Method for preparing LED electrode

A technology for manufacturing light-emitting diodes and electrodes, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problem of wire plate falling off, etc., and achieve the effect of firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

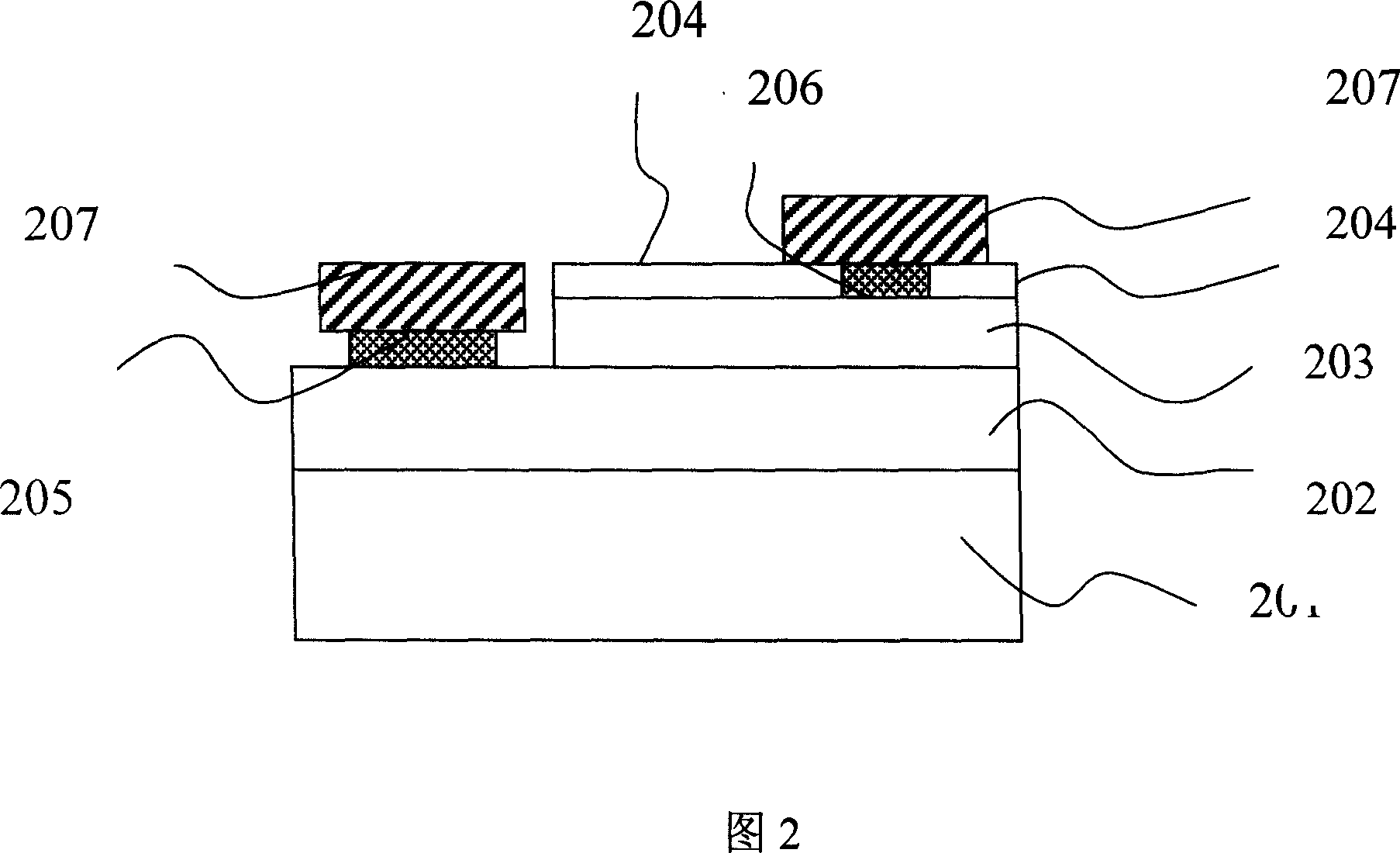

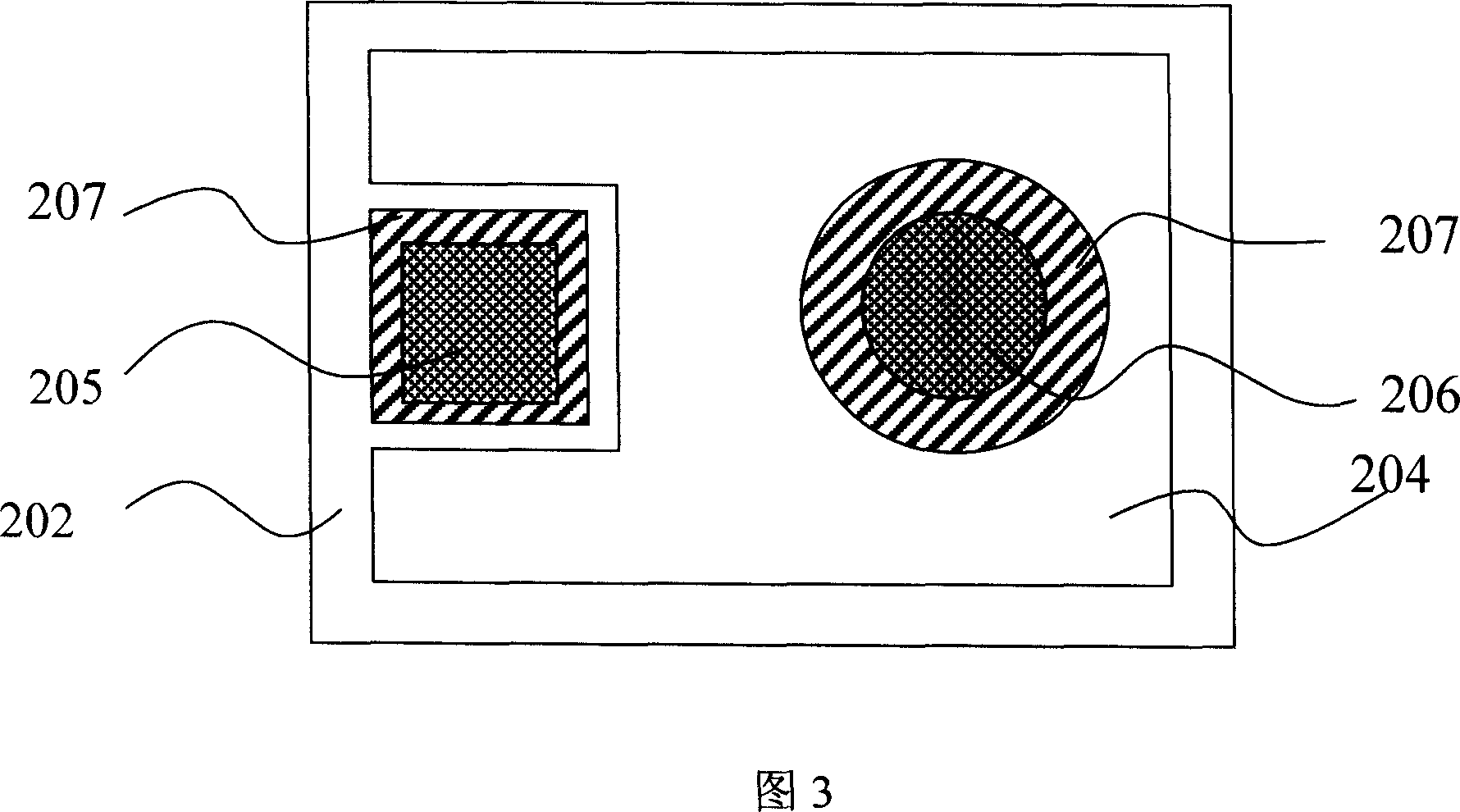

[0025] An electrode structure and manufacturing method of a gallium nitride light-emitting diode chip includes the following processes, and the structure refers to FIG. 2:

[0026] 1. Grow N-type gallium nitride (202) and P-type gallium nitride (203) on a sapphire substrate (201), and then vapor-deposit Ni / The Au metal layer (204), with a thickness of 50-500 Ȧ, is then annealed in an air environment at a temperature of 250-700° C. for 10-40 minutes to form a transparent P-type ohmic contact layer; and then evaporated by an electron beam Method A Ti / Ni / Al metal layer (205) is vapor-deposited on the N+ layer of the gallium nitride epitaxial wafer with a thickness of 100-5000 Ȧ to form an N-type ohmic contact layer.

[0027] 2. Use photolithography and wet etching to remove part of the ohmic contact electrode layer at the position where the P bonding pad is prepared, exposing the P-type gallium nitride epitaxial layer, whose size is smaller than the size of the P bonding pad.

...

Embodiment 2

[0035] An electrode structure and manufacturing method of a gallium nitride light-emitting diode chip includes the following processes, and the structure refers to FIG. 4:

[0036] 1. Grow N-type gallium nitride (202) and P-type gallium nitride (203) on a sapphire substrate (201), and then vapor-deposit Ni / The Au metal layer (204), with a thickness of 50-500 Ȧ, is then annealed in an air environment at a temperature of 250-700° C. for 10-40 minutes to form a transparent P-type ohmic contact layer; and then evaporated by an electron beam Method A Ti / Ni / Al metal layer (205) is vapor-deposited on the N+ layer of the gallium nitride epitaxial wafer with a thickness of 100-5000 Ȧ to form an N-type ohmic contact layer.

[0037] 2. Use photolithography and wet etching to remove part of the ohmic contact electrode layer at the position where the P bonding pad is prepared, exposing the P-type gallium nitride epitaxial layer, whose size is smaller than the size of the P bonding pad.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com