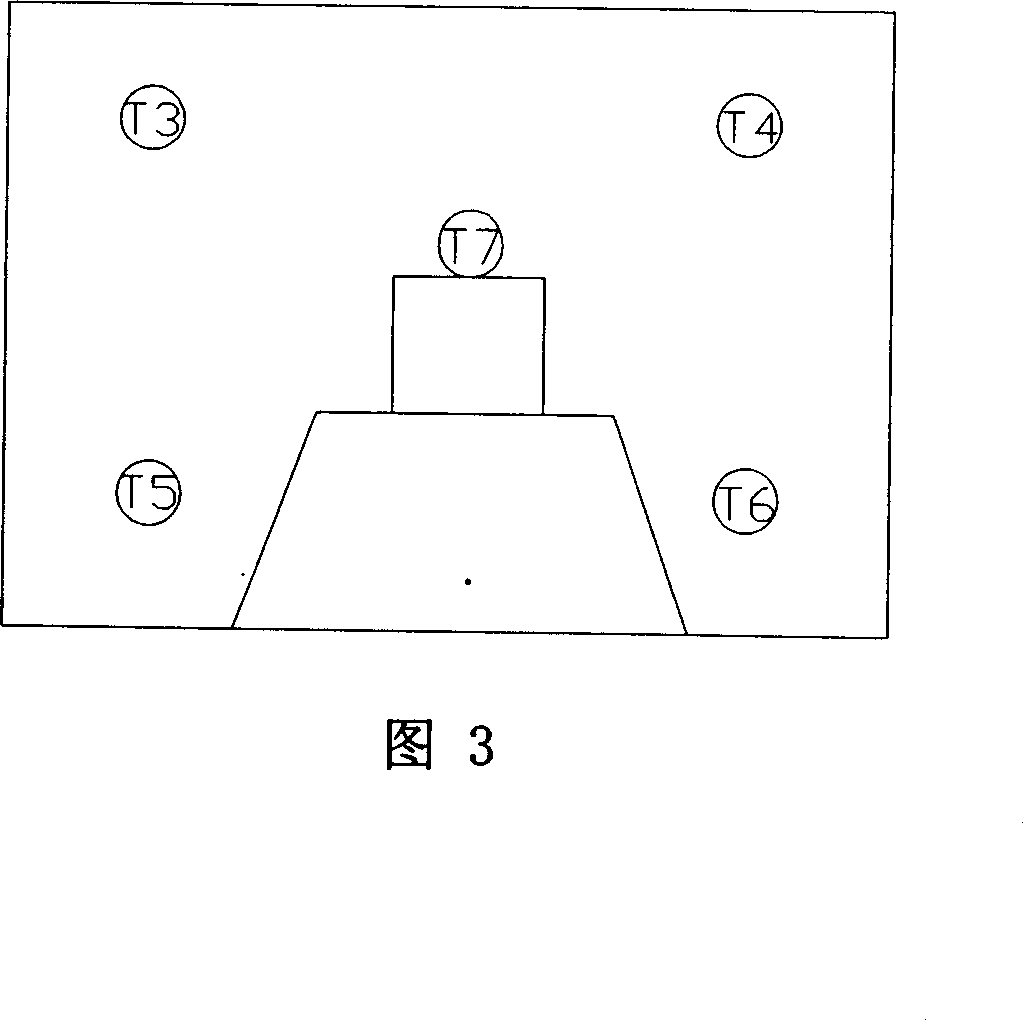

[0012] As shown in Figure 1, the temperature-controllable cryogenic treatment system based on natural circulation is characterized in that it includes a liquid nitrogen storage tank 1, a liquid injection port 2, an infusion valve 3, an infusion tube 4, an insulating layer 5, a cold shield 6, Cryogenic treatment chamber 7, inner coil 8, outer coil 9, inner coil inlet pressure sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com