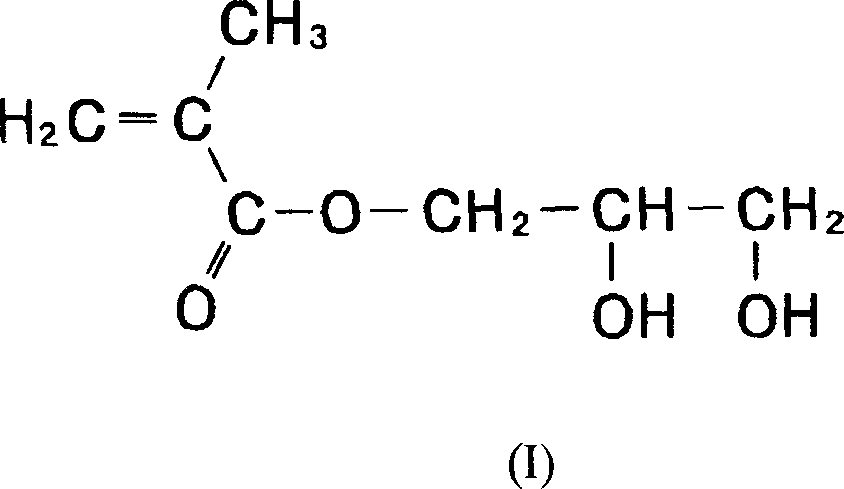

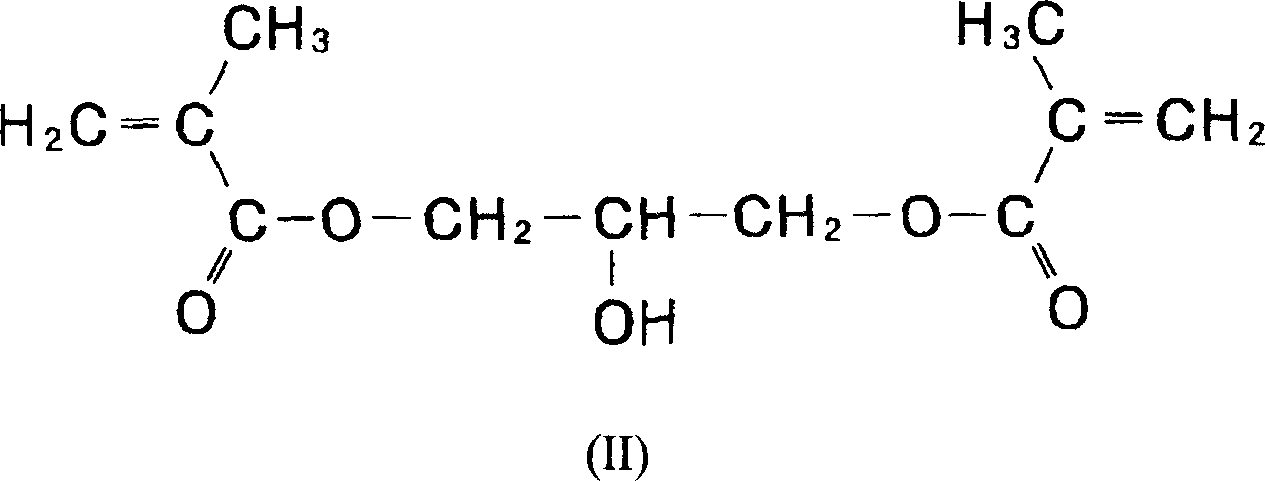

Printing ink using ultraviolet cured resin composition as active ingradient

A curable resin and printing ink technology, which can be used in ink, household utensils, applications, etc., and can solve problems such as difficult and environmentally friendly combinations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0075] As the ultraviolet curable resin composition of the present invention, printing inks having the formulations (unit: % by weight) shown in Examples 1 to 9 in Tables 2 to 4 below were prepared.

[0076]Prepare a polypropylene board, polyethylene board, and ethylene-vinyl alcohol copolymer board with a thickness of 1.5mm as printing materials, and perform pretreatment so that the above materials are wetted by the printing surface Tension: 40mN / m for polypropylene board, polyethylene The board is 46 mN / m, and the ethylene-vinyl alcohol copolymer material is 46 mN / m. Thereafter, using a 460-mesh screen board, the printing ink of each example was printed on the printed surface of each printing material by a screen printing method to obtain a printed matter.

[0077] The above-mentioned printed matter was passed through the conveyor belt once at a speed of 5 m / min under a metal halide lamp of 80 W / cm1 lamp, and irradiated with ultraviolet rays to form a cured coating film (pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com