Method for making aluminum plastic plate handicraft and its aluminum plastic plate handicraft

A technology for handicrafts and aluminum-plastic panels, which is applied in the manufacture of aluminum-plastic panel handicrafts and in the field of aluminum-plastic panel handicrafts, can solve the problems of destroying the metal texture of aluminum alloys, reducing the strength, and having no three-dimensional effect on the surface of the handicrafts, so as to achieve a strong three-dimensional effect of patterns. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

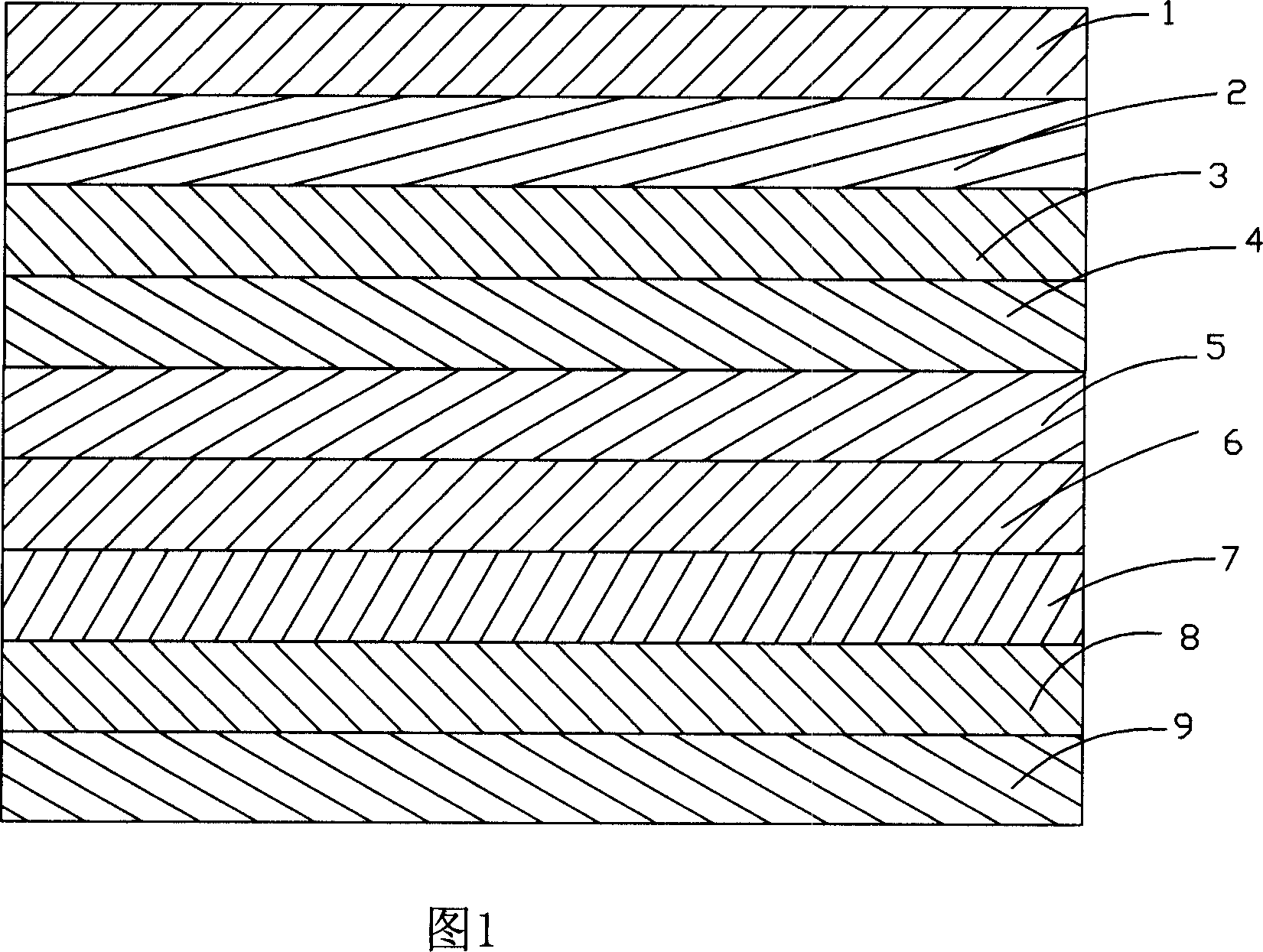

[0021] As shown in Figure 1, the structure of the existing aluminum-plastic panel is: from top to bottom protective film 1, fluorinated vinyl resin baking paint layer 2, primer 3, oxidation treatment film layer 4, aluminum alloy plate 5, plastic base Material 6, aluminum alloy plate 7, oxidized film layer 8, and primer 9 are composed of nine layers.

[0022] Utilize the existing aluminum-plastic plate, remove the protective film 1, fluorinated vinyl resin baking paint layer 2, primer 3, and oxidation treatment film layer 4 on the aluminum alloy plate 5, and then process the aluminum alloy plate 5.

[0023] A method for making an aluminum-plastic panel handicraft, the steps of which are as follows:

[0024] (1) Remove the uppermost protective film of the aluminum-plastic panel, the fluorinated vinyl resin baking paint layer, the primer, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com