Method for preparing high purity chymotrypsin

A high-purity technology of chymotrypsin, applied in the field of biopharmaceuticals, to achieve the effect of simplifying the process, reducing production costs and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

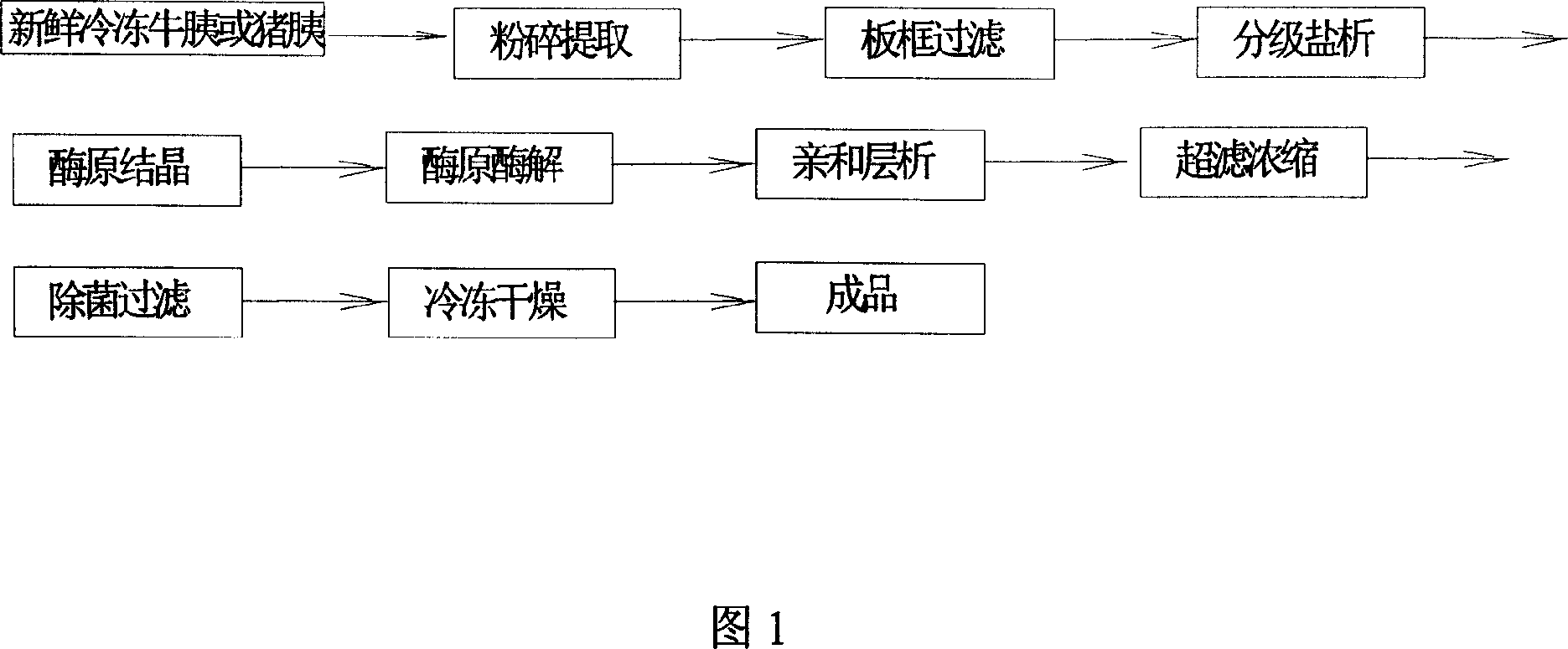

Image

Examples

Embodiment 1

[0036] Take 150 kg of fresh frozen beef pancreas. These beef pancreas are purchased from professional animal husbandry or meat companies with good quality assurance and complete animal quarantine certificates. The transportation of raw materials is refrigerated and the storage conditions are frozen. Frozen raw materials are crushed directly. Add 450L of pre-cooled 0.25N sulfuric acid solution, transfer to a 1-ton stirring container, stir and extract in a 4°C freezer for 3 hours, and place it overnight. The next day, filter with plate and frame filter equipment instead of bag filter in the traditional process. The separated residue is bagged and treated according to environmental protection requirements. The obtained clear liquid is stirred and added with ammonium sulfate to 30% saturation, and a small amount of diatomaceous earth is added. As a filter aid, place in a 4°C freezer overnight and then filter to obtain the extract. Add ammonium sulfate to the extract to 70% satura...

Embodiment 2

[0038] Take 450 kg of fresh frozen bovine pancreas, and use a pulverizer to directly pulverize the frozen raw materials into a slurry. Add 1350L of pre-cooled 0.25N sulfuric acid solution, transfer to a 2-ton stirring container, stir and extract in a 4°C refrigerator for 5 hours, and place it overnight. The next day, use a plate-and-frame filter to filter. The separated residue is bagged and treated according to environmental protection requirements. Stir and add ammonium sulfate to the clear liquid to 30% saturation, and add a small amount of diatomaceous earth to filter, and place it in a cold storage at 4°C. After overnight, the extract was obtained by filtration. Add ammonium sulfate to the extract to 70% saturation, place it in a 4°C freezer overnight, absorb the supernatant the next day, discard it, and centrifuge to obtain 23 kg of precipitate. Dissolve the precipitate with 34.5 L of ice water, and then add 11.5 kg of saturated ammonium sulfate solution to adjust the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com