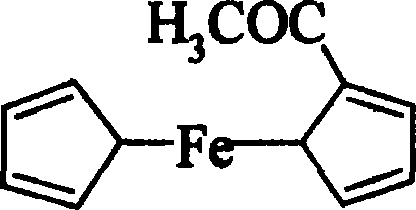

Preparation method of acetyl cyclopentadienyl iron

A kind of acetyl ferrocene, said technology, applied in the direction of chemical instruments and methods, metallocene, organic chemistry, etc., can solve the problems of unsatisfactory industrialization prospects, difficult post-processing separation, cumbersome operation, etc., and achieve the elimination of purification operation Steps, inhibition of side reactions, good product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

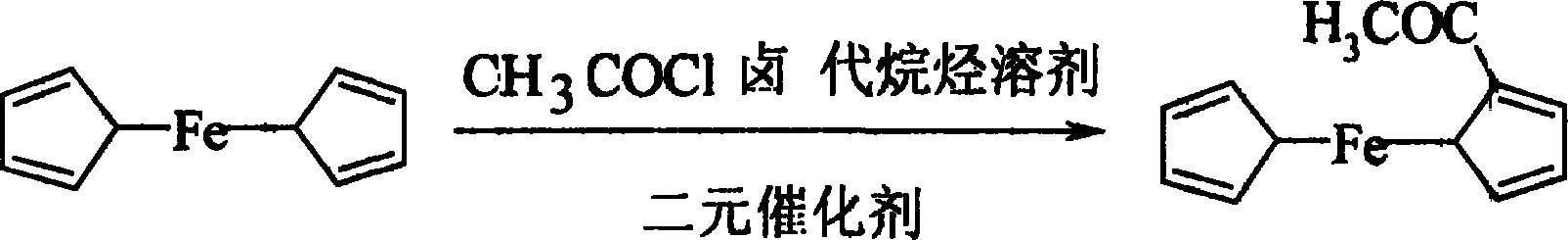

Method used

Image

Examples

Embodiment 1

[0020] Add 125ml of dichloromethane reaction solvent in the 500ml four-port reactor with cooling, thermometer, stirrer, gas inlet tube, add 0.1mol (18.6g) ferrocene under stirring, import nitrogen, under nitrogen atmosphere, cool to -8°C, within 3 hours, slowly drop into the mixed solution composed of the acetylation reagent acetyl chloride and the binary catalyst solution. g) Anhydrous aluminum trichloride, 0.0107mol (1.52g) 47% boron trifluoride ether solution>, warm up to 20°C, maintain the temperature for 3 hours, add 10ml of water dropwise under stirring, filter, evaporate the reaction solvent, 20ml of 30-60°C petroleum ether was added, yellow crystals were precipitated, and dried to obtain 21.1 g of acetylferrocene, with a yield of 92.0%, a purity of 99.3% (HPLC), and a melting point of 86-87°C.

Embodiment 2

[0022] Add 125ml of dichloromethane into a 500ml four-port reactor with cooling, thermometer, stirrer, and gas inlet tube, add 0.1mol (18.6g) of ferrocene under stirring, introduce nitrogen, and cool to 0°C under nitrogen atmosphere , within 4 hours, drop the mixed solution of the acetylation reagent acetyl chloride and the binary catalyst solution. Aluminum trichloride, 0.02mol (2.84g) 47% boron trifluoride ether solution>, warming up to 20°C, maintaining the temperature for 2 hours, adding 10ml of water dropwise under stirring, filtering, distilling off the reaction solvent, adding 20ml of 30 Petroleum ether at -60°C precipitated yellow crystals and dried to obtain 20.4 g of acetylferrocene, with a yield of 89.1%, a purity of 98.3% (HPLC), and a melting point of 85-87°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com