Double micro pore high silicon composite molecular sieve and its preparing method

A molecular sieve and high-silicon technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of difficult post-treatment process and poor hydrothermal stability, and achieve good thermal and hydrothermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

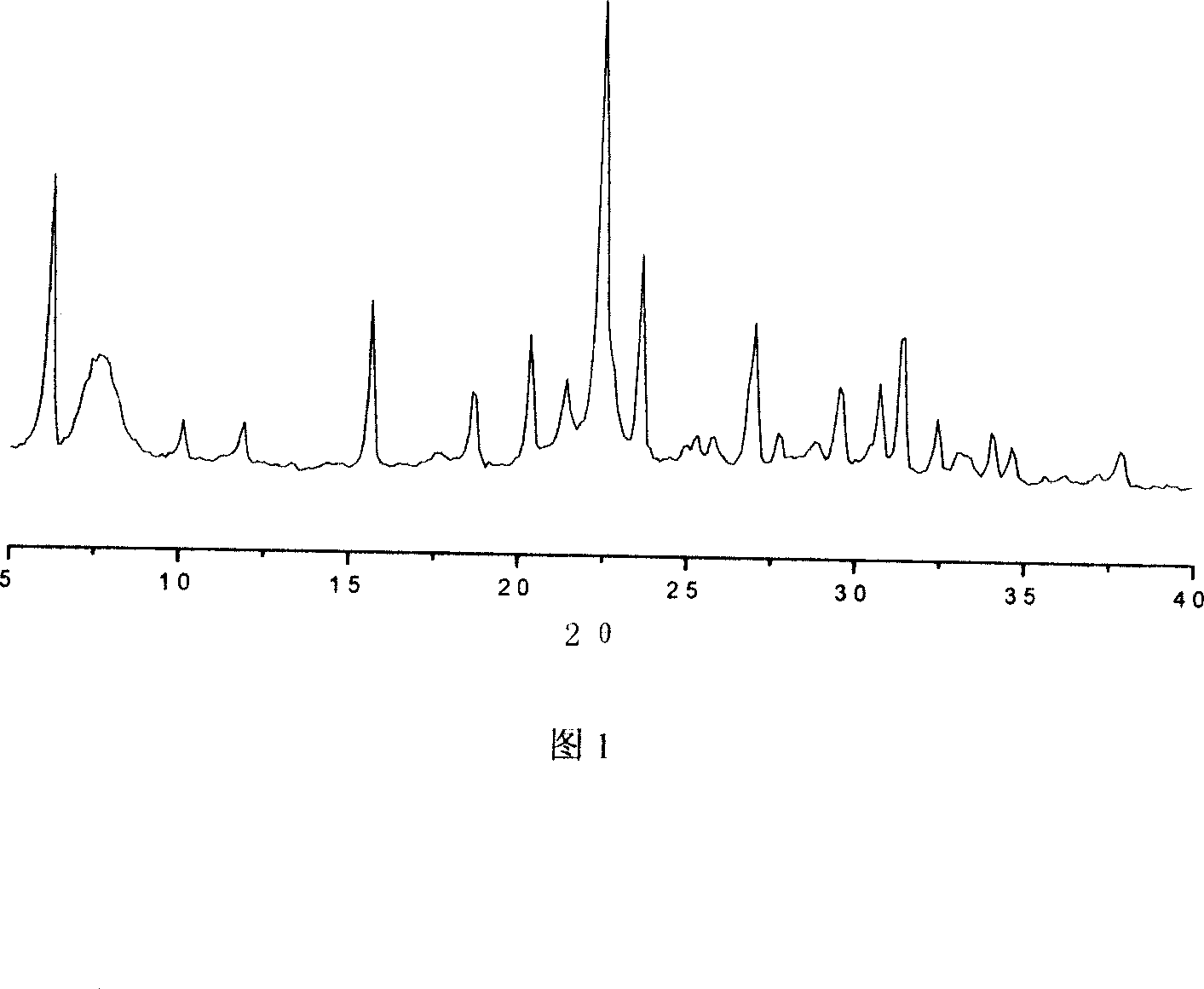

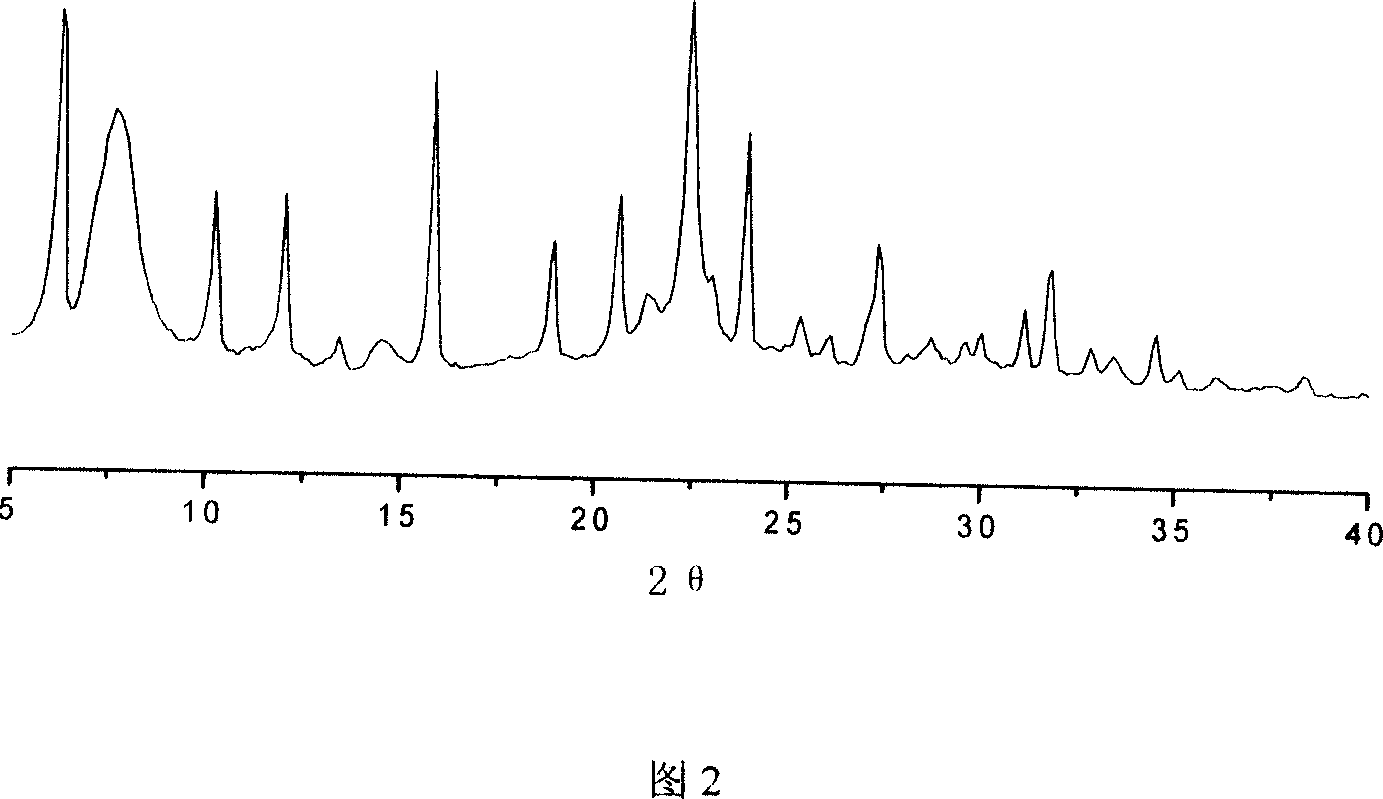

Image

Examples

Embodiment approach 1

[0015] In the first step, mix 13.0g of high-silicon Y zeolite powder and 90.0ml of NaOH (0.10mol / L) evenly, stir with magnetic force for 1 hour, put the mixed solution into a 150ml stainless steel reaction kettle, and dissolve it in alkali at 180°C for 3 hours . Obtain a high-silicon Y zeolite whose crystallinity decreases after alkali dissolution;

[0016] In the second step, the obtained high-silicon Y zeolite whose crystallinity is reduced after alkali dissolution is centrifuged with a centrifuge, and the supernatant is removed;

[0017] The 3rd step adds 0.6g sodium hydroxide on the basis of the high silicon Y zeolite that crystallinity reduces after the alkali dissolution that makes, 10.0gTEABr (tetraethylammonium bromide), 10.0ml strong ammoniacal liquor, 28.0ml silica sol ( [SiO 2 ]=5.80mol / L), 16.0ml of distilled water were mixed and stirred into a uniform white jelly, put into a 150ml stainless steel reaction kettle, crystallized at 140°C for 6 days, taken out, wash...

Embodiment approach 2

[0019] In the first step, mix 13.0g of high-silicon Y zeolite powder and 90.0ml of NaOH (0.10mol / L) evenly, stir with magnetic force for 1 hour, put the mixed solution into a 150ml stainless steel reaction kettle, and dissolve it in alkali at 175°C for 4 hours . Obtain a high-silicon Y zeolite whose crystallinity decreases after alkali dissolution;

[0020] In the second step, the obtained high-silicon Y zeolite whose crystallinity is reduced after alkali dissolution is centrifuged with a centrifuge, and the supernatant is removed;

[0021] The 3rd step adds 0.4g sodium hydroxide on the basis of the high silicon Y zeolite that crystallinity reduces after the alkali dissolution that makes, 10.0gTEABr (tetraethylammonium bromide), 10.0ml strong ammoniacal liquor, 28.0ml silica sol ( [SiO 2 ]=5.80mol / L), 16.0ml of distilled water were mixed and stirred into a uniform white jelly, put into a 150ml stainless steel reaction kettle, crystallized at 140°C for 6 days, taken out, wash...

Embodiment approach 3

[0023] In the first step, mix 13.0g high-silicon Y zeolite powder and 90.0ml NaOH (0.10mol / L) evenly, stir with magnetic force for 1 hour, put the mixed solution into a 150ml stainless steel reaction kettle, and dissolve it in alkali at 140°C for 20 Hours. Obtain a high-silicon Y zeolite whose crystallinity decreases after alkali dissolution;

[0024] In the second step, the obtained high-silicon Y zeolite whose crystallinity is reduced after alkali dissolution is centrifuged with a centrifuge, and the supernatant is removed;

[0025] The 3rd step adds 0.8g sodium hydroxide on the basis of the high silicon Y zeolite that crystallinity reduces after the alkali dissolution that makes, 10.0gTEABr (tetraethylammonium bromide), 10.0ml strong ammoniacal liquor, 28.0ml silica sol ( [SiO 2 ]=5.80mol / L), 16.0ml of distilled water were mixed and stirred into a uniform white jelly, put into a 150ml stainless steel reaction kettle, crystallized at 140°C for 8 days, taken out, washed unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com